Microwave heating device for asphalt pavement and repairing machine thereof

A heating device and asphalt pavement technology, applied in road repair, roads, roads, etc., can solve the problems of low heating efficiency, long heating time, uneven heating, etc., and achieve improved construction safety performance, good shock absorption effect, and high efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

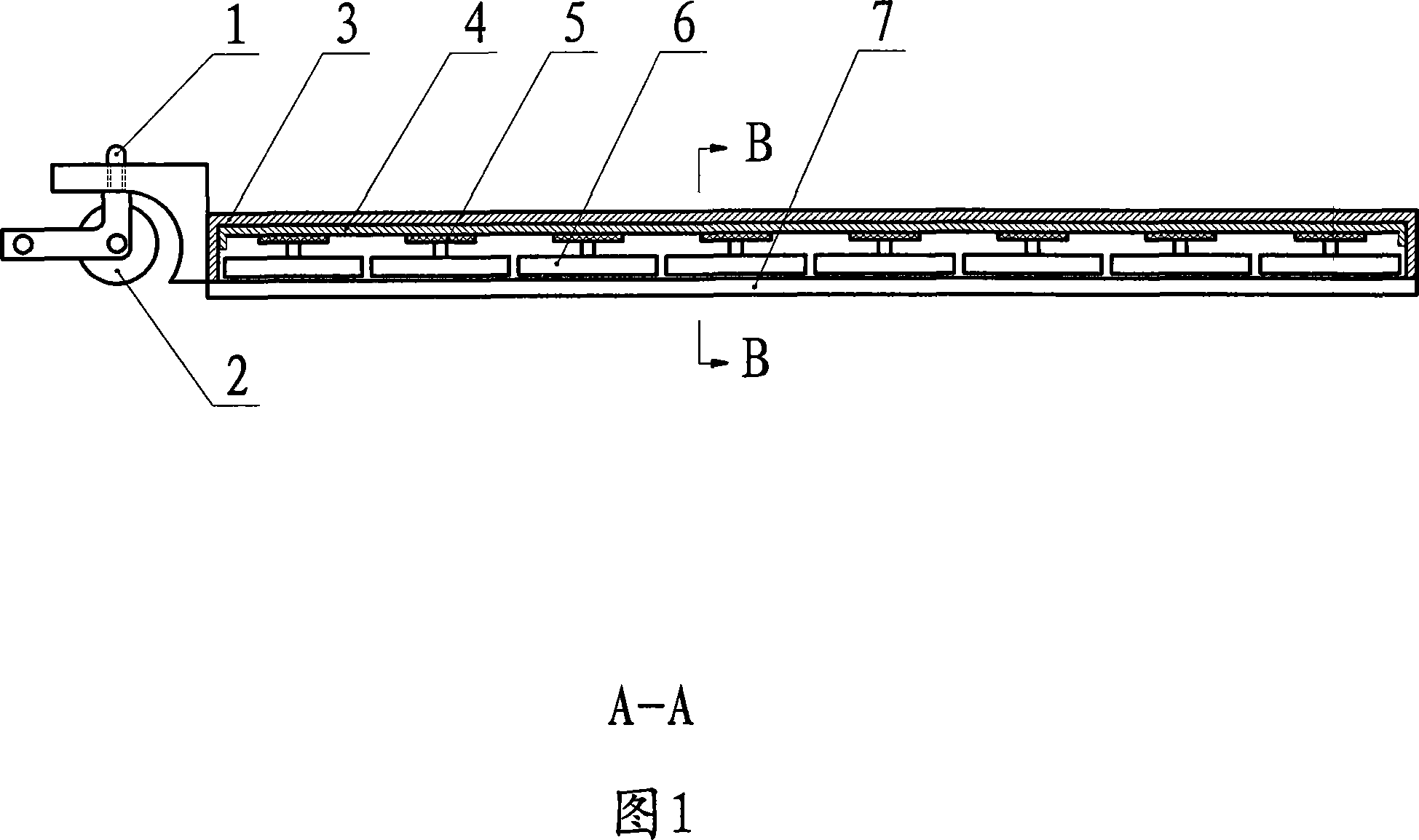

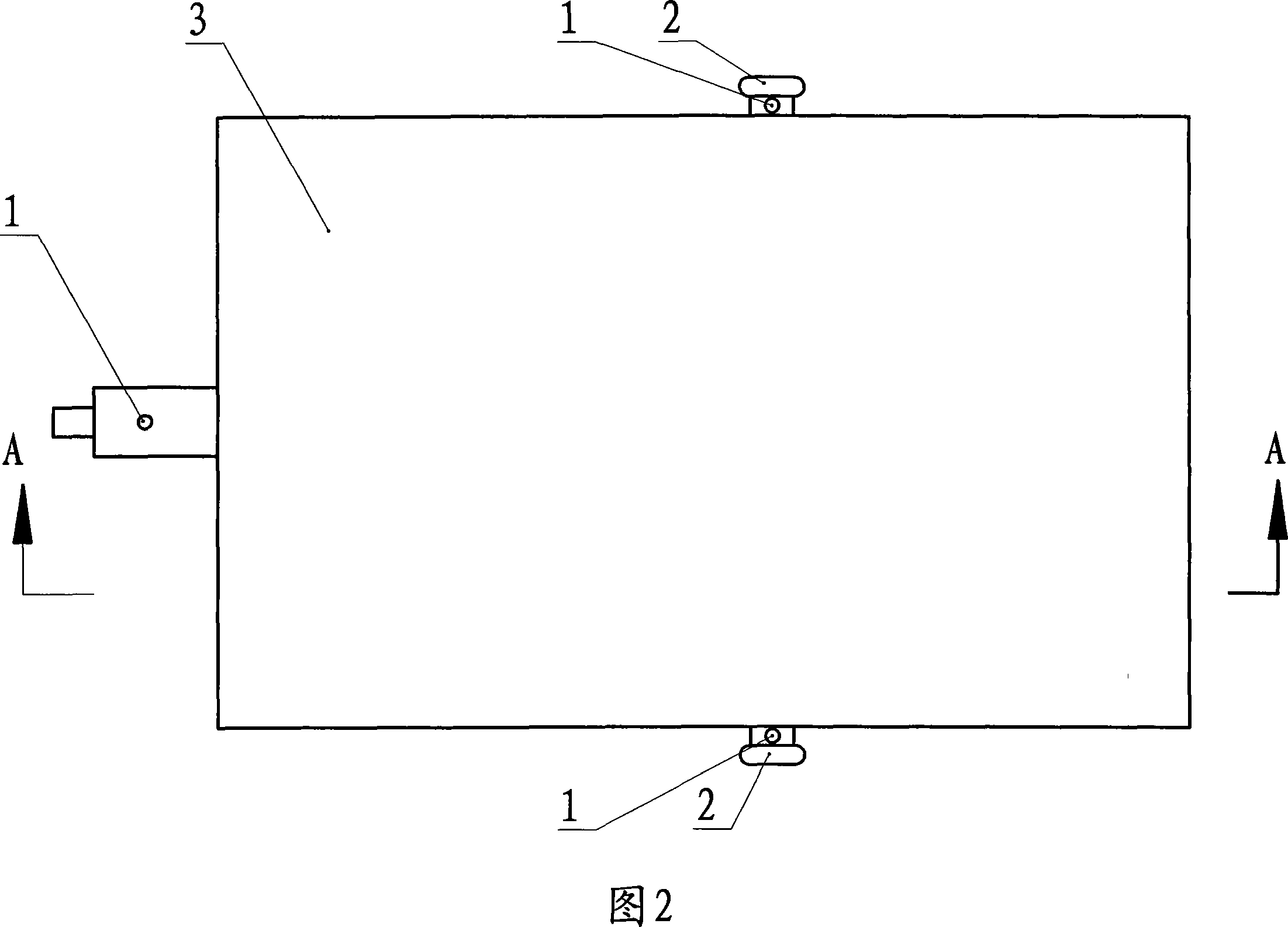

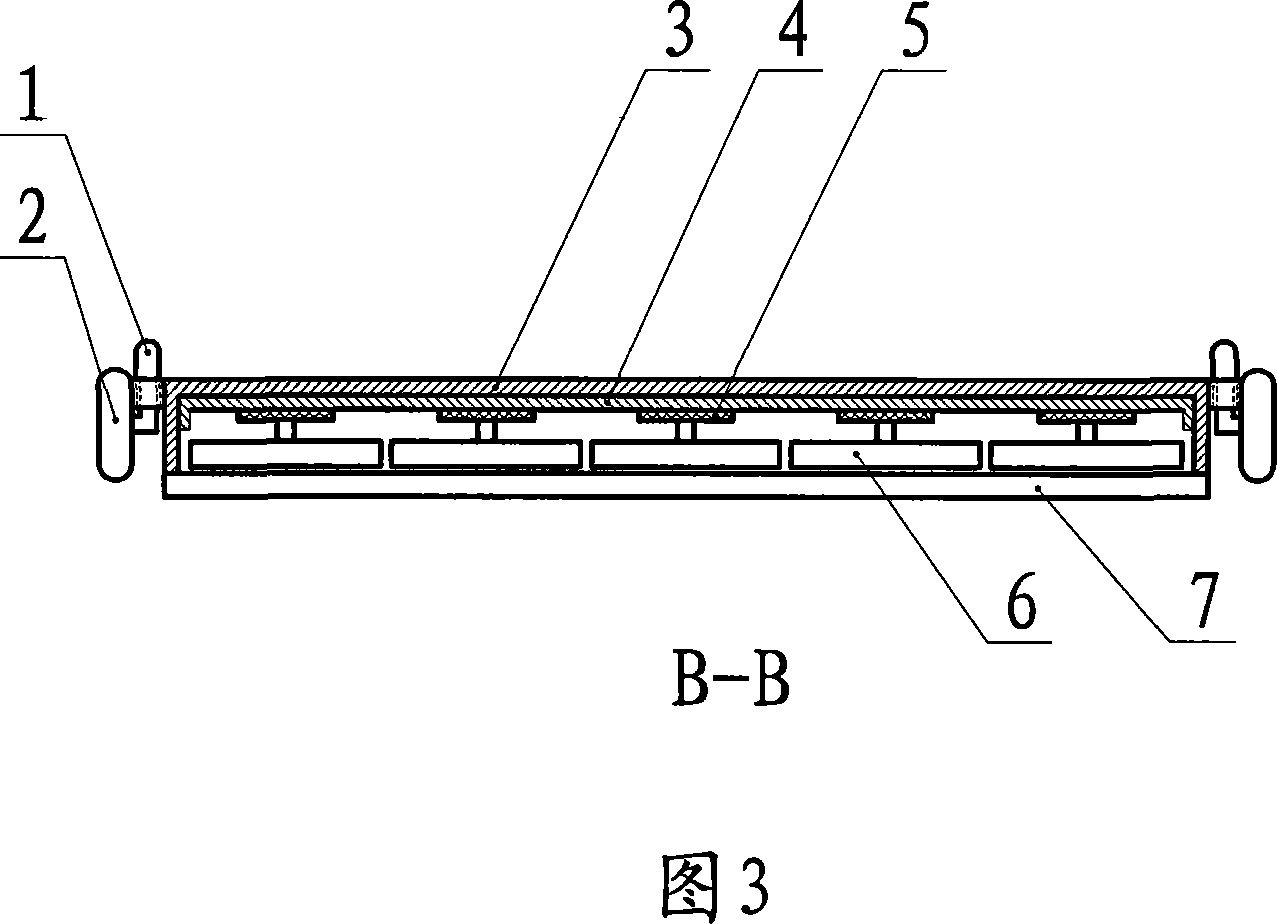

[0037] Embodiment 1: Referring to Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 5 and Fig. 7, a microwave asphalt heating device is shown in the figure. A plurality of microwave generators 6 below the frame body 4, the frame body 4 is equipped with traveling wheels 2, and the stainless steel shielding layer 3 with a certain thickness opening downwards is wrapped outside the frame body 4; The lower edge of the stainless steel shielding layer 3 close to the ground is provided with an anti-leakage enclosure 7 made of flexible material; the microwave generator 6 is installed under the frame body 4 through the rubber damping block 5, and the traveling wheel 2 and the frame body 4 are connected and installed through a hydraulic shock absorber 1; the hydraulic shock absorber 1 contains an elastic piston and a cylinder 1-1, and the cylinder 1-1 is connected with the frame body 4, The lower part of the elastic piston is connected with the walking wheel; the elastic piston contains a spring 1-4 ...

Embodiment 2

[0038] Embodiment 2: The drawings are not drawn, and Embodiment 2 is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that the flexible material for making the leak-proof enclosure 7 described in Embodiment 2 is aluminum foil Paper.

Embodiment 3

[0039] Embodiment 3: Refer to Fig. 1, Fig. 2, Fig. 3, Fig. 4, Fig. 6, and Fig. 7. Embodiment 3 is basically the same as Embodiment 1. The same symbols in the figure represent the same meaning, and the similarities will not be repeated. , the difference is that the microwave generator in the third embodiment includes a housing, a transformer, a rectifier, a magnetron microwave stirrer, and a waveguide, and the above-mentioned transformer, rectifier, and magnetron are all located on the top of the housing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com