Color base paint for wood

A basic paint and woodware technology, applied in the field of colored base paint for woodware, can solve the problems of difficult coloring, complicated process, high cost, etc., and achieve the effect of saving time and labor, ensuring uniformity and good stability in construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

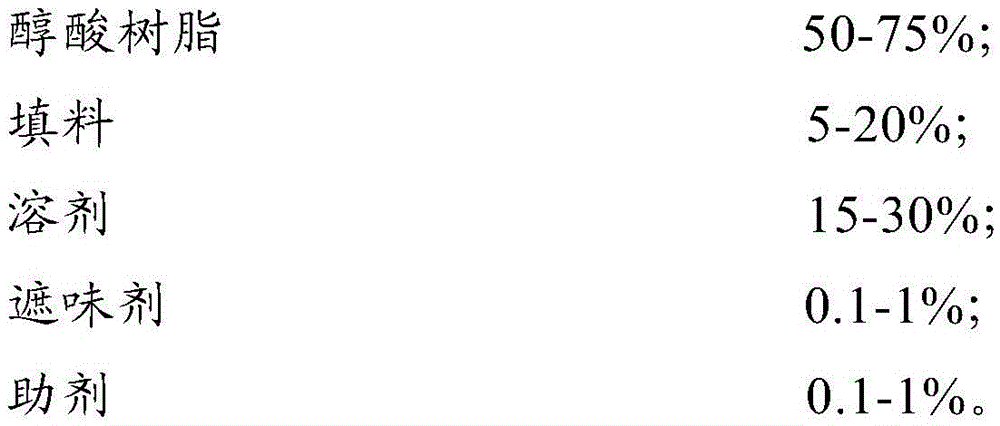

Method used

Image

Examples

Embodiment 1

[0036] The components contained in the colored base paint for wood and the weight content of each component are: alkyd resin with conjugated double bond 69.4%, filler 10%, solvent 20%, odor masking agent 0.1%, additive 0.5% .

[0037] When making the base paint according to the components and contents given in this example, it is necessary to add fillers, solvents, odor-masking agents and low-odor and low-toxicity additives to the alkyd resin, and perform high-speed dispersion, and then the base paint can be produced. paint. Adding color concentrates of various colors to the base paint produced can produce wood paints of different colors.

[0038] After the base paint is prepared according to the components and their contents provided in this example, the base paint is used to make a wood paint. The wood paint not only has heavy metal content in line with the environmental protection requirements of EU toy wood paint, and VOC content in line with the requirements of relevant ...

Embodiment 2

[0045] In the color base paint for wood, the components contained and the weight content of each component are: alkyd resin with conjugated double bond 72%, filler 5%, solvent 22.4%, odor masking agent 0.1%, additive 0.5% %.

[0046] Embodiment 2 has the advantages of Embodiment 1 above, and compared with Embodiment 1, the composition of fillers in Embodiment 2 is reduced. Correspondingly, the composition of alkyd resin is increased. Depending on the content of fillers, different color depths can be produced. High-quality wood paint, less filler, easy to color base paint, can be used to make dark wood paint; more fillers, can be used to make light-color wood paint.

[0047] The color base paint for woodware provided by the invention is used in conjunction with color concentrates of various colors to produce woodware paints of different colors, such as:

[0048] 1) When making teak wood paint, the weight ratio can be:

[0049] Base paint: yellow color essence: red color essen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com