Repairing method and structure for building wall crack

A technology for building walls and cracks, which is applied to the field of repairing building wall cracks, can solve the problems that the repairing method of building wall cracks is not ideal, affect the appearance and function of buildings, and show wall cracks, etc. Construction saves time and effort and reduces the effect of continued deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

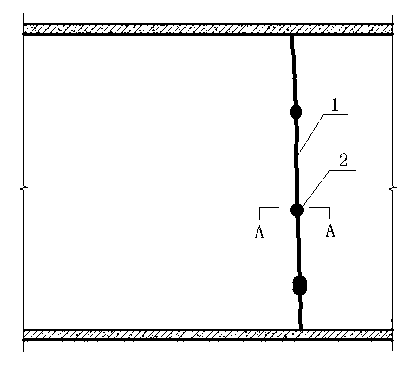

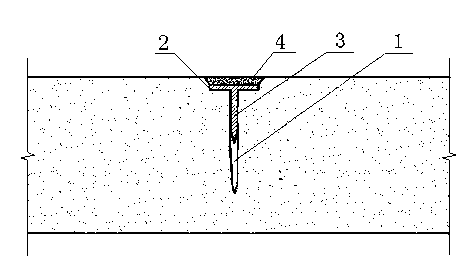

[0014] Embodiment of the present invention: when repairing the cracks of the load-bearing wall and non-load-bearing wall in the existing brick-concrete, frame, shear wall, frame shear wall structure, a kind of building wall of the present invention can be used The method of repairing the cracks in the building body includes the method of using traditional cement mortar or putty powder to seal and fill up the cracks in the building wall. Grind grooves 2 on the crack 1 along the length direction of the crack 1 at an interval of ~20cm, and then insert a metal nail 3 into the crack 1 in each groove 2, and insert a metal nail 3 into the crack 1 prevent and reduce the deformation of the crack 1, and then cover the nail cap end of the metal nail 3 with cement mortar 4 and fill the groove 2. After the cement mortar 4 is finally set, the cement mortar or Pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com