Process method for insulation attaching type bonding of large-scale motor rotor magnetic pole body

A rotor magnetic pole and pole body insulation technology, applied in the direction of laying solid insulation, etc., can solve the problems affecting the stability of the magnetic pole insulation performance, the breakdown of the insulation of the pole pole body, the breakdown of the pole core, etc., so as to prevent glue coating Unevenness, guaranteed bonding quality, uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

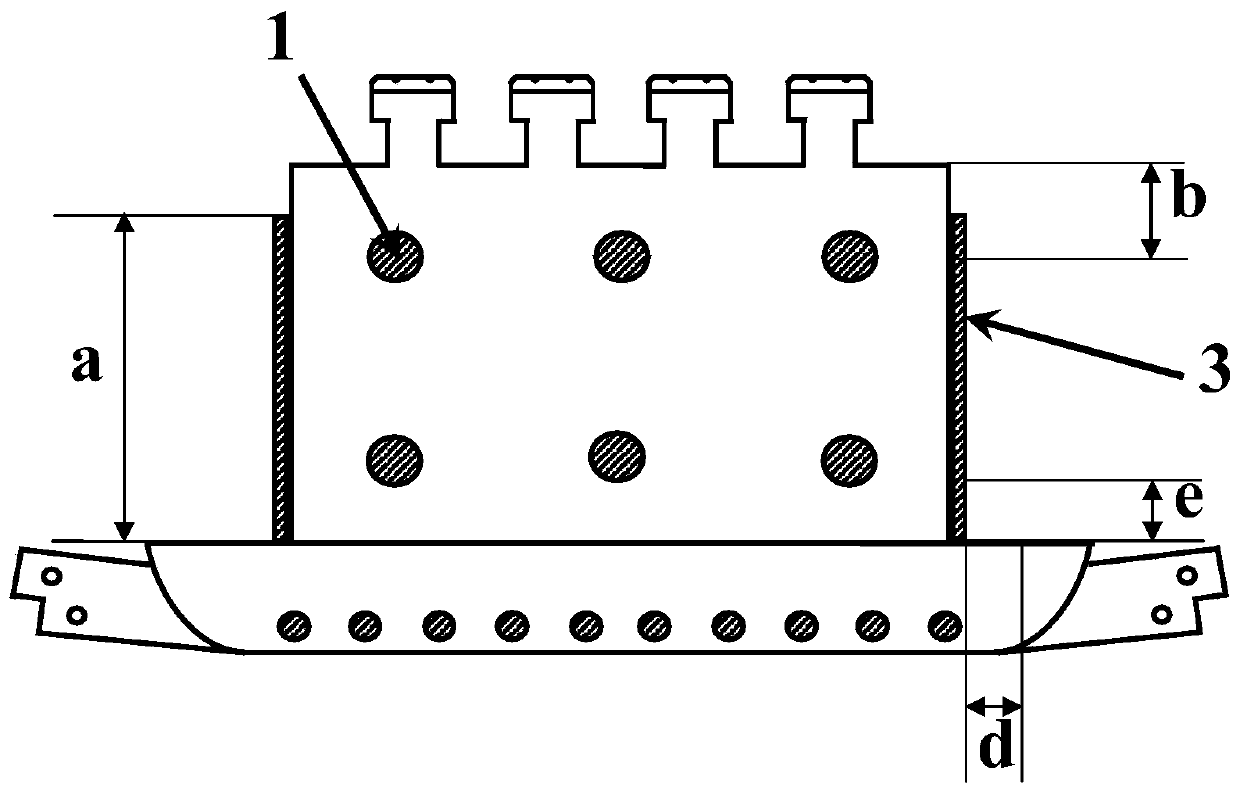

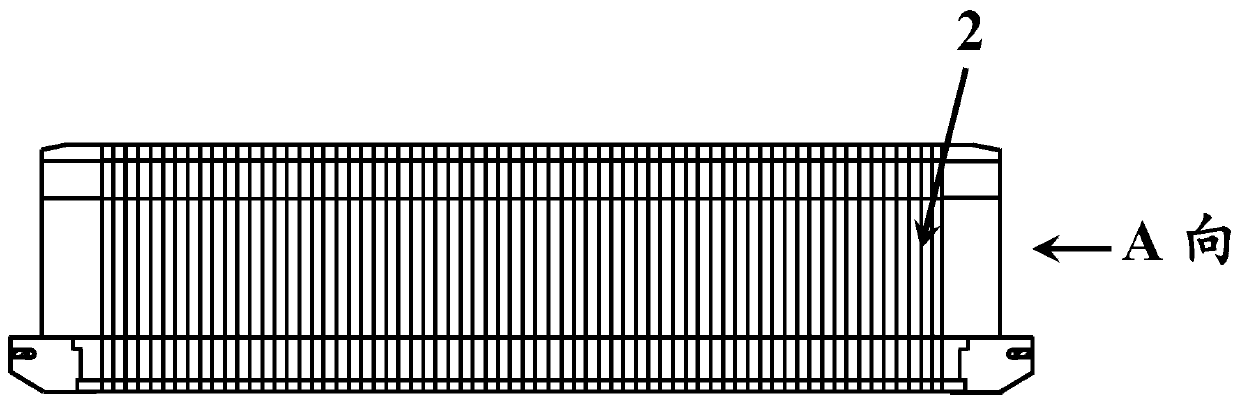

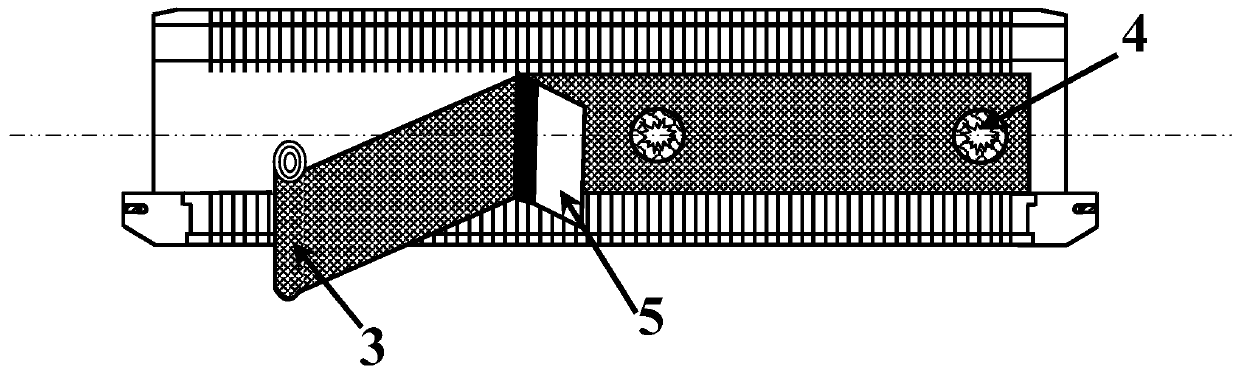

[0032] The purpose of the present invention is to provide a process method for insulating and attaching the magnetic pole body of the rotor of a large motor. The implementation of the present invention comprises the following process steps:

[0033] 1) Measurement of the flatness of the rotor pole core: Use a ruler and a feeler gauge to measure the flatness of the rotor pole core. The measurement standard is that the waviness in the range of 100 mm is less than 0.50 mm. The wooden side corrects its torsion;

[0034] 2) Cleaning of the rotor pole core: Use a square iron to remove the welding beans on the surface of the pole core, polish and polish the pole core with a polishing machine, clean up the burrs and oxide film, use a vacuum cleaner to clean the powder from the pole core grinding, and wipe it with cotton gauze dipped in alcohol Remove grease and dust on it;

[0035] 3) Ultra-flat treatment of the insulating and bonding parts of the rotor magnetic pole, iron core and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Unilateral width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com