The control method of changing the type of winding machine with large yarn storehouse

A control method and winder technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve the problems of heavy manual operation workload, tube jamming, low efficiency, etc., and reduce labor intensity, Avoid the effect of stuck pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

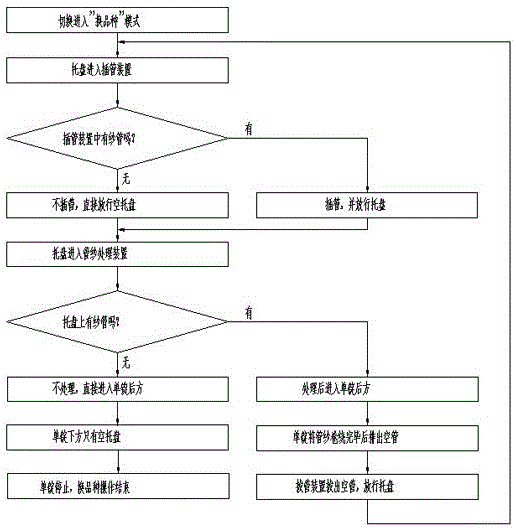

[0023] see figure 1 , an embodiment of the control method for the type change operation of a large yarn warehouse type winder of the present invention, when the winder changes type, the controller switches the working mode to the "change type" operation mode.

[0024] The control method in the operation mode of "changing varieties" is as follows:

[0025] 1. When the tray runs to the intubation device, check whether there is a bobbin in the intubation device. If there is a bobbin, release it after intubation. If there is no bobbin, do not perform the intubation operation, and release the empty tray directly;

[0026] 2. The released pallet continues to run to the bobbin processing device. At this time, it is detected whether there is a bobbin on the pallet. If there is a bobbin, it will enter the rear of the single spindle after processing. If there is no bobbin, it w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com