Indoor wall surface stone dry installation method

A technology for interior walls and stone slabs, applied in covering/lining, construction, building construction, etc., can solve the problems of complex structure, cumbersome process, and many materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

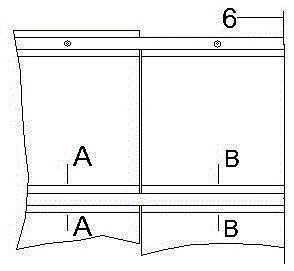

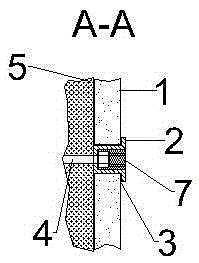

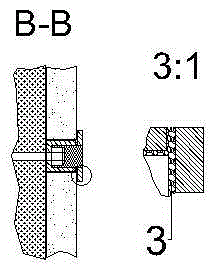

[0008] In the picture, 1. Stone slab, 2. Flanging channel steel, 3. Dry hanging glue, 4. Expansion screw, 5. Wall surface, 6. The other end of the wall surface, 7. Caulking cement, the channel steel edge has a direction The edge of the eversion, namely: the flanged channel steel 2, the flanged channel steel 2 is discharged horizontally, there are expansion screws 4 in the groove to fix the flanged channel steel 2 on the wall 5, and the two flanged channel steels 2 correspond to vertical supports The spacing is 2 mm larger than the height of the stone slab 1, and the distance between the flanging channel 2 and the wall 5 is 1 mm larger than the thickness of the stone slab 1. When installing, install a single flanging channel 2 from the wall 5 The upper and lower rows are fixed horizontally on the wall 5, and the place where the stone slab 1 is placed is smeared with dry hanging glue 3, and then the stone slab 1 is installed into two flanged channel steel 2 on the opposite upper e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com