Whole high-cleanliness electronic plant steel structure slippage and detachment method

A technology with overall slippage and high cleanliness, which is applied in the direction of building structure, construction, and building materials processing, etc. It can solve the problems that the crane cannot be hoisted nearby, the construction period cannot be guaranteed, and the construction efficiency is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

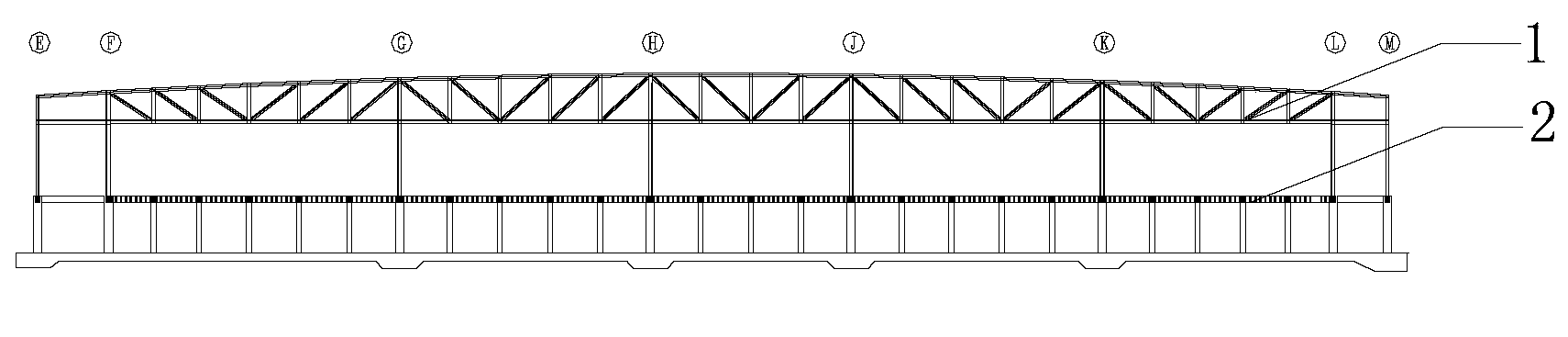

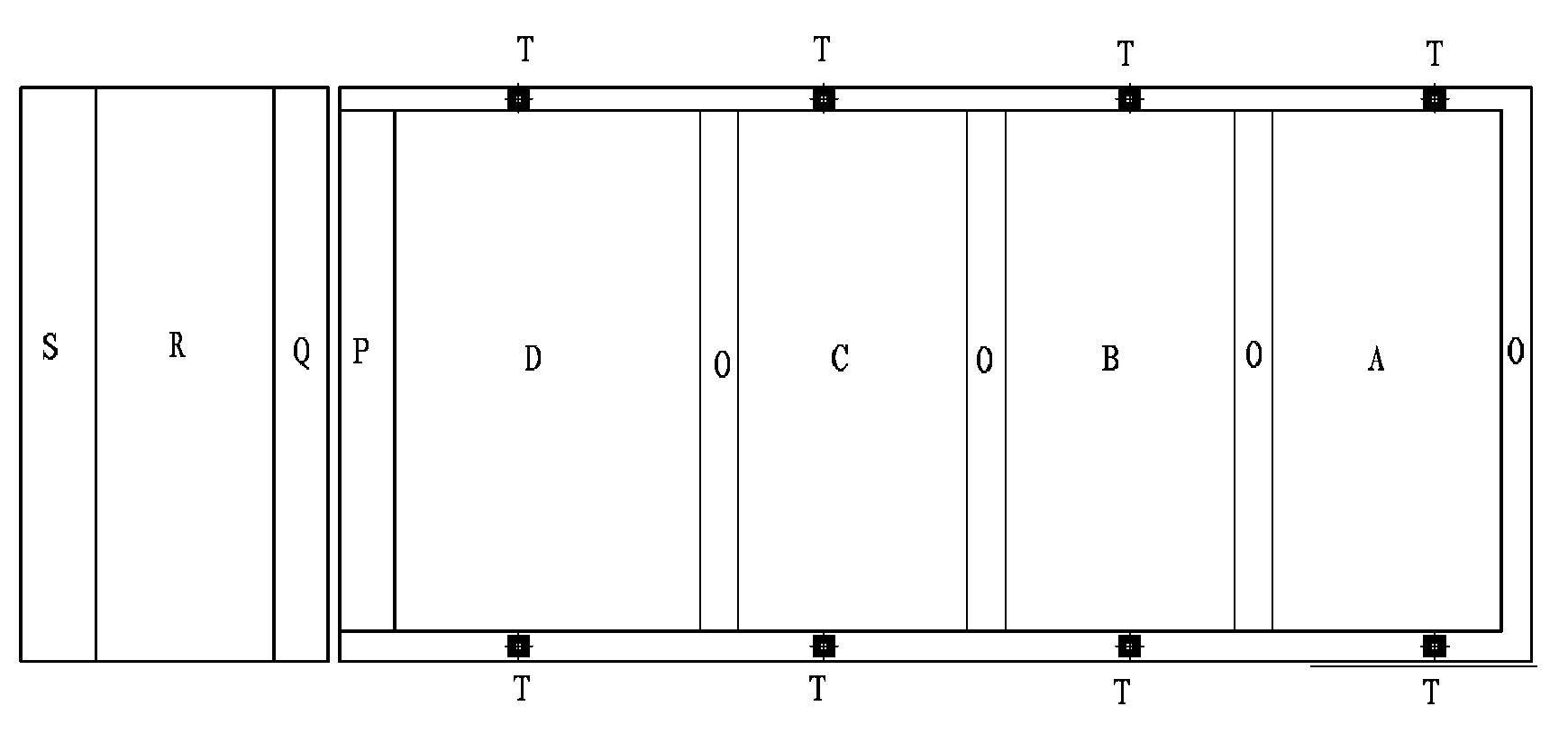

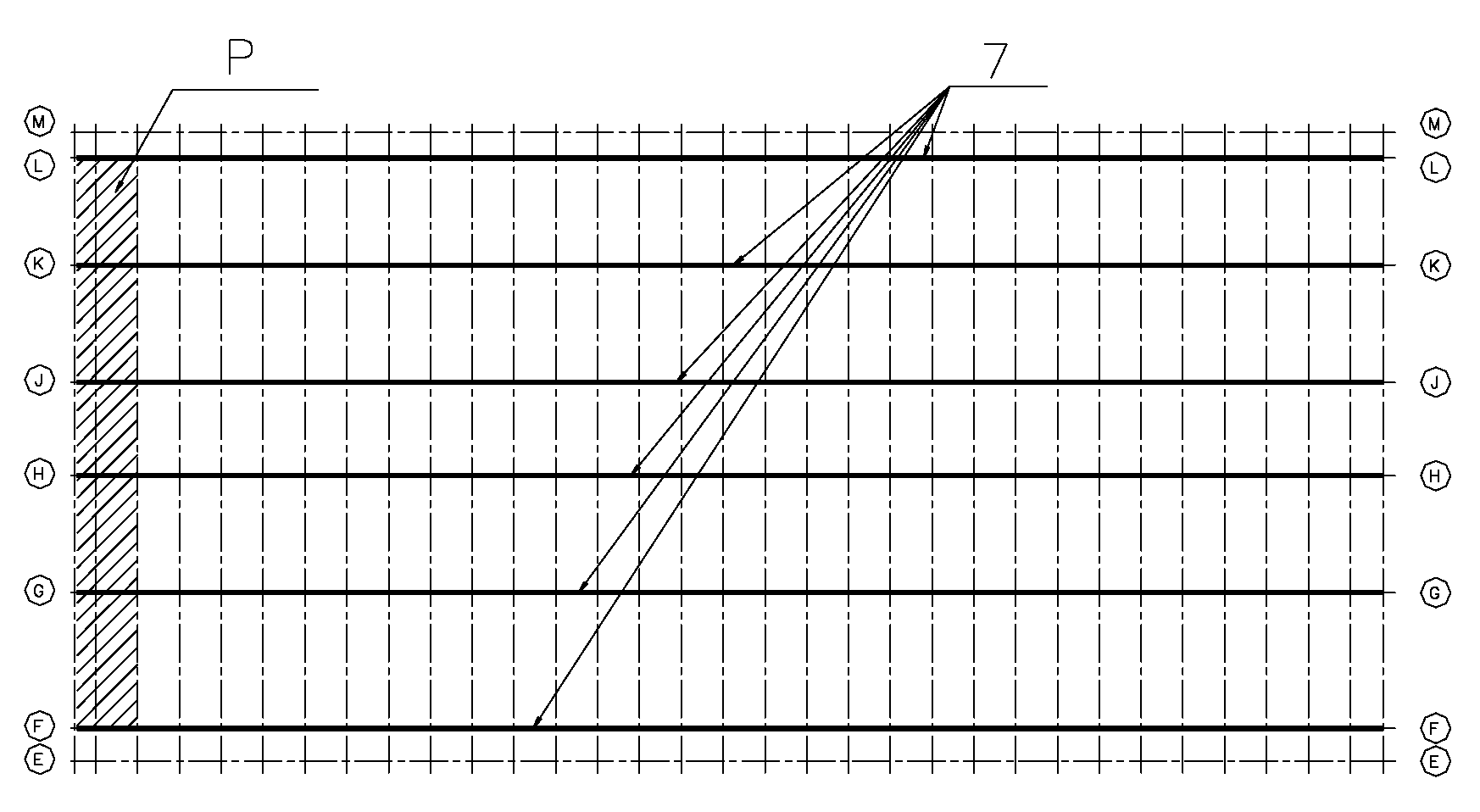

[0083] see now figure 1 with figure 2 , figure 1 It is a schematic elevation view of a steel roof truss structure according to an embodiment of the present invention, figure 2 It is the steel structure construction layout drawing of the embodiment of the present invention.

[0084] The overall sliding and unloading method of the high-cleanliness electronic factory building steel structure of the present invention is used for the high-altitude installation of the high-cleanness electronic factory building steel structure designed with a waffle plate floor, and is characterized in that it includes the following steps:

[0085] a. Determination of slip unloading technical scheme and simulation calculation of slip unloading of slip unit

[0086] In view of the construction characteristics of large-span, large-volume, high-altitude installation of the steel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com