Membrane panel structure being easy to exhaust and convenient to glue

A convenient, thin-film technology, applied in electrical components, electrical switches, circuits, etc., can solve the problems of time-consuming and labor-intensive lamination of thin-film panels, poor effect, etc., and achieve the effect of avoiding foaming, outstanding effect, and time-saving and labor-saving construction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

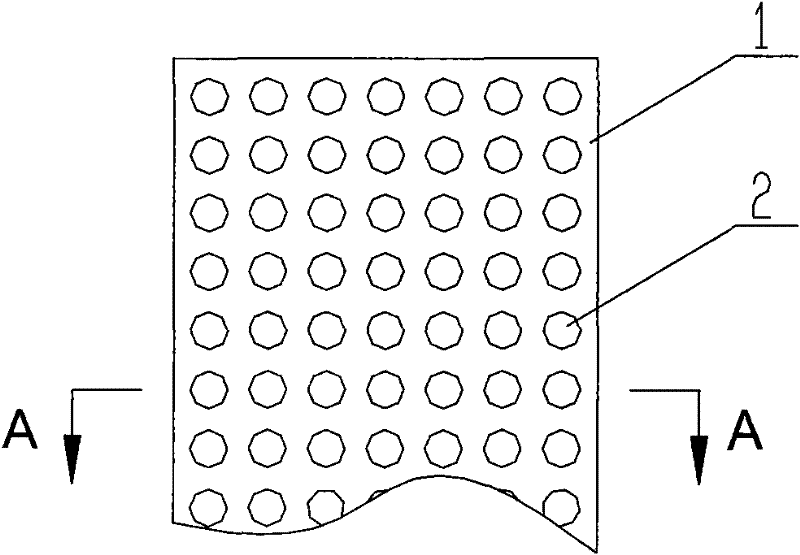

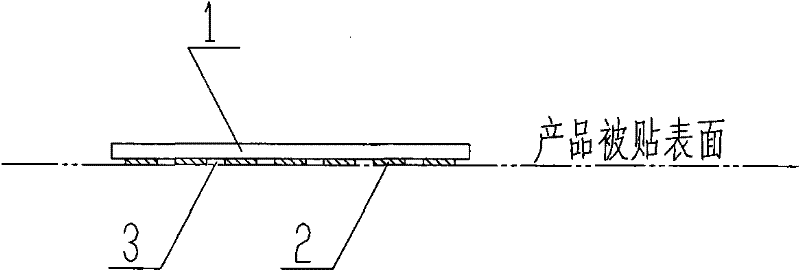

[0017] Such as figure 1 and figure 2 As shown, a specific embodiment of the structure of the present invention is provided. On the back bonding surface of the film panel 1, there are a plurality of protruding platform-shaped adhesive layers 2 made of adhesive that are not connected to each other. These protrusions are circular in shape and arranged uniformly. During construction and lamination, the gaps 3 between the protrusions become exhaust passages during lamination, and the film panel 1 is bonded to the surface of the product to be pasted by glue.

Embodiment 2

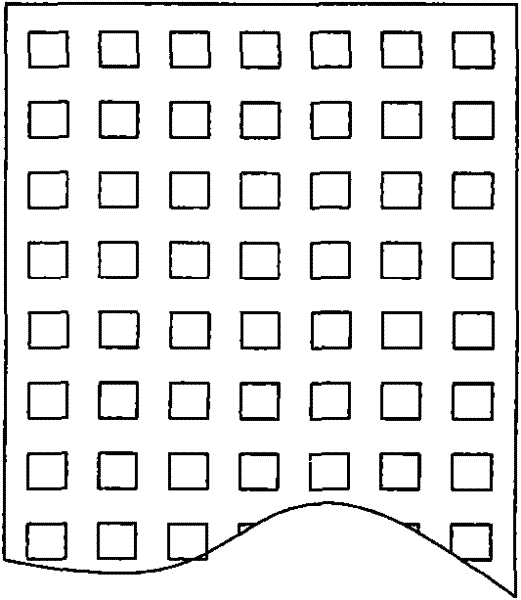

[0019] Such as image 3 As shown, another specific embodiment adopting the structure of the present invention is provided, and the shape of the protrusions used in it is square and arranged in a uniform shape.

Embodiment 3

[0021] Such as Figure 4 As shown, another specific embodiment using the structure of the present invention is given, and the shape of the protrusions used in it is a mixture of square and circular, and is uniformly arranged.

[0022] In addition to the protrusion shapes described in the above several embodiments, the present invention can also adopt a variety of protrusion shapes, such as polygons, triangles, etc., or their mixture. The common feature is that between these protrusions Leave a proper gap, the size of the gap and the height of the protrusion can be determined according to the thickness of the film panel and the width of the web, so that it can not only achieve the best exhaust effect, but also meet the requirements of bonding strength.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com