Contracting device for whole steel platform corner external scaffold system and construction method

A kind of integral steel and scaffolding technology, which is applied to the accessories of scaffolding, scaffolding supported by house structure, and house structure support, etc. It can solve the problems of speeding up the construction period and the inability to collect points at the corner of the integral steel platform corner at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

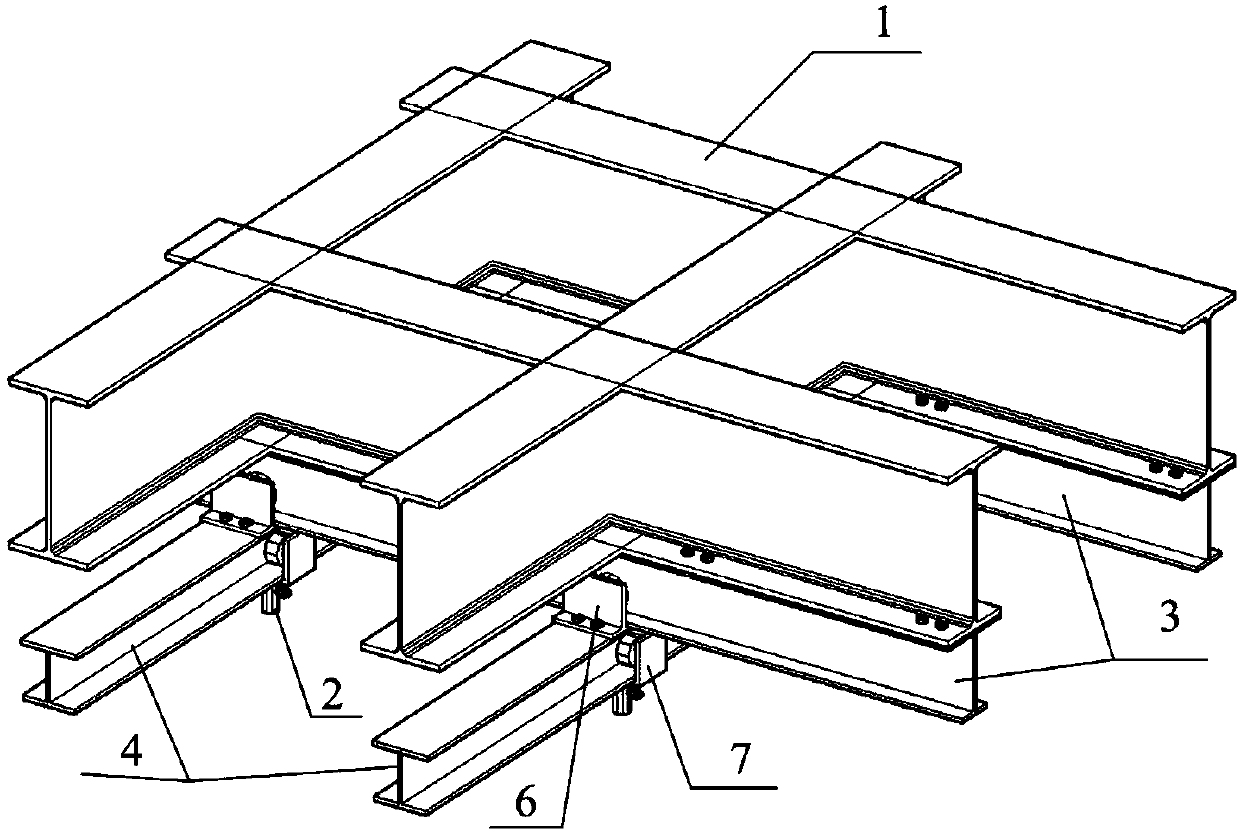

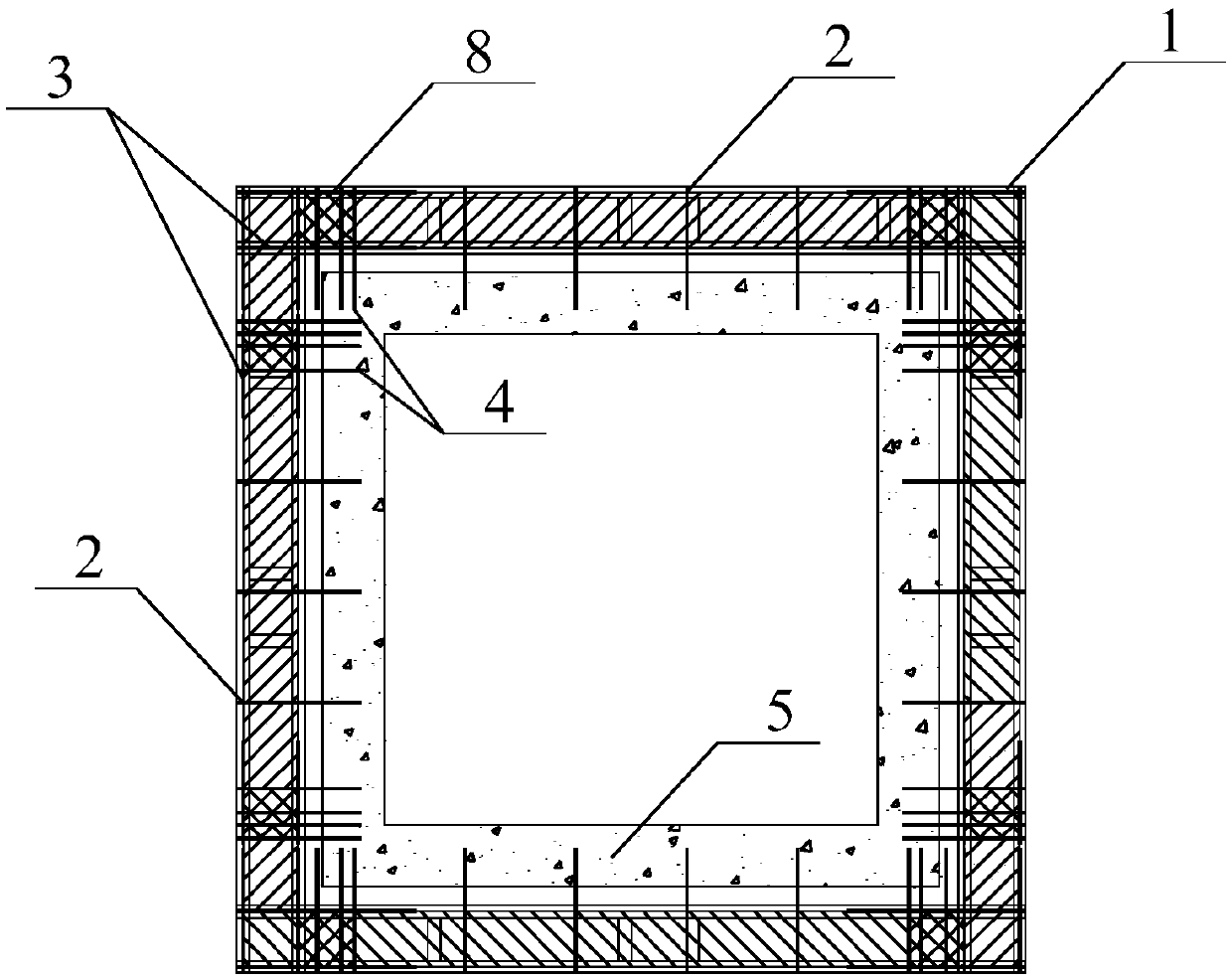

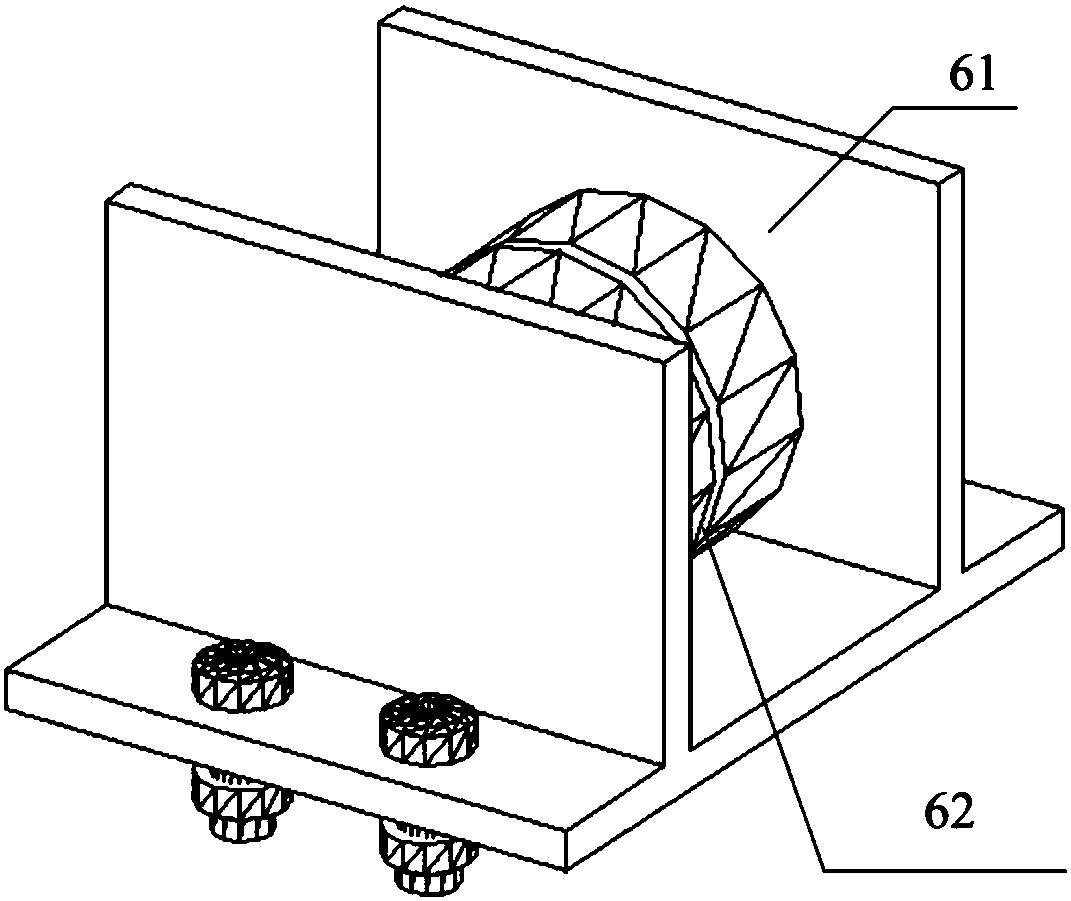

[0037] Combine below Figure 1 to Figure 9 Describe in detail the structural composition of the collection and distribution device of the external scaffolding system at the corner of the integral steel platform of the present invention.

[0038] Such as Figure 1 to Figure 9As shown, this embodiment discloses a collection and distribution device for the external scaffolding system at the corner of the integral steel platform. The retracting device includes a translating guide rail beam group and an adduction guide rail beam group arranged in an orthogonal superposition, the translation guide rail beam group is a pair of translation guide rail beams 3 arranged in parallel, and the adduction guide rail beam group is a pair of adduction guide rail beams arranged in parallel. Guide rail beam 4; the upper translation guide rail beam group is fastened to the lower flange of the steel girder 1 at the corner of the integral steel platform, and the lower retraction guide rail beam gro...

Embodiment 2

[0048] Please continue to refer Figure 1 to Figure 9 , the present embodiment provides a construction method of a harvesting device for an external scaffolding system at the corner of an integral steel platform, taking the three-way two-way harvesting and dividing as an example. Wherein the aisle plate comprises a first aisle plate 81, a second aisle plate 82 and a third aisle plate 83, and the external scaffolding comprises a first external scaffolding 21, a second external scaffolding 22 and a third external scaffolding 23, The side nets include a first side net (not shown), a second side net (not shown) and a third side net (not shown). One side net. This construction method comprises the steps:

[0049] Step 1. Cooperate and arrange two sets of collection and distribution devices on both sides of the four corners X and Y of the overall steel platform, and correspondingly lay a number of split walkway slab modules (that is, the first walkway slab 81, the second walkway s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com