Indoor wall stone cladding

A technology for dry hanging of stone and inner wall, applied in covering/lining, construction, building structure, etc., can solve the problems of many materials, complex structure, large distance between stone and wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

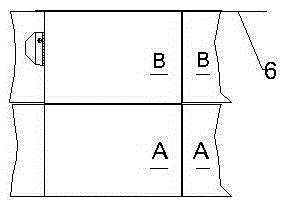

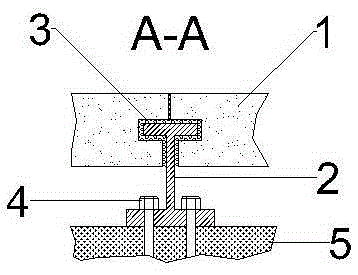

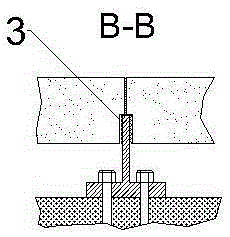

[0008] In the figure, 1. Stone board, 2. "I" steel frame, 3. Dry hanging glue, 4. Expansion screw, 5. Wall surface, 6. Top corner of wall surface, "I" steel frame 2 is arranged vertically , fixed on the wall 5 with expansion screws 4, the distance between the centerlines of the two "I"-shaped steel frames 2 is 1 mm longer than the length of the stone plate 1, and the "I"-shaped steel frames 2 are placed on top (6 places at the top corners of the wall) The upper edge above the vertical support removes a section that is 2 mm longer than the height of the stone plate 1, and the left and right sides of the stone plate 1 are pre-cut grooves corresponding to the upper edge of the "I" character steel frame 2. The upper edge of the steel frame 2 is 2 mm larger, and the inner groove platform of the stone plate 1 (the back side of the stone 1) is cut off by 2 mm to leave a space for the vertical support below the upper edge of the "I"-shaped steel frame 2. When installing, Hang the ston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com