Mounting tool for coke oven sleeve and application of mounting tool for coke oven sleeve

A technology for installing tools and casings, which is applied to coke ovens, coke oven heating, coke oven parts and other directions, can solve the problems of installation accuracy and speed being difficult to control, inconvenient installation of coke oven casings, etc. Easy to make and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

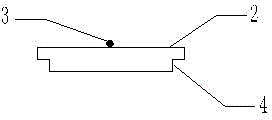

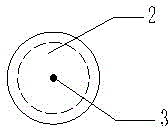

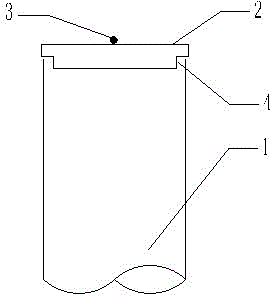

[0023] see now figure 1 and figure 2 , figure 1 It is a schematic diagram of the structure of the adjustment plate according to the embodiment of the present invention, figure 2 It is a top view of the adjustment disc of the embodiment of the present invention. As shown in the figure, the adjustment disc 2 is a circular boss made of steel plate, the surrounding of the adjustment disc is smooth and smooth, its thickness is 8mm, and its diameter is the same as the outer diameter of the casing to be installed; the circular boss The bottom of the piece is a circular boss with steps 4, the circular boss and the circular boss are concentrically arranged, the diameter of the circular boss is 3mm smaller than the inner diameter of the pre-installed casing, and the height of the circular boss is be 4mm so that the circular boss of the circular boss part is placed in the casing 1, image 3 It is a schematic diagram of the combination of the adjustment plate and the steel sleeve in...

Embodiment 2

[0026] The application of a coke oven sleeve installation tool in the installation of coke oven sleeves.

[0027] Figure 4 It is a schematic diagram of the use state of the adjustment disc in the embodiment of the present invention. Coke oven bushing installation tool of the present invention, the application steps of adjusting disc 2 in coke oven bushing installation are as follows:

[0028] (1) Make the horizontal 0.3mm steel wire 5 align with the center alignment point 3 of the adjustment disc, so that the casing in the X-axis direction is aligned.

[0029] (2) Fix one section of the steel ruler 6 on the middle channel steel 8, so that the scale line coincides with the longitudinal center of the coke oven, and fix the other end on the flue fixing frame, so that the steel ruler is naturally straightened and aligned with the horizontal 0.3mm steel wire 5 is flush and placed on the top of the adjustment plate 2, and then manually adjust the sleeve 1 left and right so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com