Hydraulic creeping formwork system and creeping formwork construction method

A hydraulic climbing formwork and climbing formwork technology, applied in the field of climbing formwork systems, can solve the problems of a large number of climbing devices, inconvenient installation and disassembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in detail below in conjunction with the accompanying drawings:

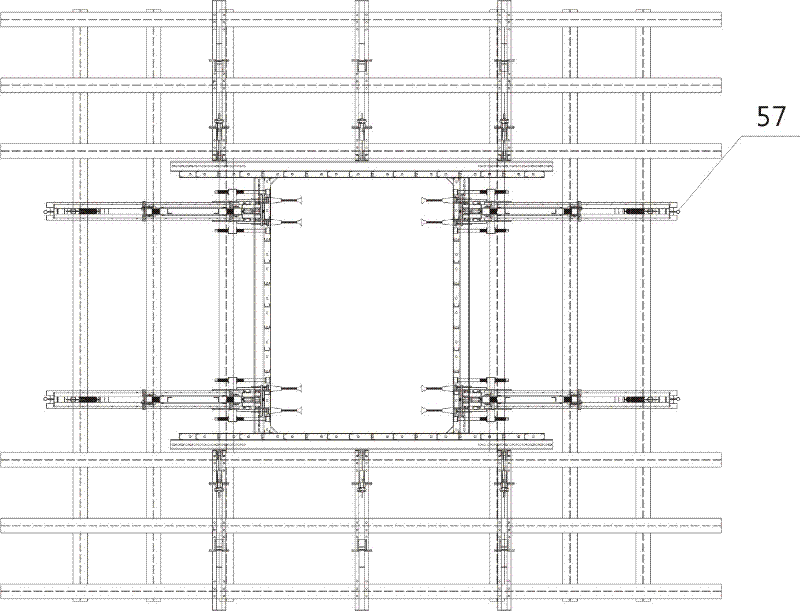

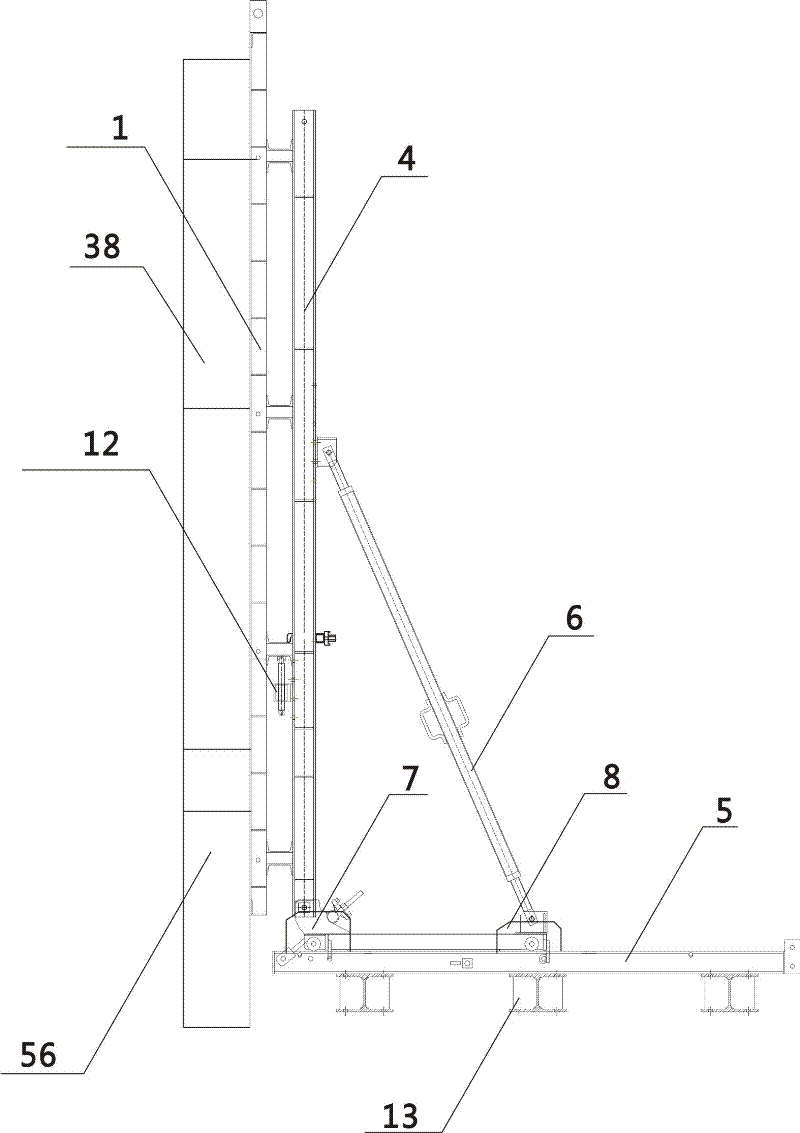

[0040] The present invention provides a hydraulic climbing formwork system with simple structure, convenient maintenance, and convenient installation and disassembly. The hydraulic climbing formwork system consists of four climbing formwork devices attached to the surface of the wall and 4 positions to form the climbing formwork system, and the four positions are installed on the climbing formwork devices on the lateral sides of the climbing formwork system.

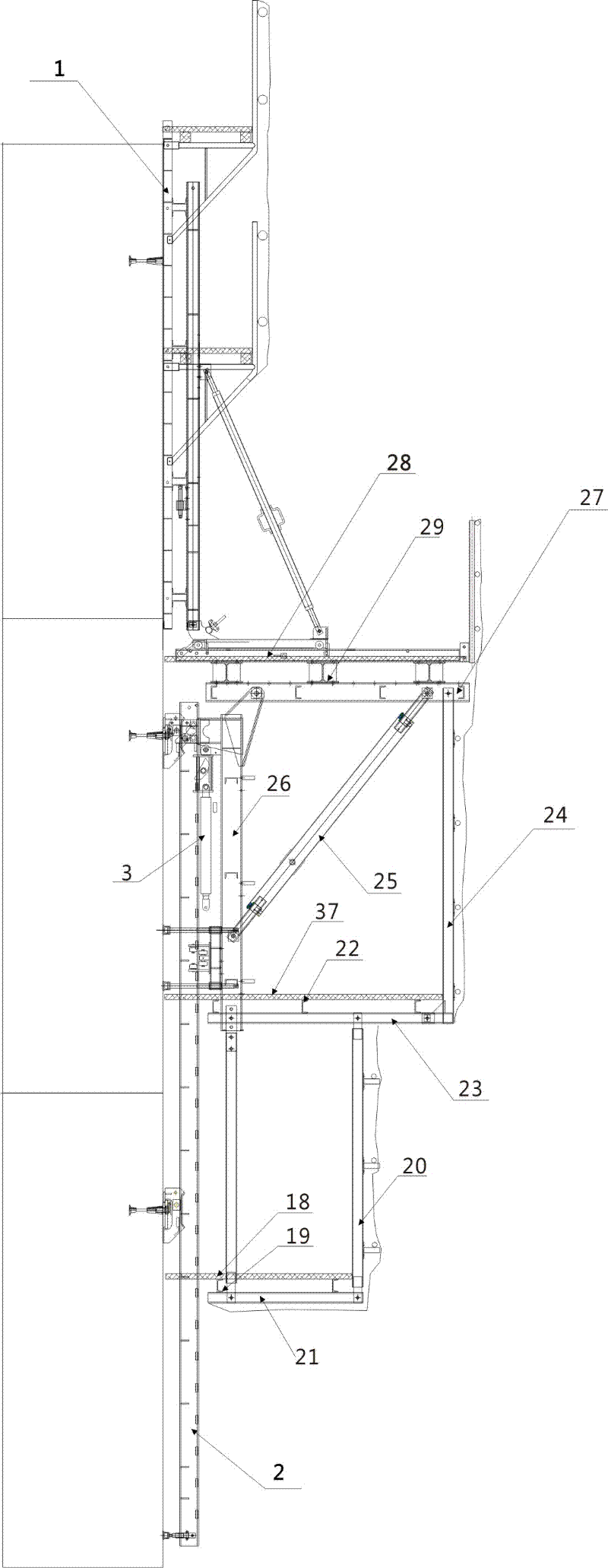

[0041] like image 3Shown: The climbing formwork device of the present invention includes a formwork 1 located at the upper end of the whole device for concrete pouring and a working platform composed of a steel structure, and also includes a formwork 1 for installing and supporting the formwork 1 for concrete pouring when pouring concrete. After completion, the template moving bracket for demoulding the template a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com