Assembling integrated type window frame for steel structure, and construction method of assembling integrated type window frame

A construction method and integrated technology, applied to the base frame and other directions, can solve the problems of unsatisfactory use effect of plastic steel window (door) frame, complicated construction and installation, long construction period, etc., to achieve easy production and construction, improve construction quality, The effect of saving time and effort in construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

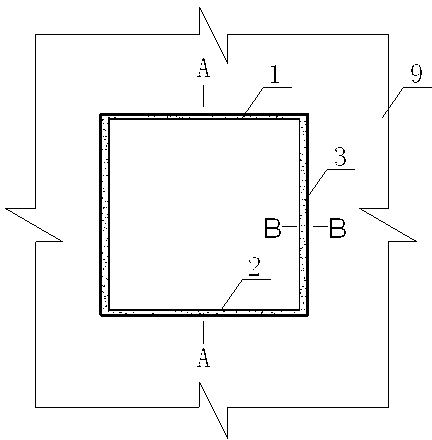

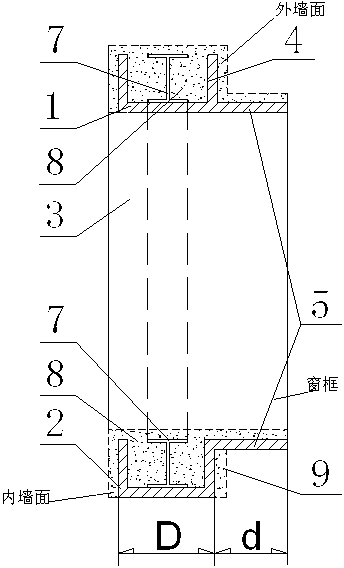

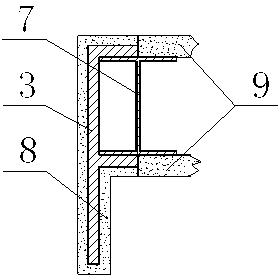

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as a basis for any limitation of the present invention.

[0025] Embodiments of the present invention: a construction method for an assembled integral window frame for a steel structure of the present invention, which uses steel wire mesh and cement mortar as raw materials in the factory in advance, adopts a traditional mold casting method, and mass-produces the assembled window frame. The components of the integral window frame, at the same time, make a card groove on the outer side of each component of the assembled integral window frame, and then transport the assembled integral window frame to the industrial or civil building that has completed the steel structure construction site, the steel structure is also a spatial steel grid box structure (such as Figure 7 shown); according to the needs of use, the opening of the steel grid fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com