Connecting device of steel column butt joint and installing method

A technology of a connecting device and an installation method, applied in the directions of columns, piers, pillars, etc., can solve the problems of the impact of three-dimensional crossing operations, large construction measures and labor, and difficulty in installation accuracy, so as to save measures and labor costs, and avoid construction crossings. Work and improve construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] This embodiment provides a connecting device for butt jointing of steel columns, which is used for butt jointing of an upper steel column (which can be a vertical or inclined upper steel column) on a fixed lower steel column in the construction of a steel structure building, so that the upper steel column The steel column is temporarily fixed on the lower steel column, such as Figure 2~4 As shown, the connecting device includes: lug plate, connecting splint and bolt;

[0023] Among them, there are two ear plates, and the ear plates can be rectangular steel plates. The thickness of the ear plates is generally 20-30mm. Both ear plates are provided with bolt holes, and there are multiple bolt holes, which are evenly distributed on the ear plates. ;

[0024] There are also two connecting splints, and the connecting splints can also be rectangular steel plates. The thickness of the connecting splints is generally 12-18mm. Bolt holes are also provided on the two connecting ...

Embodiment 2

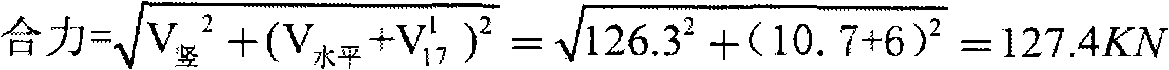

[0031] This embodiment provides a steel column butt joint installation method, which is used for butt installation of an inclined upper steel column on a fixed lower steel column, such as Figure 5 As shown, the steps of the method are as follows, specifically including:

[0032] The butt joints of the upper and lower steel columns to be connected are fixedly connected by the connection device provided in the first embodiment above;

[0033] Step S1, welding the lug plates of the connecting device to the butt ends of the butted upper and lower steel columns respectively;

[0034] Step S2, hoisting the upper steel column above the fixed lower steel column, adjusting the upper steel column to the installation position, so that the position of the ear plate welded at the butt end of the upper steel column corresponds to the position of the ear plate welded at the butt end of the lower steel column;

[0035] Step S3, clamping the lug plates welded at the butt ends of the upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com