Crossover stringing method for overhead line and stringing sheave pulley

An overhead line and spanning technology, applied in the direction of overhead line/cable equipment, etc., can solve the problems of prone to major accidents, complicated spanning lines, long construction time, etc., so as to shorten the power failure spanning time, good economy and construction cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

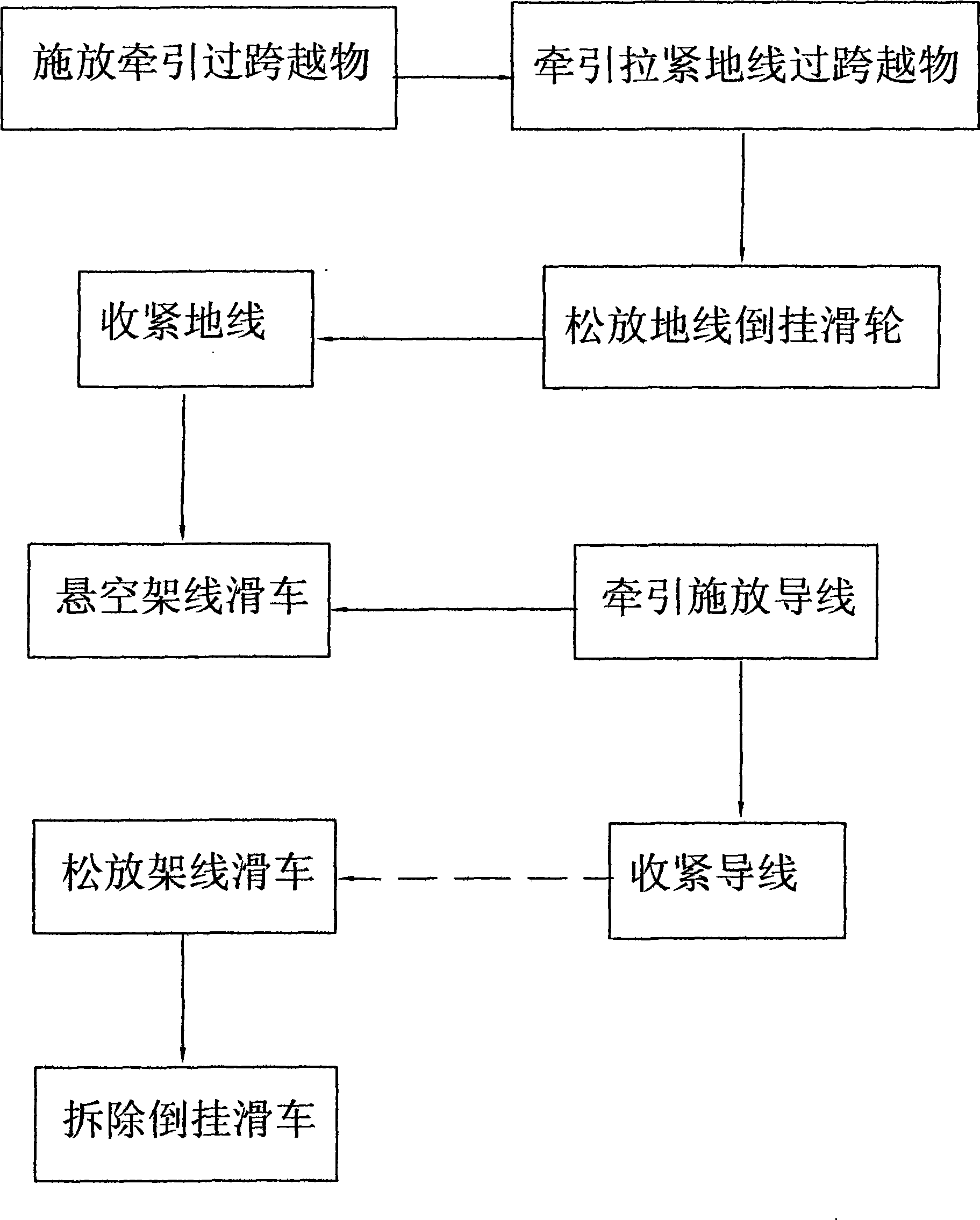

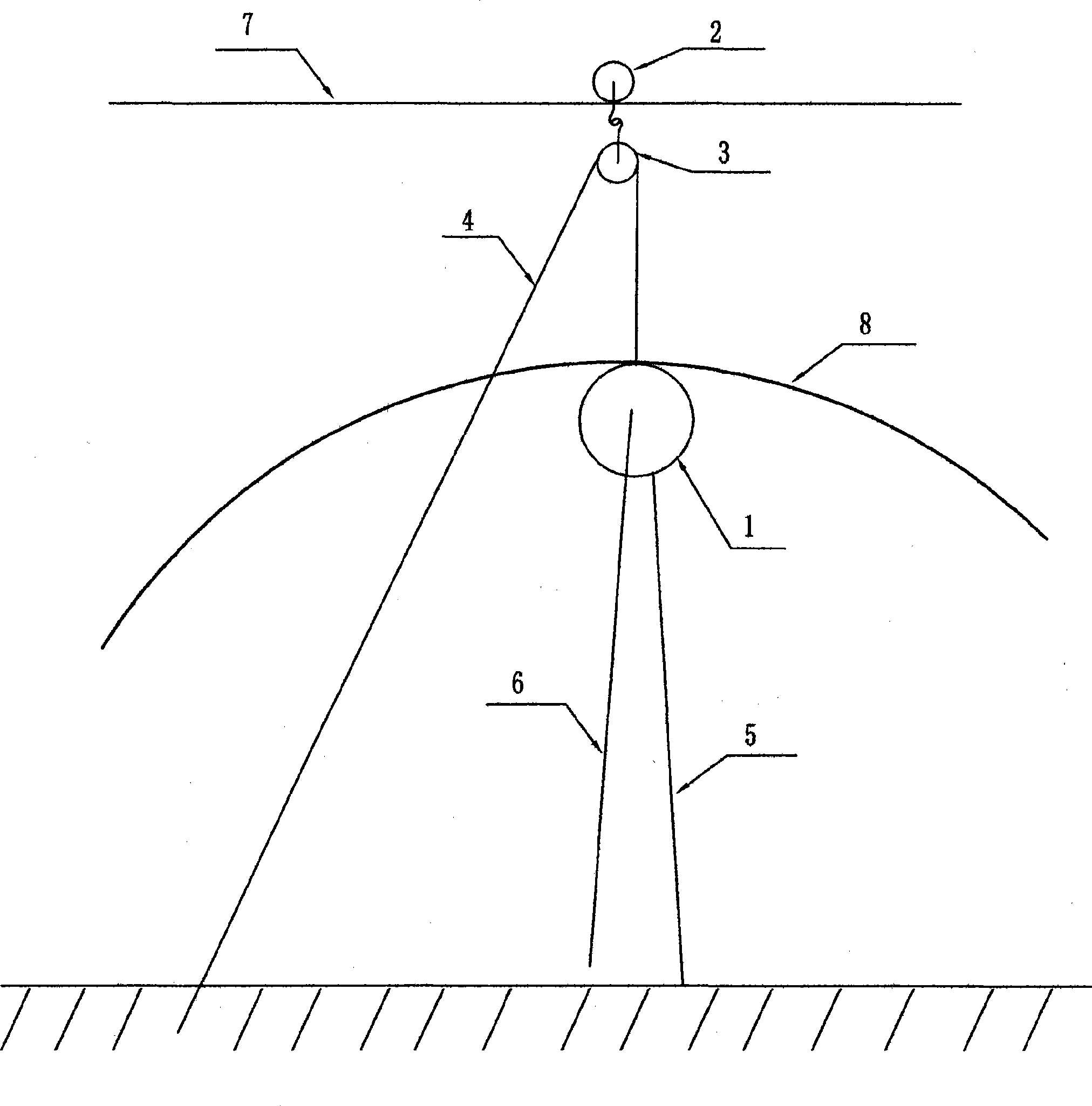

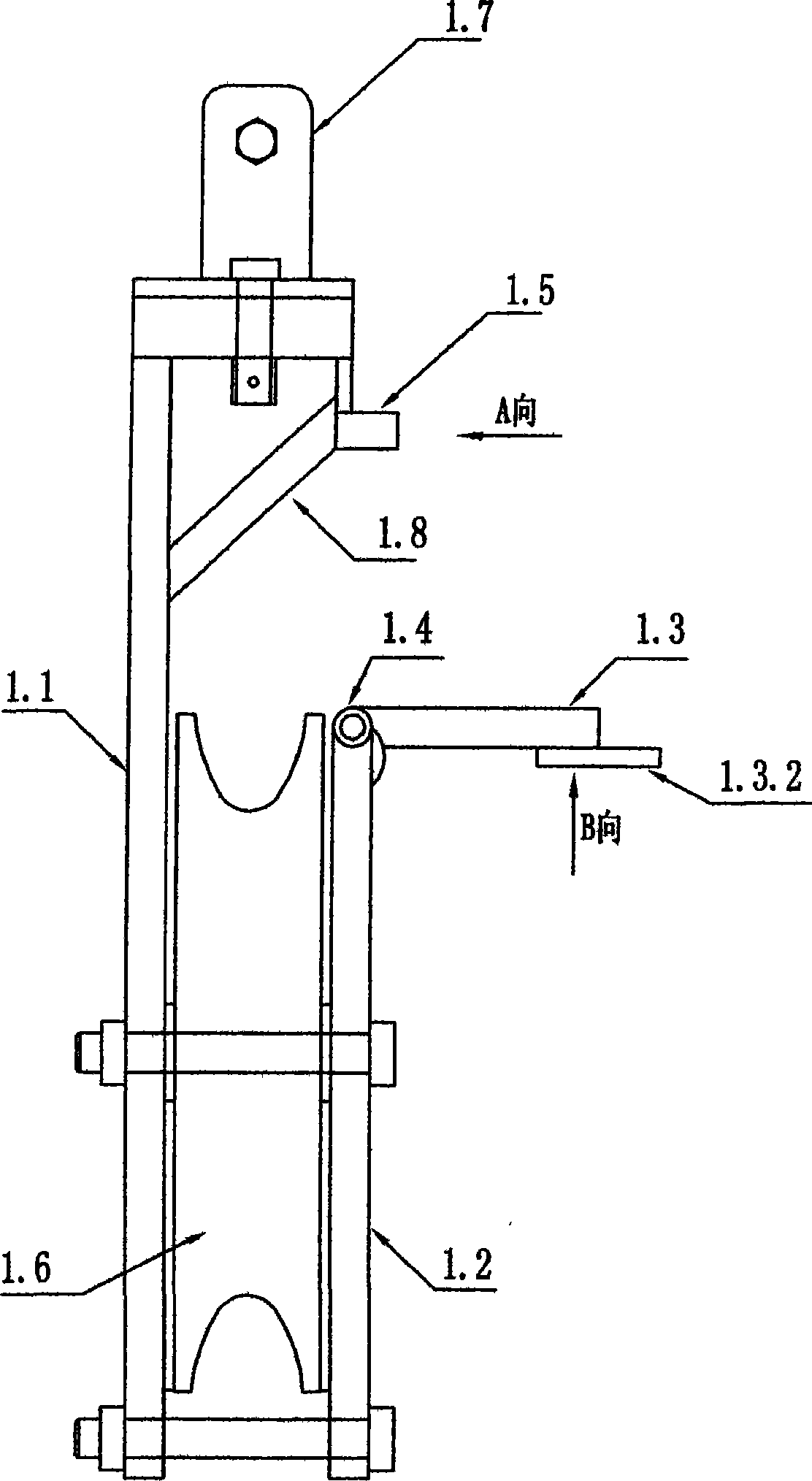

[0029] Example: see figure 1 , 2 , 3, 4, the overhead line of the present invention straddles the strung method, as figure 1 The procedure is to take crossing overhead lines as an example. First, a GY communication optical cable is cast over the side of the crossed line through a projectile gun, and one end of the optical cable is connected to the ground wire 7 (you can also connect a traction cable first, and then connect the ground wire). The tower pole pulls the optical cable and at the same time slightly brakes the ground wire coil, so that the ground wire is forced to pass through the crossed line until the ground wire reaches the tower pole, and the traction is stopped. Loosen the ground wire to the ground, hang a tackle 2 upside down on the ground wire 7, hang the tackle 3 on the upside down tackle 2, penetrate an extradition rope in the tackle 3, and tighten the ground wire 7. Pull the extradition cord and replace it with a steel wire rope 4, one end of the steel wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com