Steel tube straightening machine

A technology for straightening machines and steel pipes, applied in the field of steel pipe straightening machines, which can solve the problems of steel pipe surface leveling machine damage, easy jamming, and difficult straightening work of straightening machines, so as to achieve fast straightening speed and avoid pipe jamming , Improve the effect of straightening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

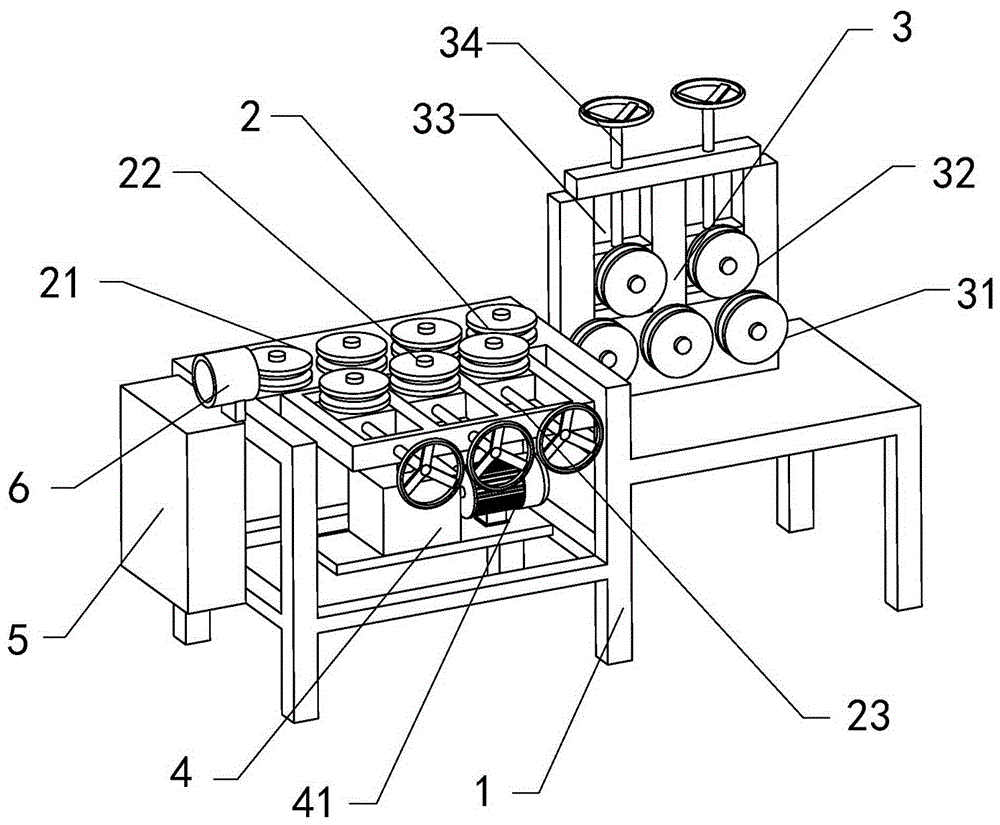

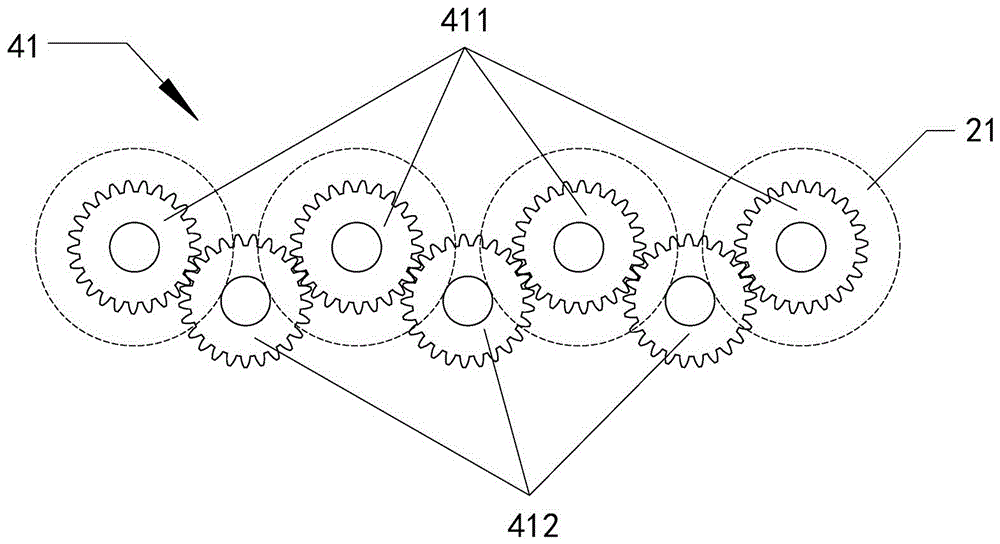

[0024] according to Figure 1 ~ Figure 2 As shown, a steel pipe straightening machine includes a frame 1, wherein the frame 1 is provided with an end-to-end transverse straightening zone 2 and a longitudinal straightening zone 3 as well as a driving device 4 for driving and a driving device for controlling The control box 5 controls the driving device 4 to drive the transverse straightening zone 2 and the longitudinal straightening zone 3 to work.

[0025] Horizontal straightening zone 2 comprises, some horizontal fixed wheels 21 that are arranged horizontally, some horizontal sliding wheels 22 and some horizontal slideways 23 that are used for horizontal sliding wheel 22 sliding by sliding adjustment and horizontal fixed wheel 21 spacing; 3 comprises, vertically arranged several longitudinal fixed wheels 31, several longitudinal sliding wheels 32 which are adjusted by sliding to space with the longitudinal fixed wheels 31, and some longitudinal slides 33 for the longitudinal ...

Embodiment 2

[0035] The difference from the above-mentioned embodiment 1 is that the outer sides of the horizontal fixed wheel 21, the horizontal sliding wheel 22, the longitudinal fixed wheel 31 and the longitudinal sliding wheel 32 are all provided with a protective layer for protecting the steel pipe, and the protective layer adopts a polytetrafluoroethylene layer, rubber layer, resin layer or plastic layer, which can effectively protect the surface of the steel pipe from being damaged during the straightening process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com