Patents

Literature

37results about How to "Achieve the purpose of transportation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

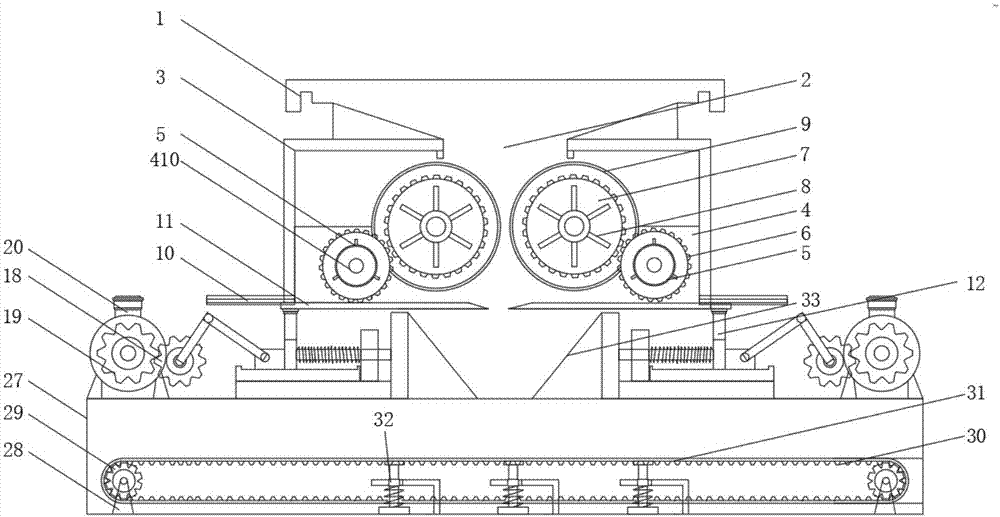

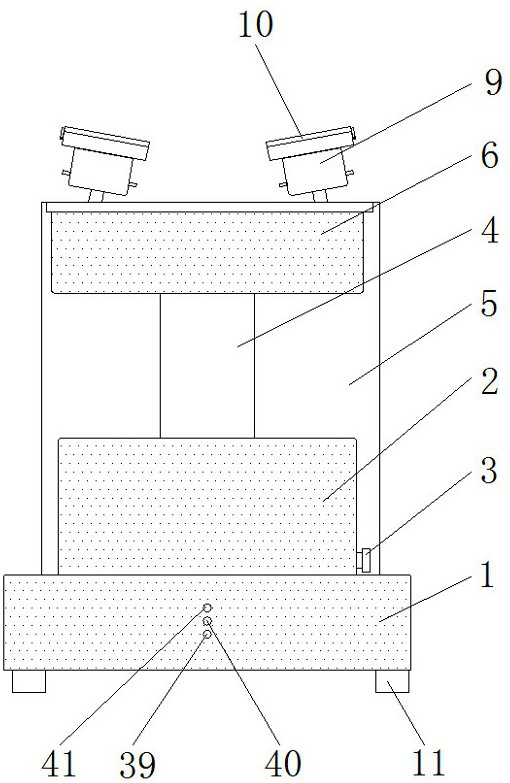

Steel ball polishing and transporting device

ActiveCN107877348AAchieve the purpose of polishingAchieve work uniformityPolishing machinesGrinding drivesGear wheelSteel ball

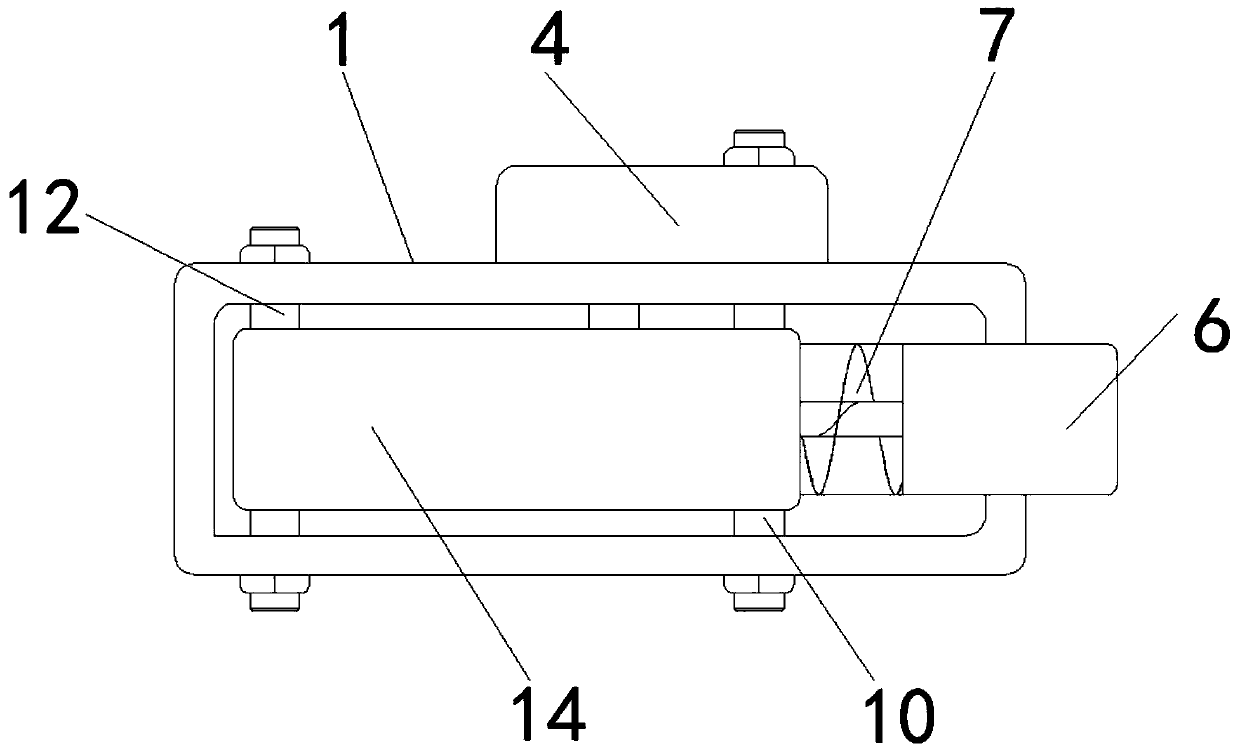

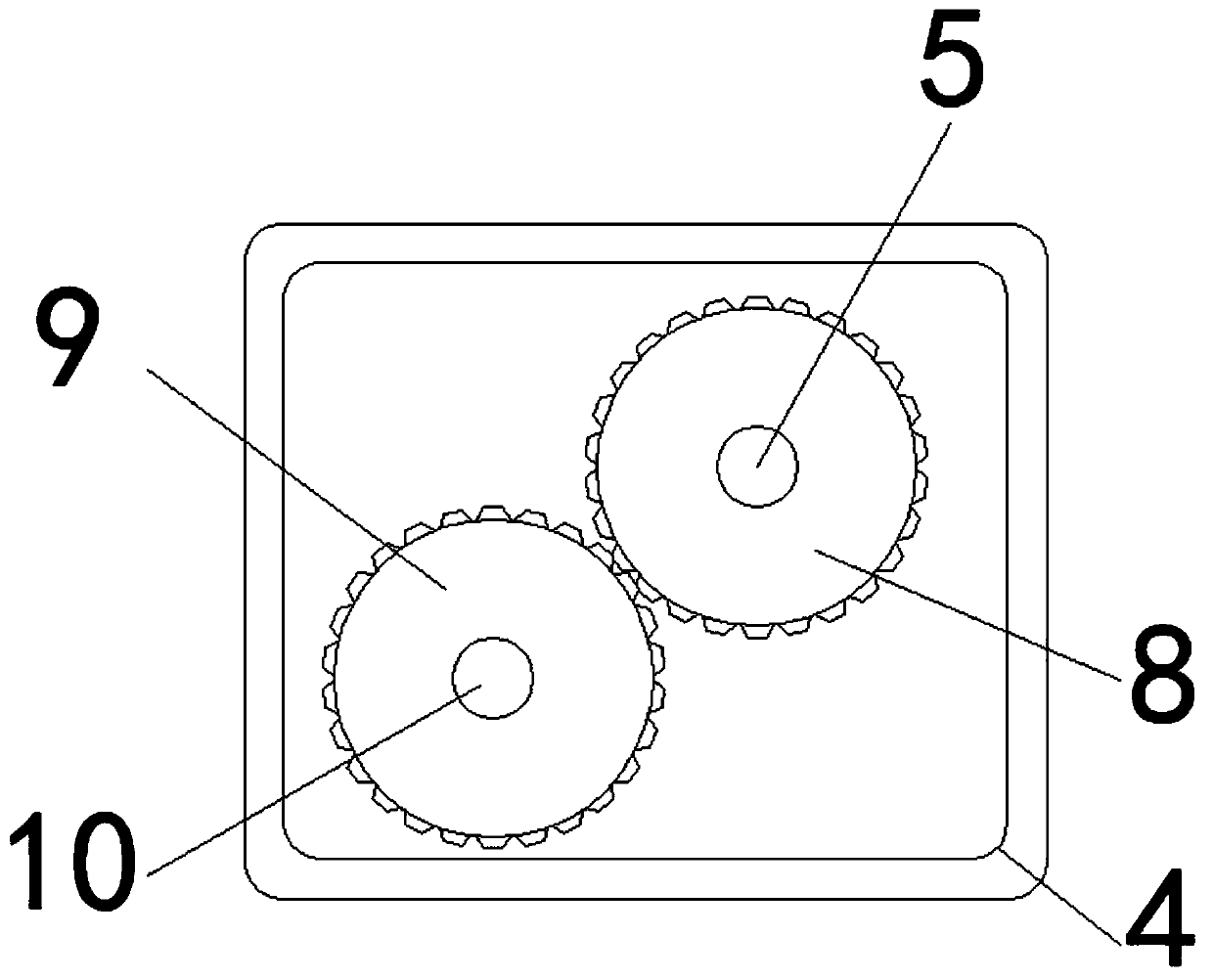

The invention discloses a steel ball polishing and transporting device, which comprises a feeding top cover. A feeding inlet is formed in the bottom part of the feeding top cover; a polishing work boxis fixedly connected to the bottom part of the feeding top cover; power devices are fixedly connected to two sides of the bottom part of an inner wall of the polishing work box and are fixedly connected with power rotating wheels; each power rotating wheel is rotatably connected with a first gear through an output shaft; each first gear is located on the upper part of the inner side of the polishing work box and is engaged with a second gear; each second gear is rotatably connected with a polishing roller wheel through a rotary shaft; and a detachable fixing handle is arranged on the surfaceof each second gear. The invention relates to the technical field of steel ball polishing transporters. The steel ball polishing and transporting device can be used for polishing, discharging and transporting steel balls, the stability of the rotating speed and the working evenness are ensured, the polishing quality and the polishing efficiency are ensured, the possible problems occurred during work are reduced, the transportation efficiency is ensured, and the automatic process is improved.

Owner:临沂临港经济开发区合顺物流有限公司

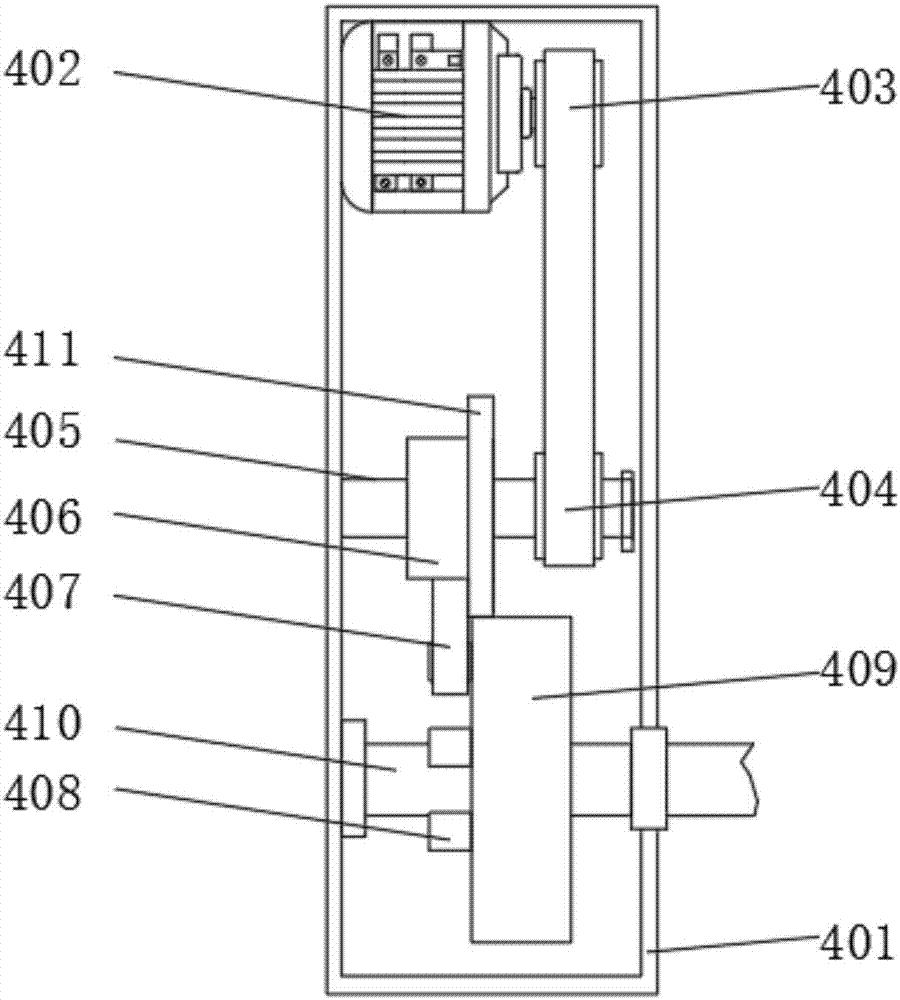

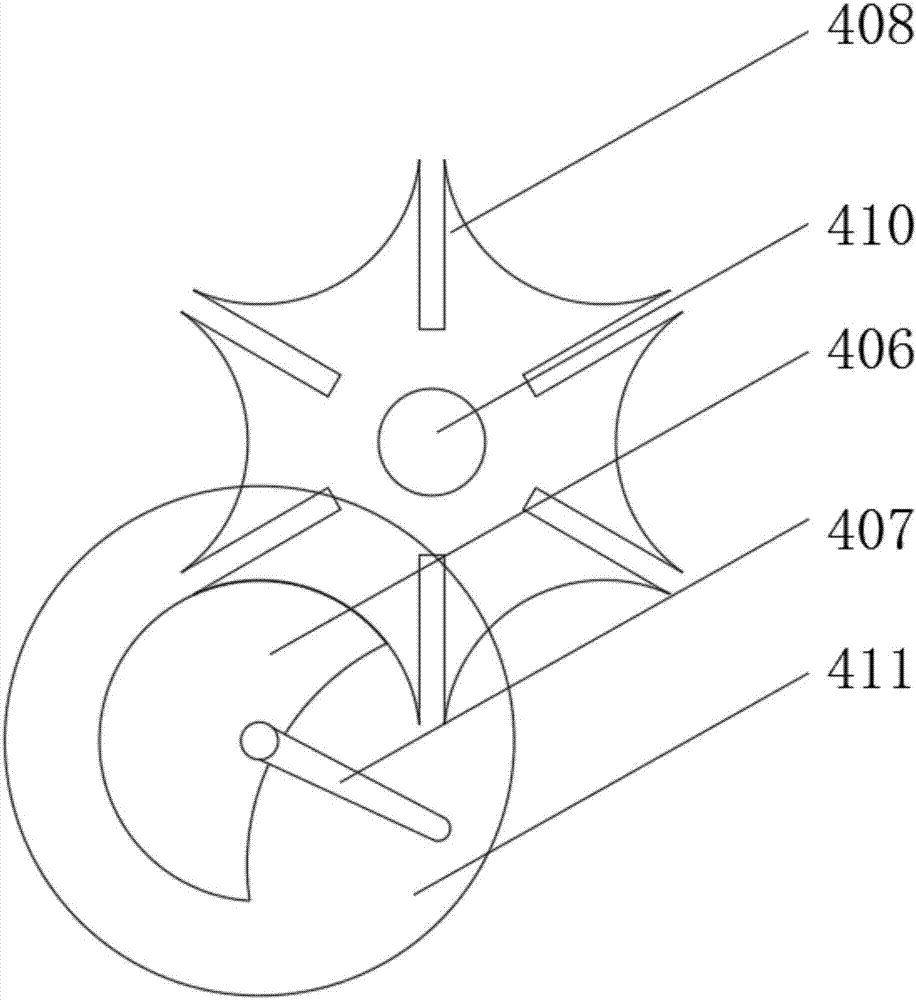

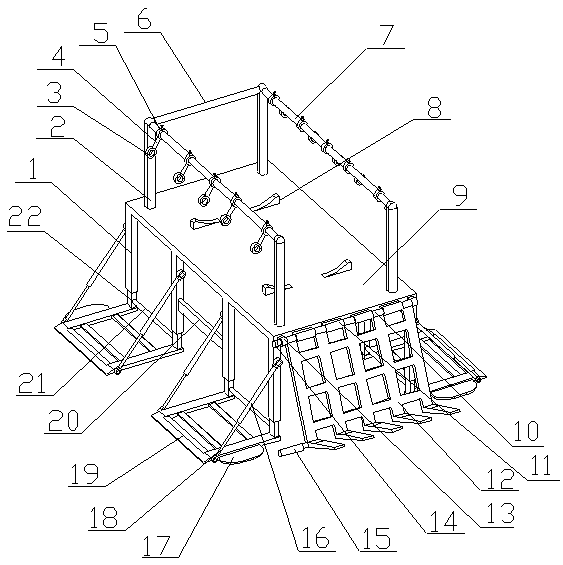

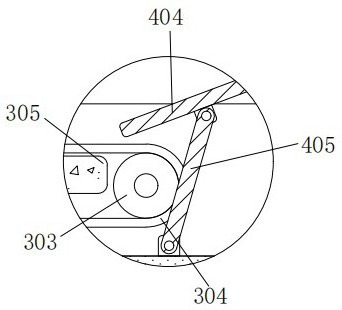

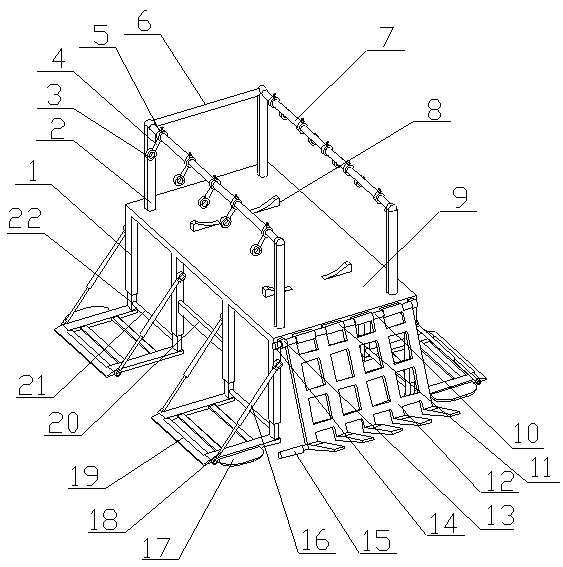

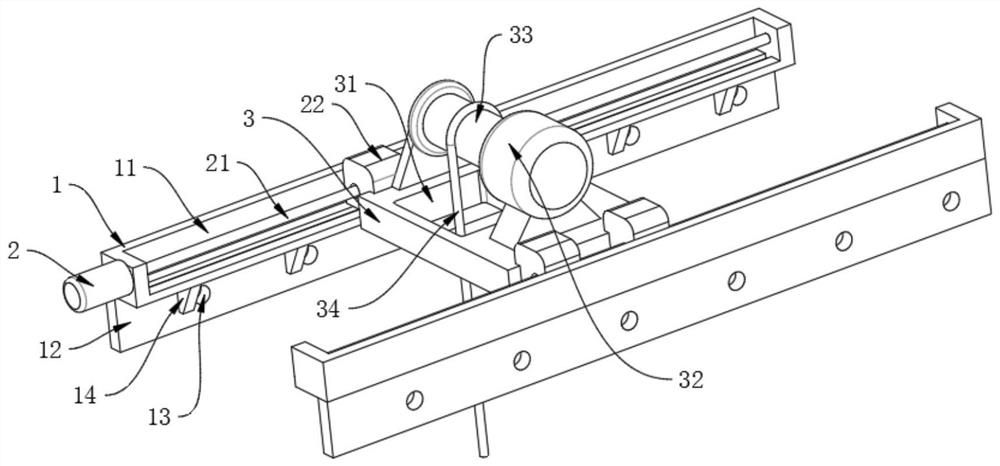

Automatic steel wire cutting, conveying and bending device

The invention discloses an automatic steel wire cutting, conveying and bending device and relates to the technical field of metal machining mechanical equipment. The device comprises a supporting bottom plate. The left side of the top of the supporting bottom plate is fixedly connected with first supporting rods which are symmetric. The tops of the two first supporting rods are fixedly connected with a first fixing outer frame and a second fixing outer frame correspondingly. The right side of the first fixing outer frame is fixedly connected with the left side of the second fixing outer frame,through holes are formed in the centers of the two ends of the first fixing outer frame and the second fixing outer frame correspondingly, the lower portion of the inner wall of the first fixing outer frame is rotationally connected with symmetric grooved pulleys, and the upper portion of the inner wall of the first fixing outer frame is rotationally connected with symmetric clamping rollers. According to the automatic steel wire cutting, conveying and bending device, the problems that existing steel wire straightening, cutting and bending need to be completed through manual operation, the efficiency is not high, and demands of modernized production are hard to meet are solved, and the purposes that operation is convenient, the workload of staff is lightened, and the automation degree isincreased are achieved.

Owner:浙江德耀金属制品有限公司

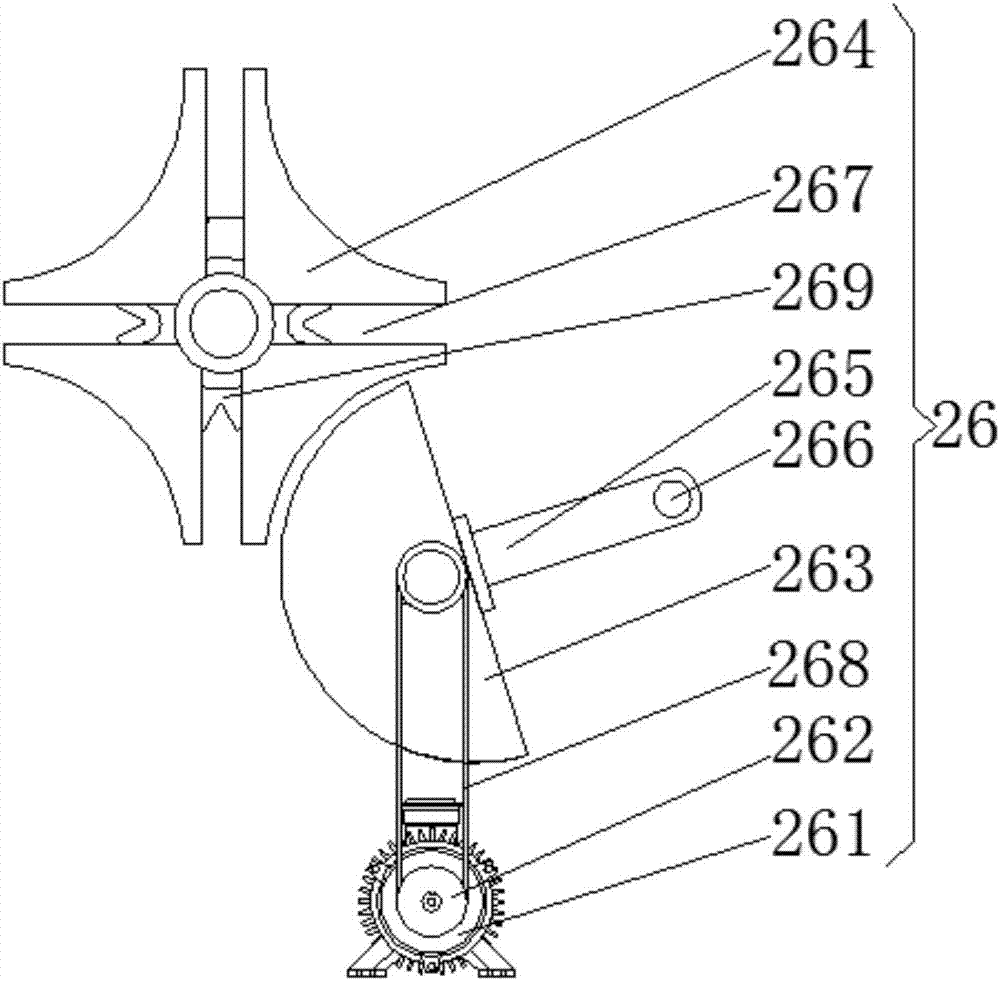

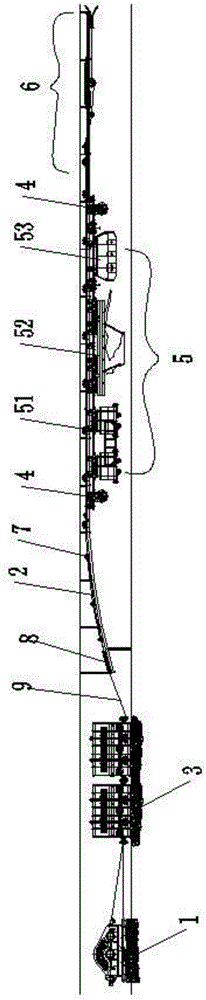

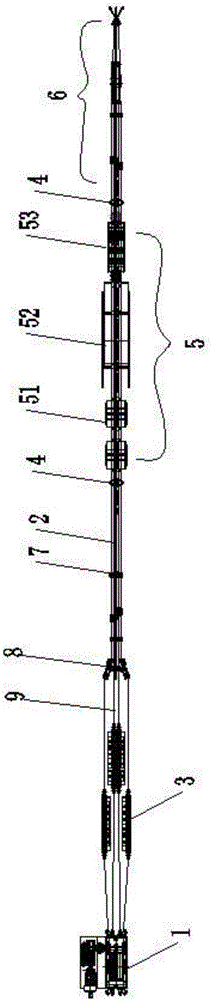

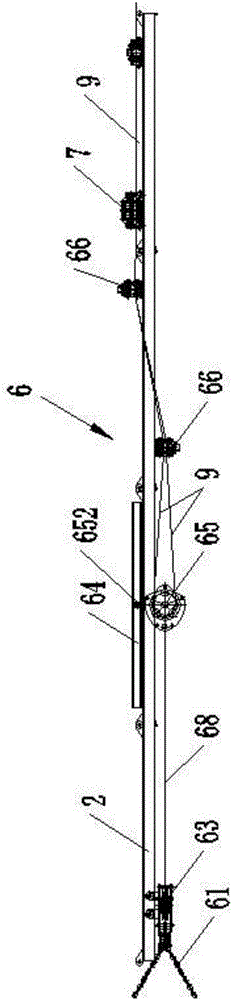

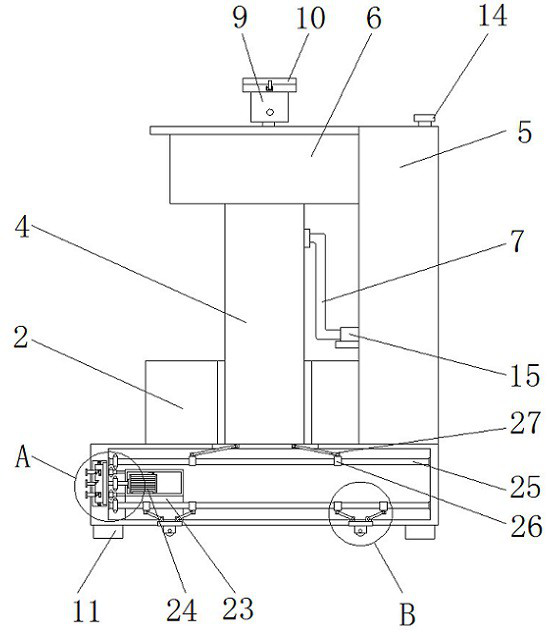

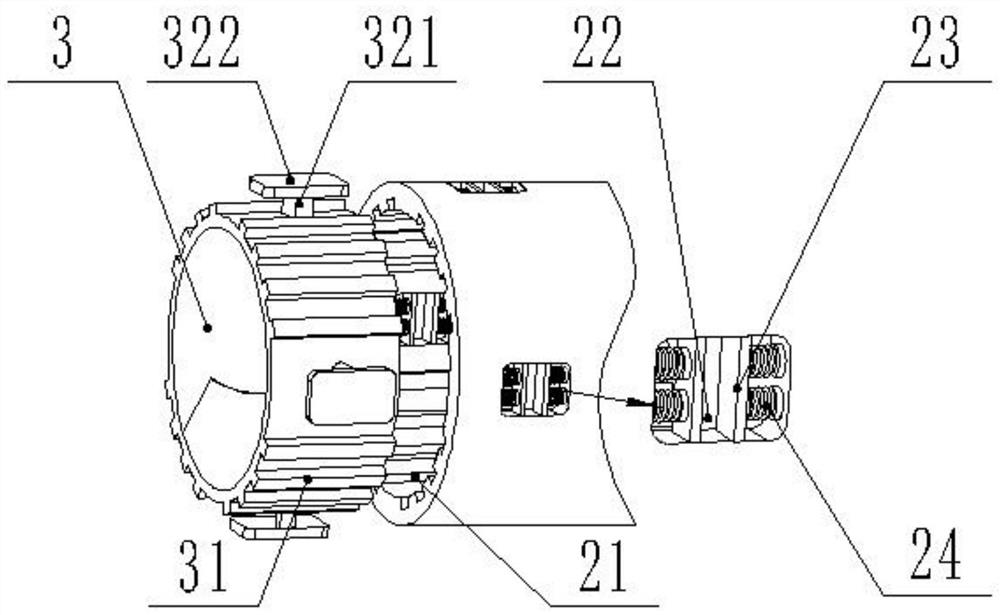

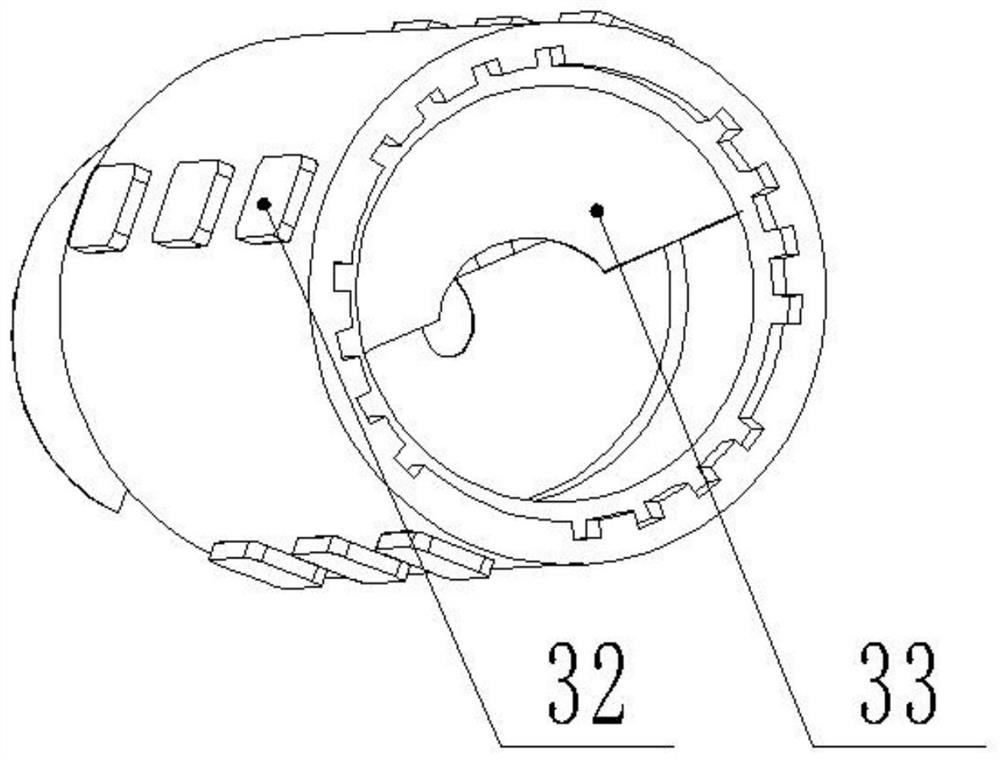

Double-rope traction monorail crane system

The invention relates to a double-rope traction monorail crane system. The double-rope traction monorail crane system comprises a power system, tensioning devices, a rail, a traction head system, a transporting system, a tail wheel system, double-rope pressing wheel sets, a rope winding and guiding wheel set and two traction steel wire ropes, wherein the rail is fixedly connected to the upper part of a mine cavity; the transporting system is movably connected with the rail; the traction head systems are arranged at the front part and the rear part of the transporting system and are also movably connected with the rail; a plurality of double-rope pressing wheel sets are fixedly connected with the rail; the rope winding and guiding wheel set is fixedly connected with the front end of the rail; the two traction steel wire ropes start from the power system, pass through the corresponding tensioning devices, then pass through the rope winding and guiding wheel set, return from the tail wheel system, and are fixed on the traction head system. Through the double-rope traction monorail crane system, the coal mine transportation requirements of large tonnage, long distance and high transportation quantity can be met; and the operation requirements of complex coal mine wells with large-inclination, variable-slope and multi-bending roadways can be met.

Owner:常州弘迪煤矿装备科技有限公司

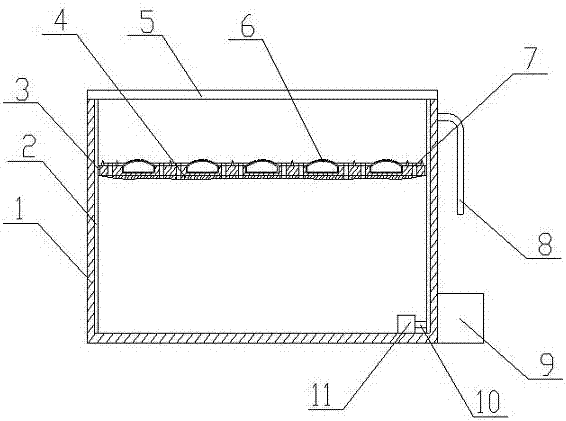

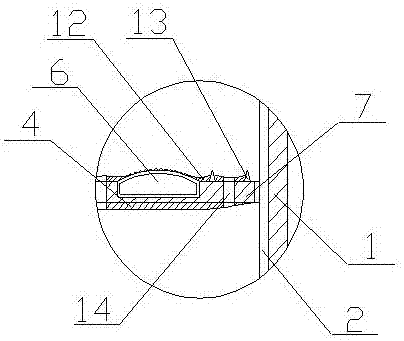

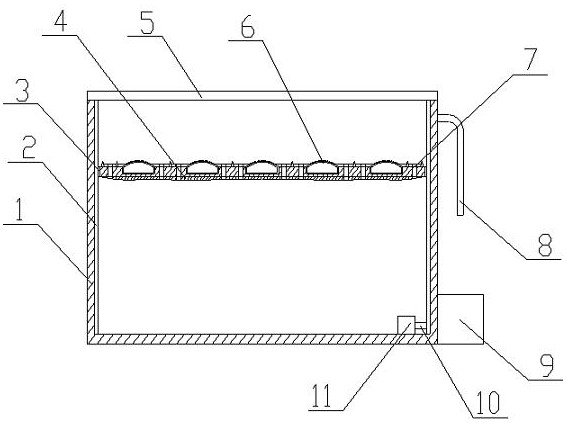

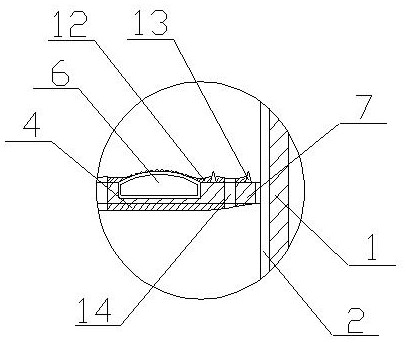

Logistic transportation aquatic product transportation box

ActiveCN107996489ASlow down the flowAvoid scaringPisciculture and aquariaRubber materialLogistics management

The invention discloses a logistic transportation aquatic product transportation box. By means of the logistic transportation aquatic product transportation box, water drops generated by water body vibration in the transportation box are scattered through scattering protrusions, so that striking sound generated when the water drops fall back to the water surface is lowered. The logistic transportation aquatic product transportation box is characterized in that a box lid is arranged at the top of a main body box, a foam pad is arranged on the box lid, a through hole is formed in one side of themain body box, one end of a connecting pipe is arranged at one side of the main body box and corresponds to the through hole in one side of the main body box, two guiding rods are arranged on the inner walls of the two sides of the main body box respectively, a floating plate is arranged in the main body box, clamping grooves are formed in the two ends of the floating plate respectively and are clamped on the two guiding rods respectively, multiple gasbags are arranged on the floating plate separately, arcs are arranged on the outer side faces of the gasbags, multiple semispherical protrusions are arranged on the outer side faces of the gasbags and are made from rubber materials, an elastic pad is arranged at the side, close to the box lid, of the floating plate, multiple springs are arranged in the elastic pad, and the multiple scattering protrusions are arranged on the elastic pad separately.

Owner:徐州新南湖科技有限公司

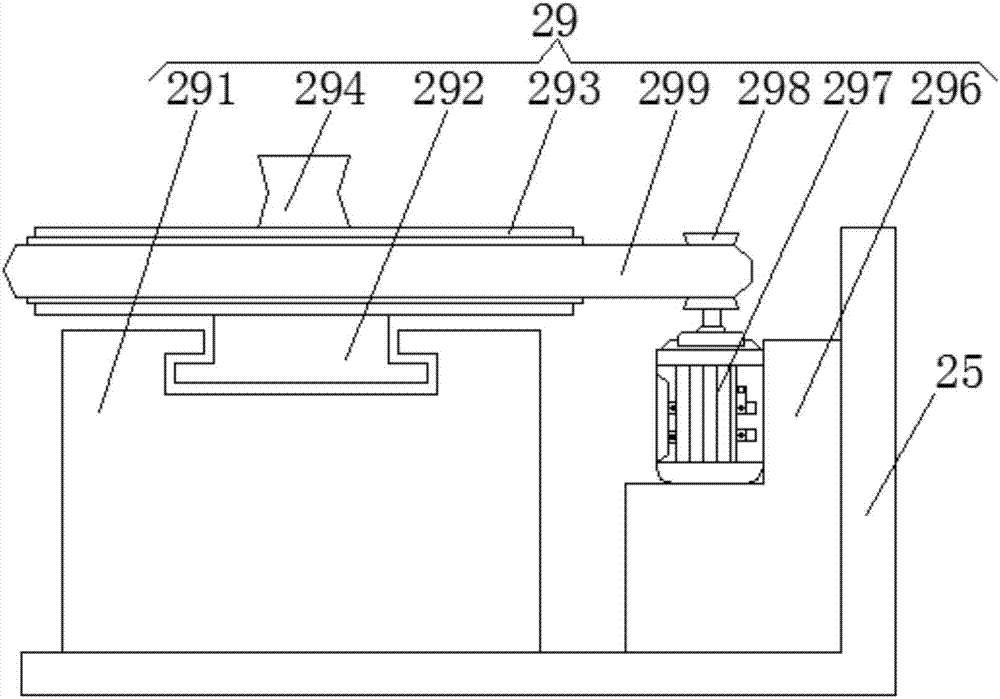

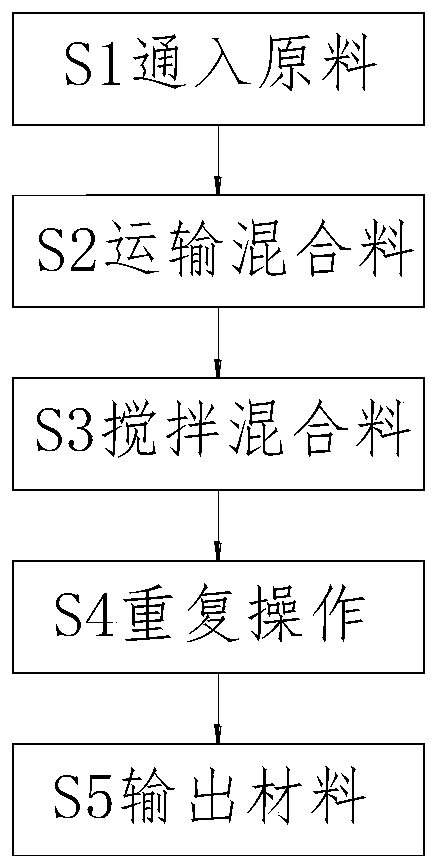

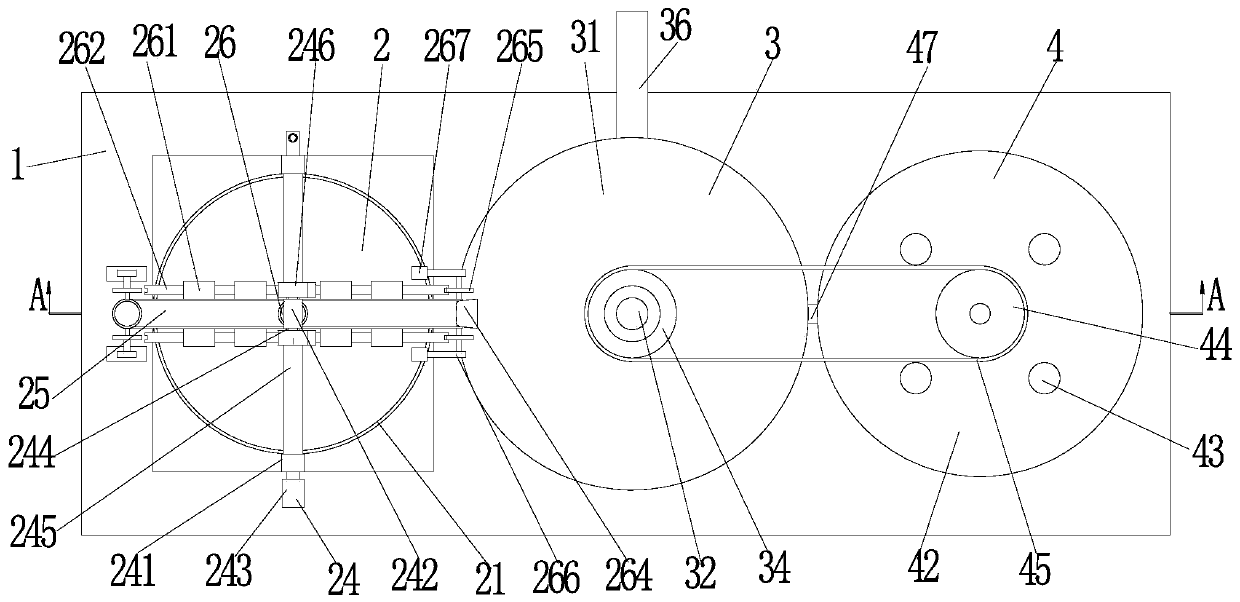

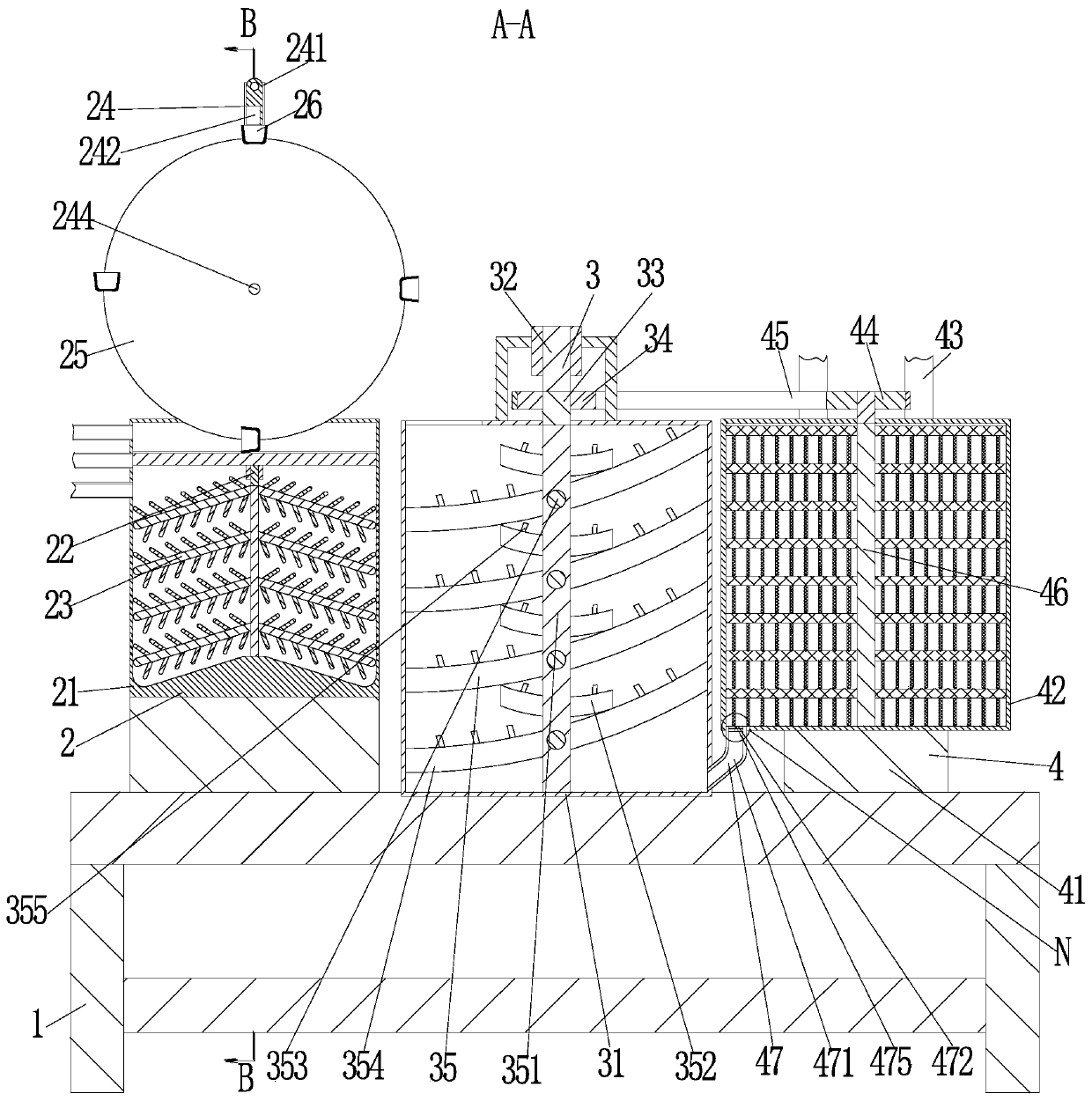

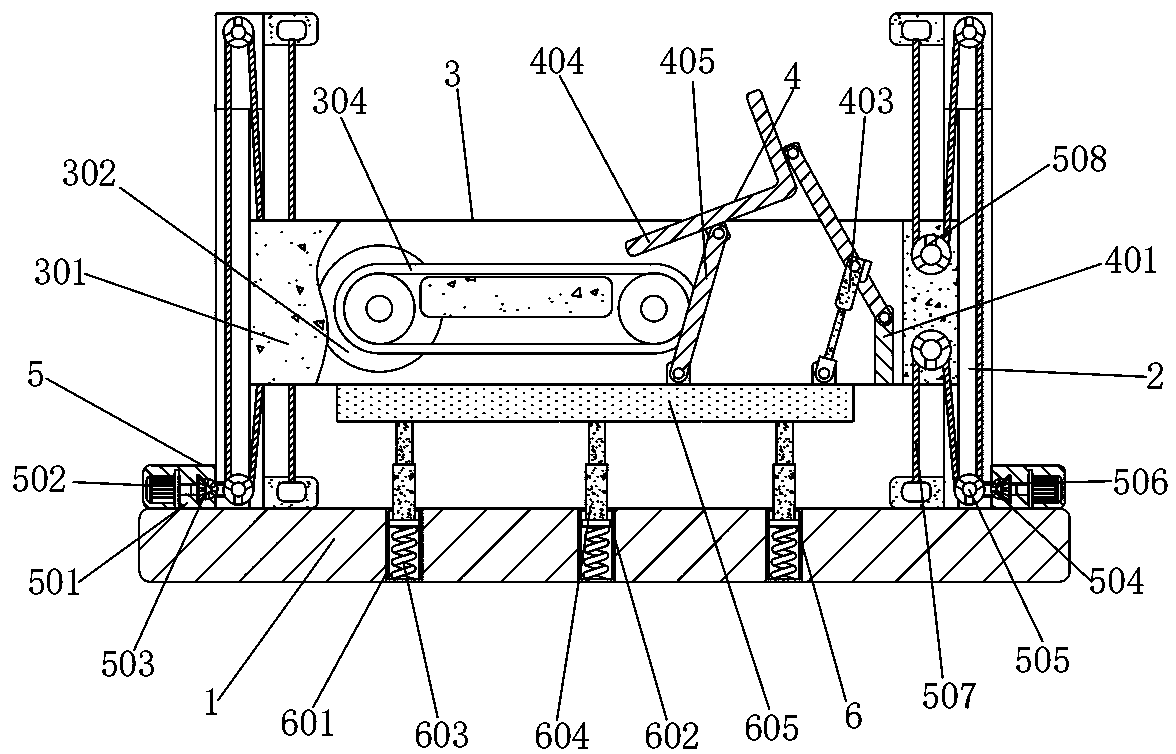

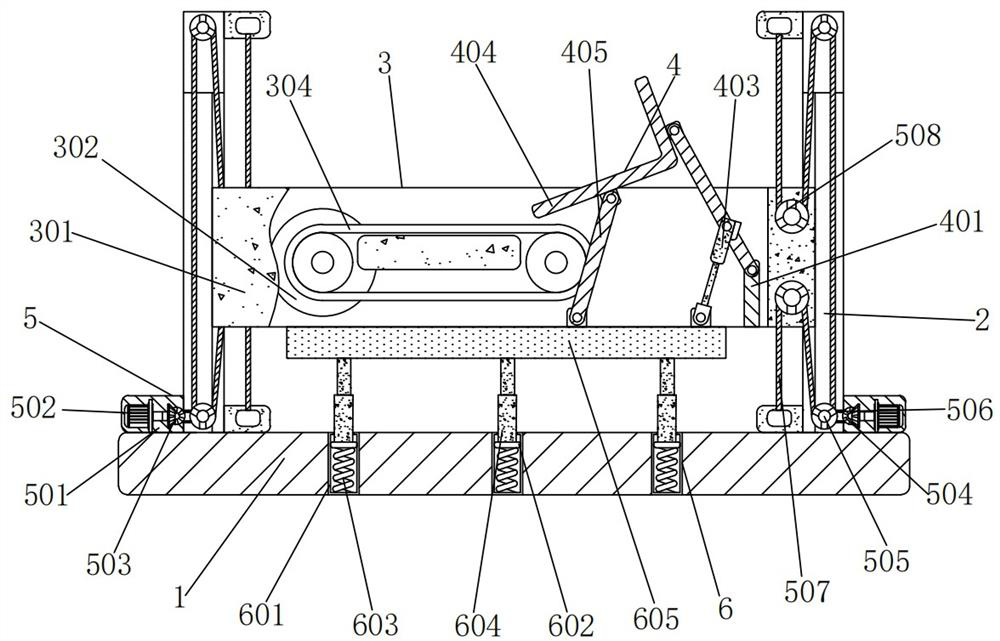

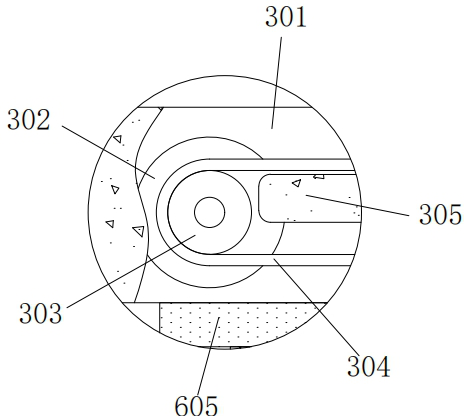

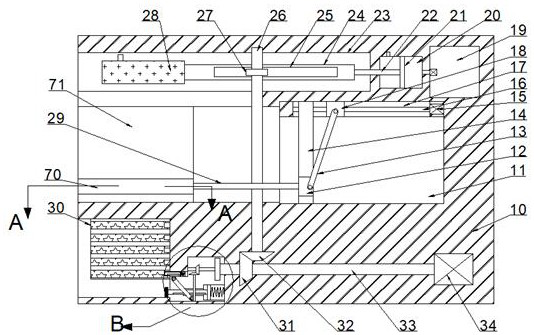

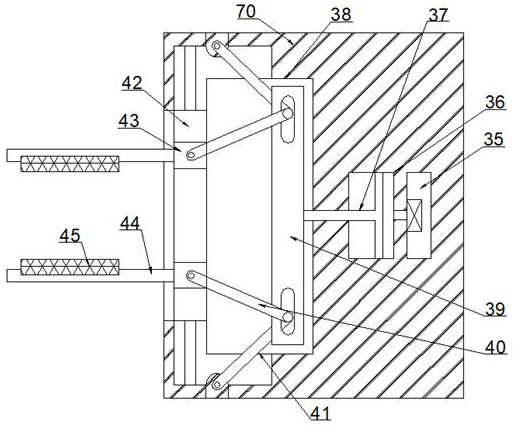

Cement concrete preparation system and preparation method thereof

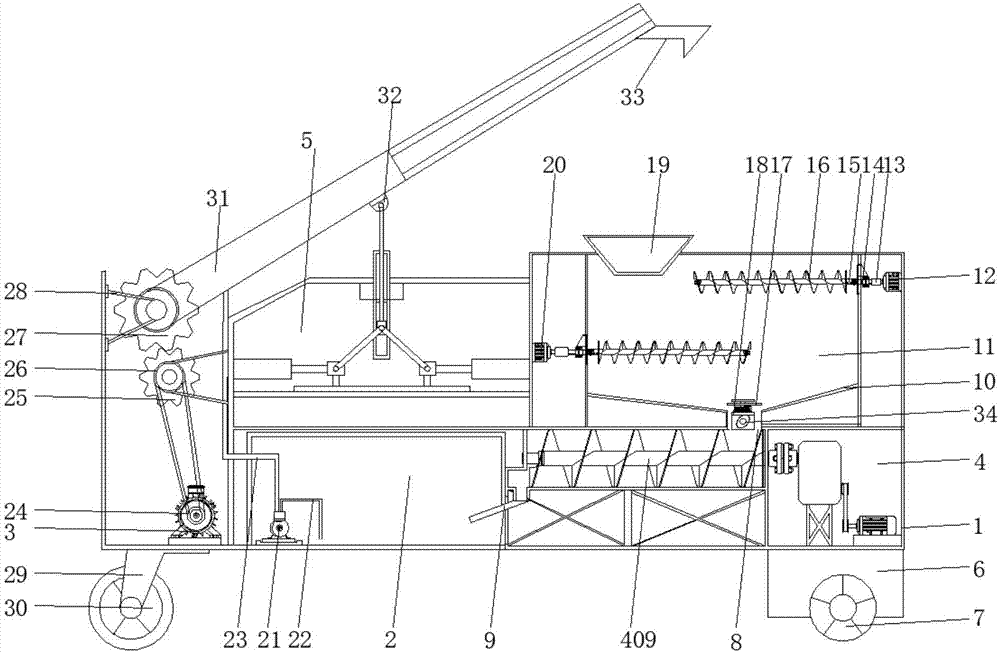

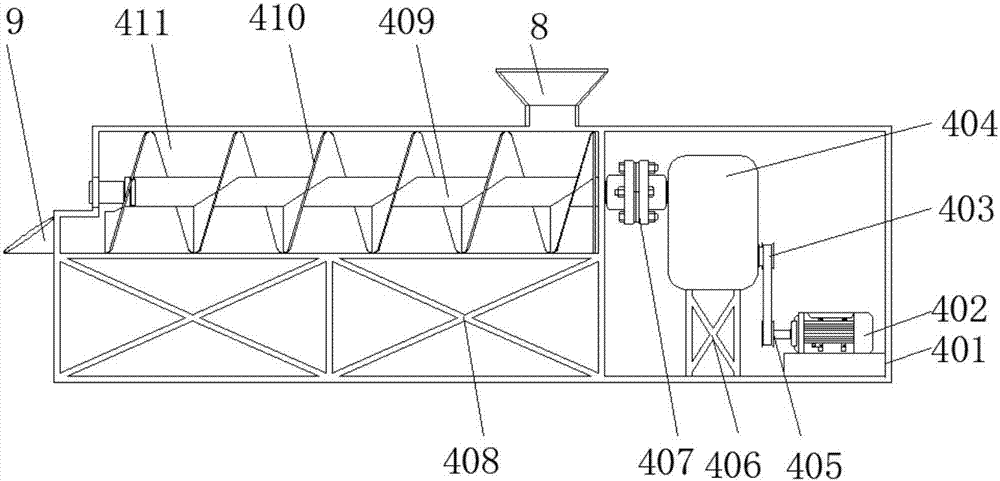

ActiveCN111531717AStir wellFully transportedDischarging apparatusTransportation and packagingWorkbenchCement Material

The invention relates to a cement concrete preparation system and a preparation method thereof. The cement concrete preparation system comprises a workbench, a first mixing device, a stirring device and a second mixing device; the upper end of the left side of the workbench is provided with the first mixing device, the right end of the first mixing device is provided with the stirring device, andthe right end of the stirring device is provided with the second mixing device; and the first mixing device comprises a first stirring tank, a first motor, a first stirring frame, a supporting frame,a disc plate and a conveying frame. According to the cement concrete preparation system and the preparation method thereof, a solid raw material and a liquid raw material are uniformly stirred throughthe first mixing device and the second mixing device, meanwhile, the uniformly-stirred solid mixture and liquid mixture are subjected to quantitative conveying, accordingly, the stirring amount of the stirring device is controlled so that the purpose of sufficiently stirring the mixtures quantitatively can be achieved, and the mixtures are sufficiently stirred and conveyed through the stirring device.

Owner:临海市强广建材股份有限公司

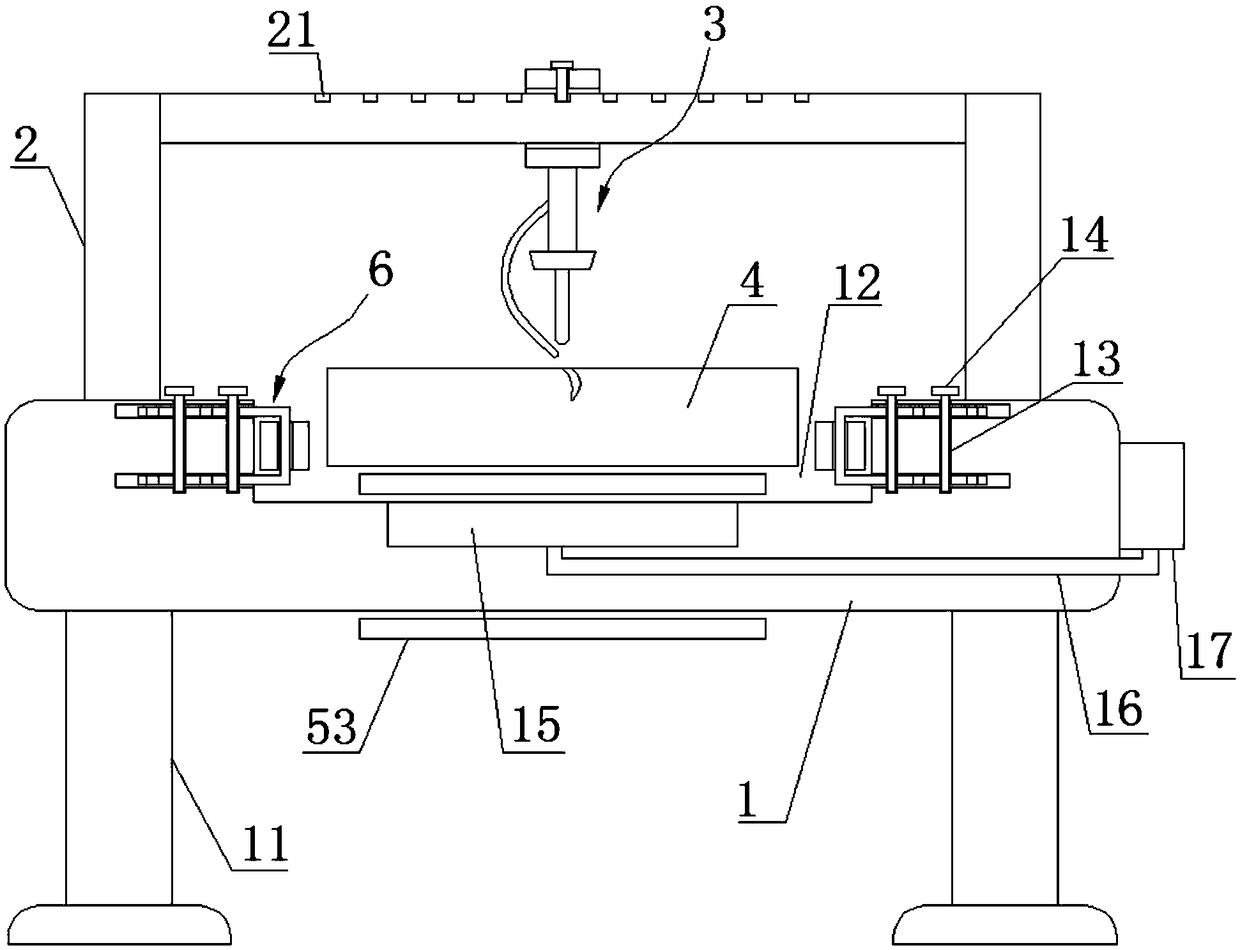

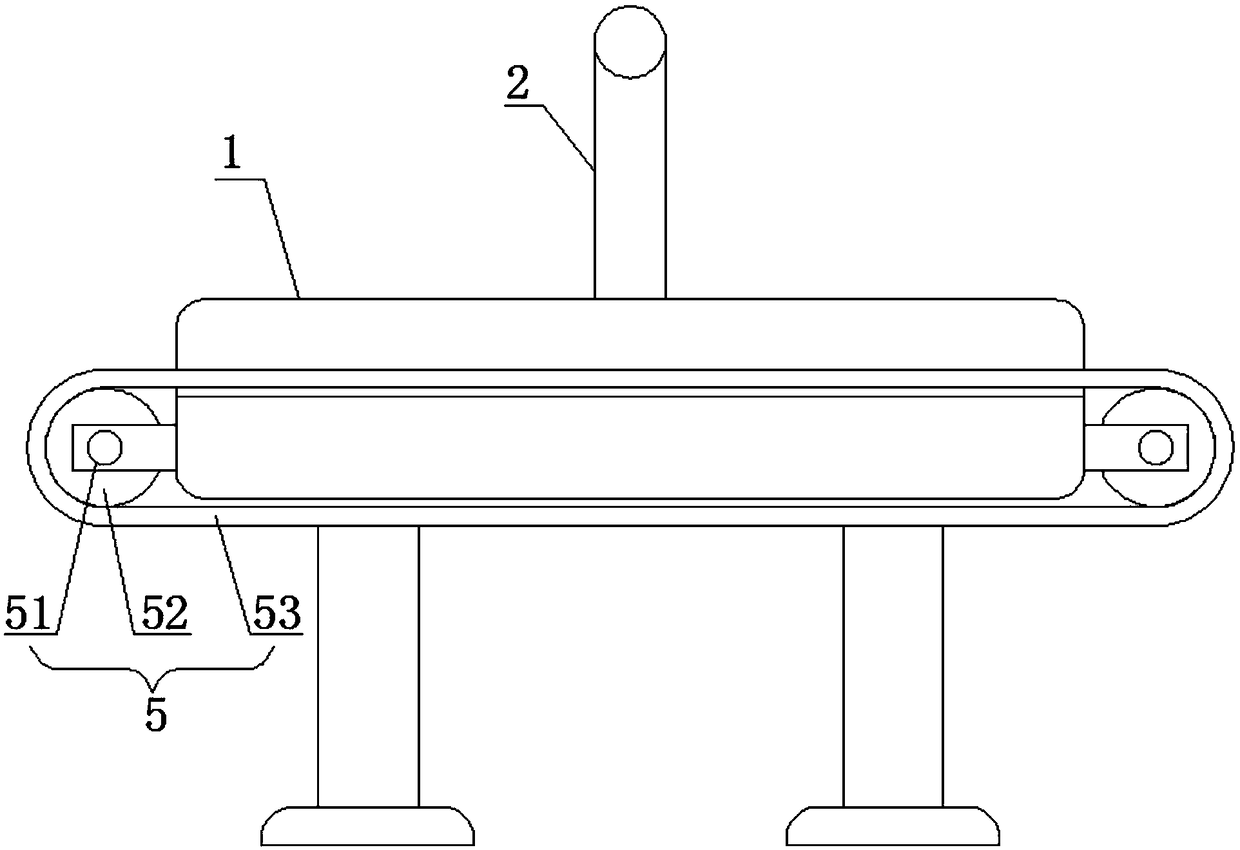

Adjustable automatic welding device for machining

InactiveCN109175800ATo achieve a firm effectAvoid offsetWelding/cutting auxillary devicesAuxillary welding devicesMachiningMulti directional

The invention relates to the technical field of machining, in particular to an adjustable automatic welding device for machining. The upper end of a workbench is provided with a U-shaped groove, wherein the U-shaped groove is formed between two stand columns of a U-shaped bracket. The workbench is further provided with a conveying device. The conveying device is composed of rotating shafts, rollerwheels, a conveying belt and a motor, wherein the rotating shafts are connected to the front end face and the rear end face of the workbench in a rotary manner; each roller wheel is fixedly connectedto the corresponding rotating shaft in a sleeving manner; the conveying belt is used for connecting the two roller wheels; and the motor is connected with one end of one of the rotating shafts. The motor is mounted on the side end face of the workbench. The upper end of the conveying belt is connected with a welded workpiece, wherein the welded workpiece is located in the U-shaped groove. A transverse section of the U-shaped bracket is connected with a movable welding device. Two limiting and guiding devices are symmetrically connected to the side walls of the two ends of the U-shaped groovein an inserted manner. According to the adjustable automatic welding device for machining, the purpose of welding the different welded workpieces is achieved through multi-directional adjustment, andthe quite high practicability is achieved.

Owner:新昌县利安轴承有限公司

Closed-type hydrodynamic transport pipeline

InactiveCN102887365AHigh speedAchieve the purpose of transportationConveyorsProcess engineeringEnergy consumption

The invention aims at providing a closed-type hydrodynamic transport pipeline which mainly comprises a high-strength closed pipeline, a delivery station built at an inlet of the pipeline, and a receiving station built at an outlet of the pipeline. After the aim of the pipeline is realized, people can deliver articles needing to be transported to a downstream city into the pipeline via a transport belt, and the articles are rapidly transported into the receiving station at the downstream outlet via strong hydrodynamic force in the pipeline. Therefore, the aim of helping the people to transport the articles without any fuel energy consumption can be achieved; and the beneficial effects and the functions of the pipeline are very obvious.

Owner:王先全

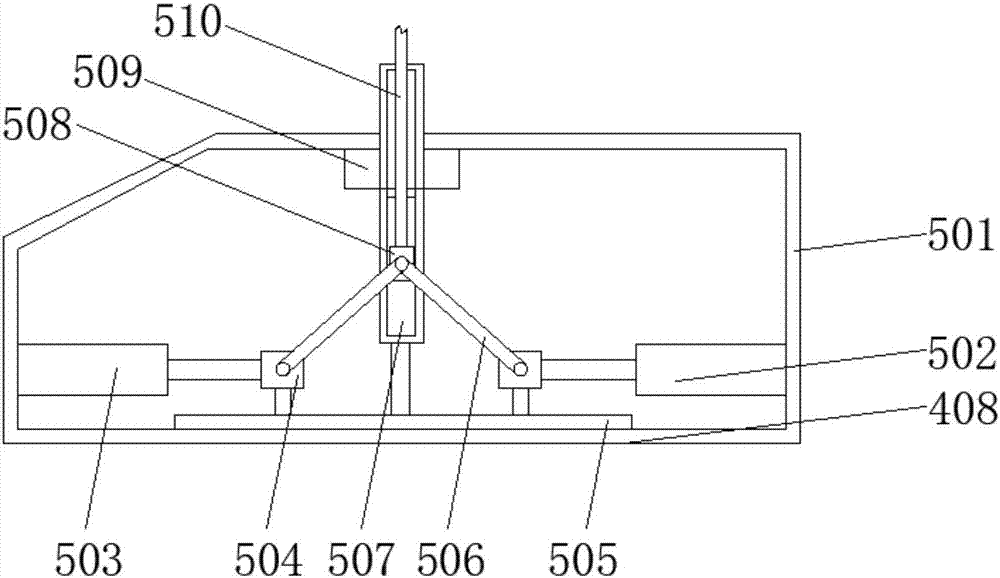

Intelligent port loading, unloading and conveying equipment

ActiveCN111071704AIncrease workforceSolve the problem of inconvenient transportationConveyorsConveyor partsElectric machineryStructural engineering

Owner:NANJING PORT LONGTAN CONTAINER CO LTD

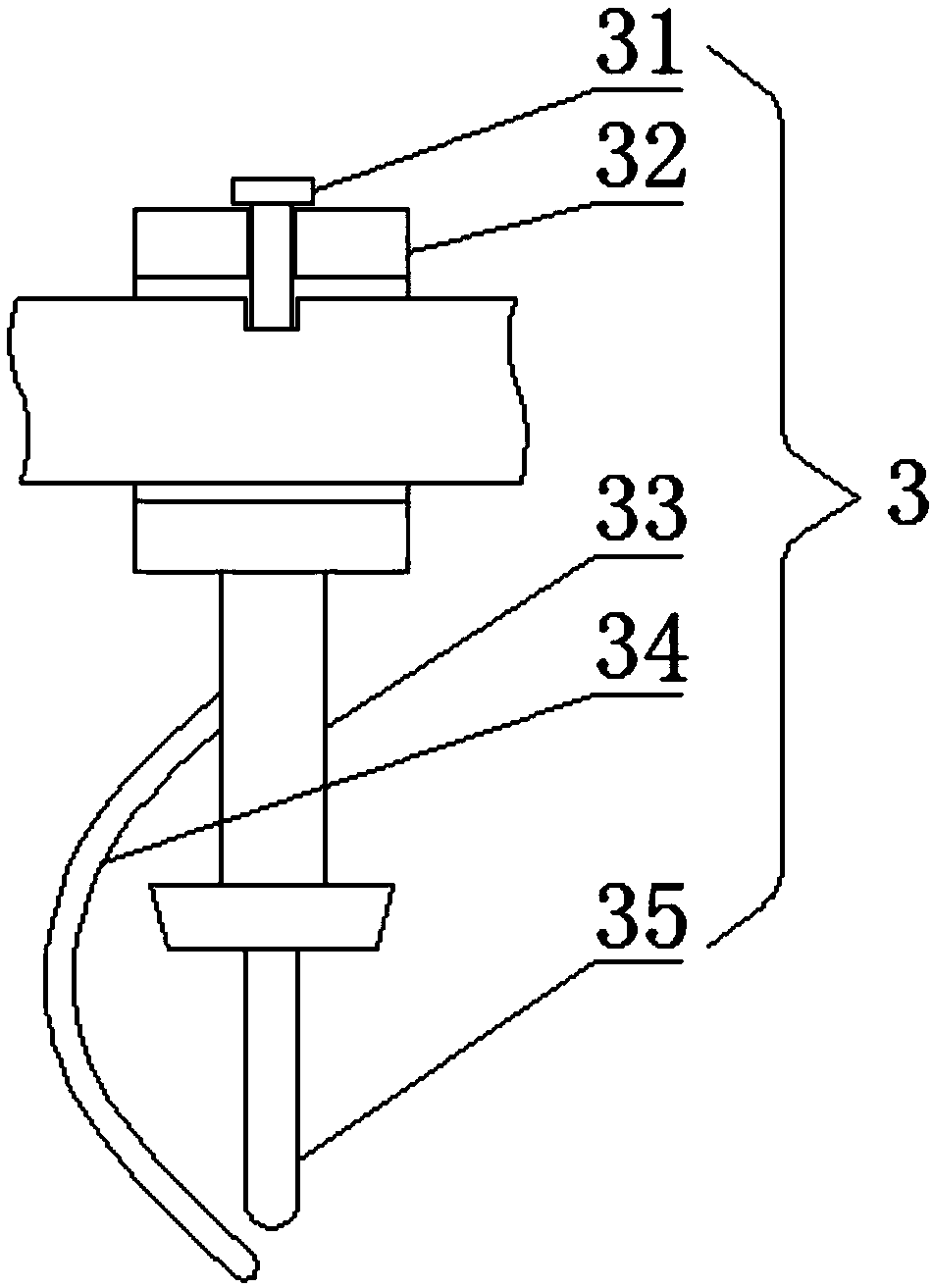

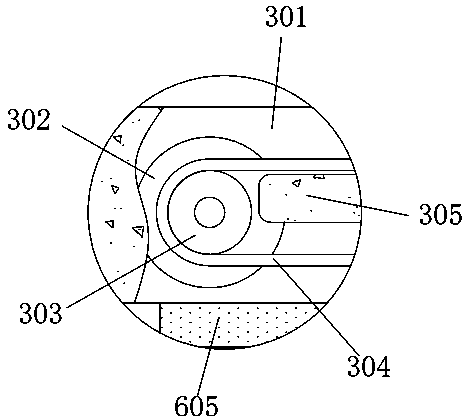

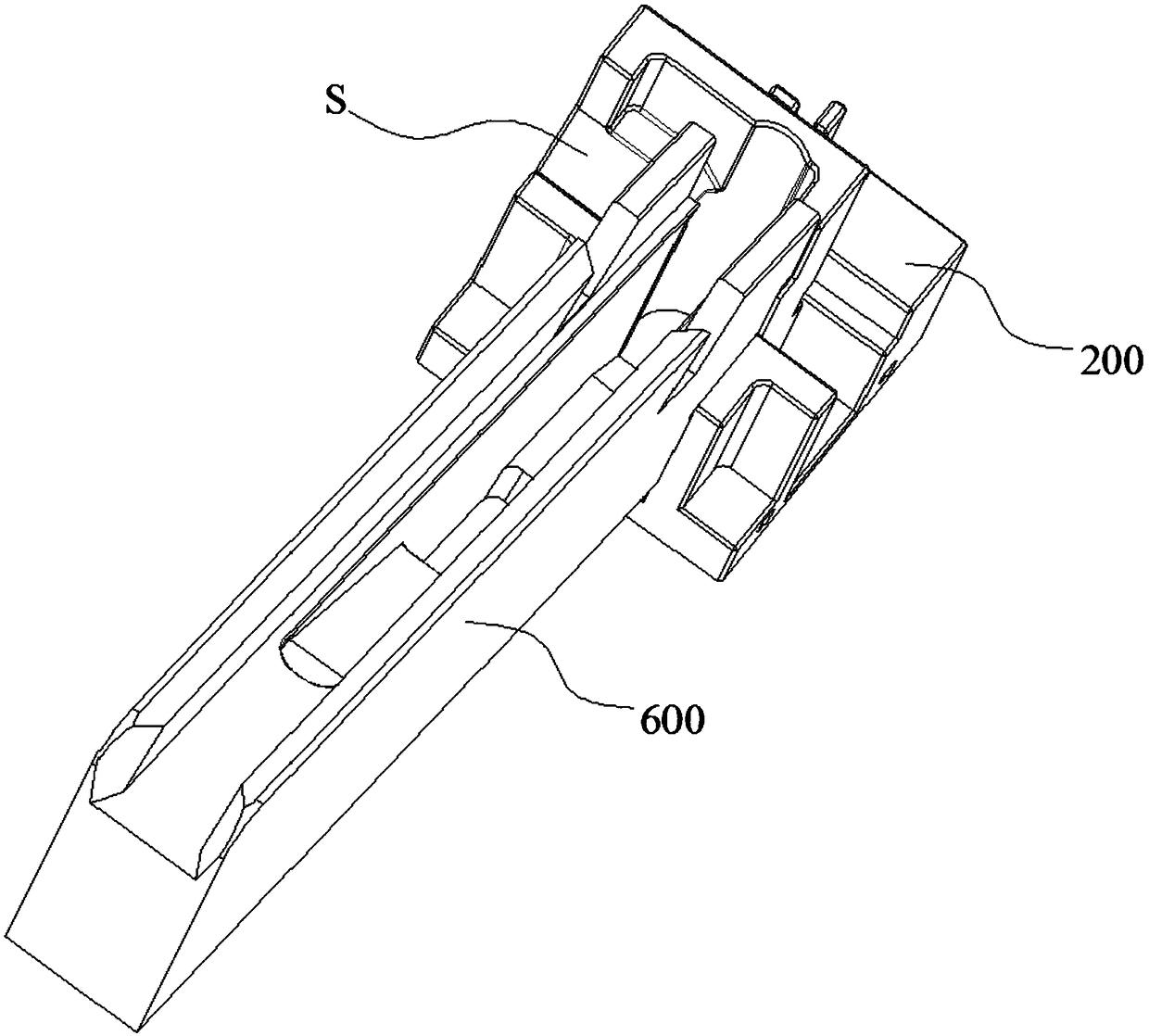

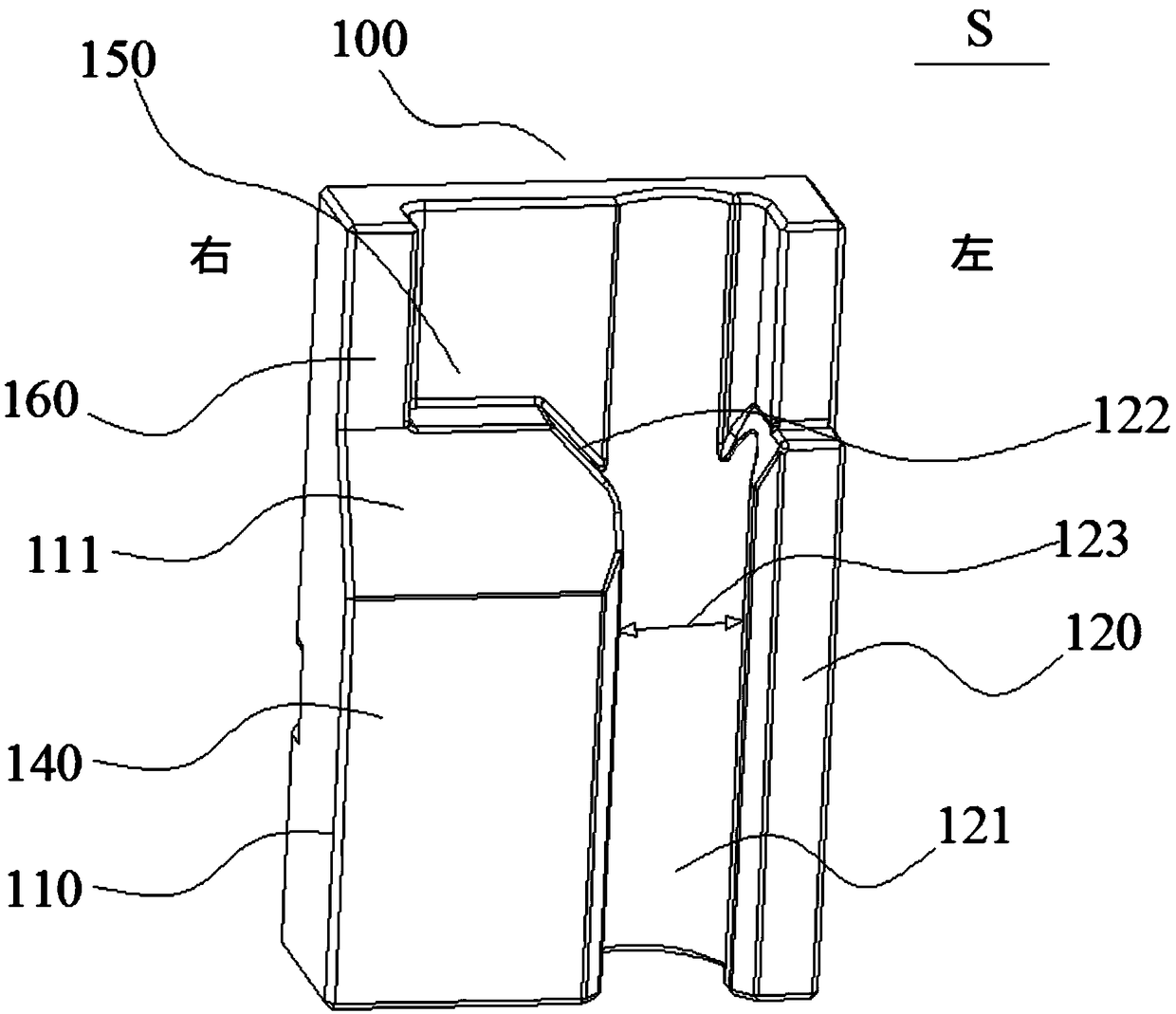

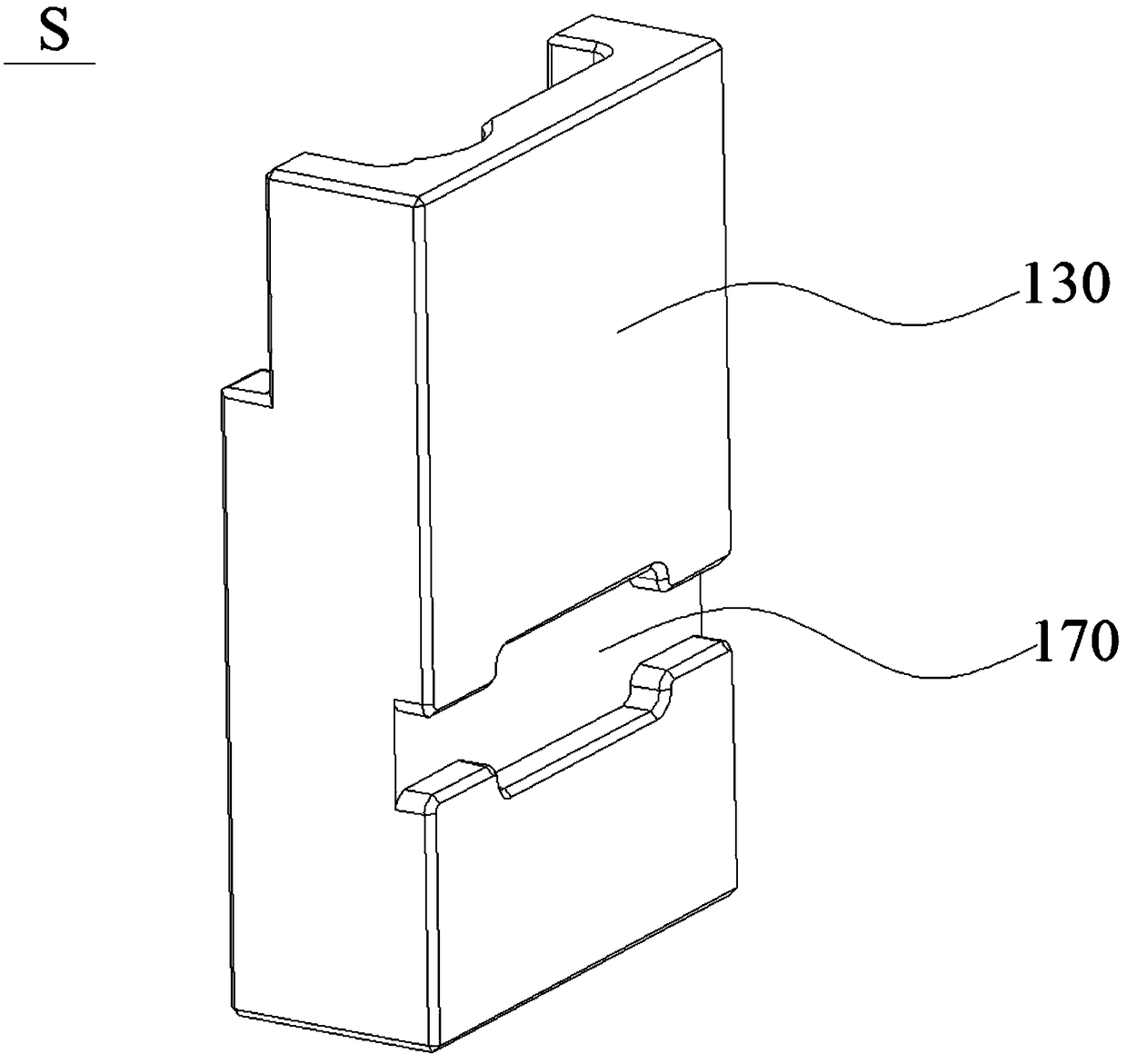

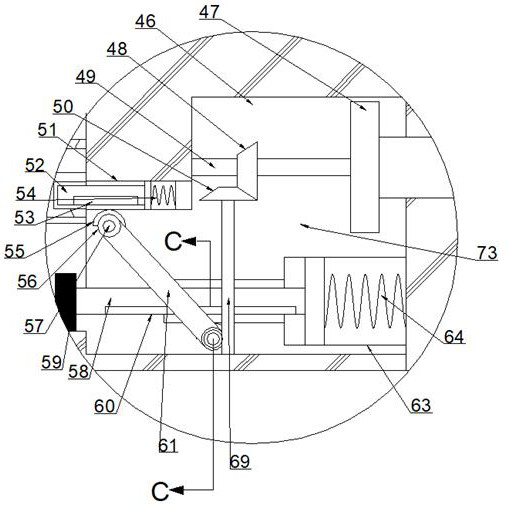

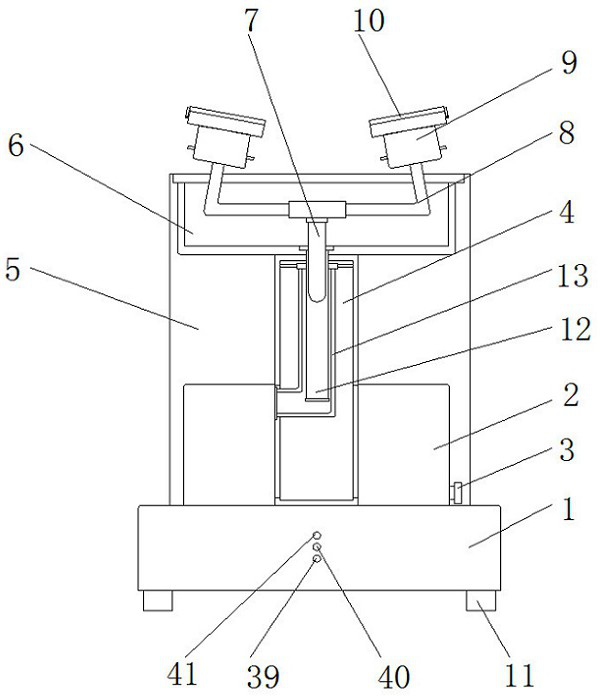

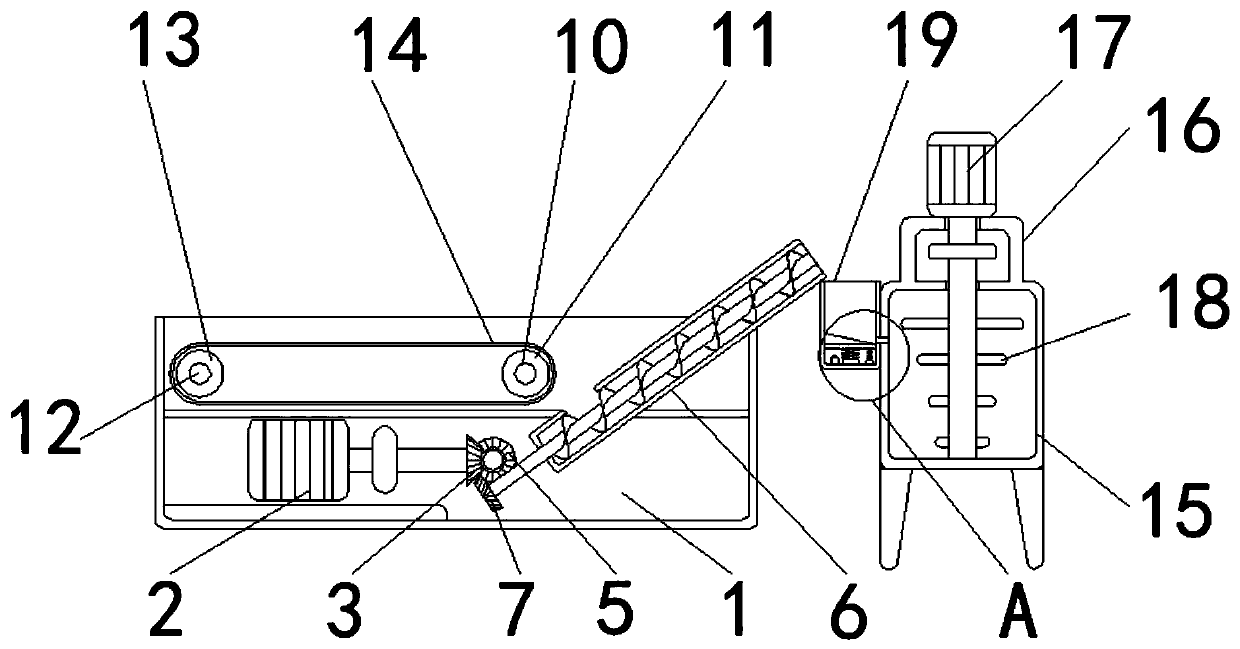

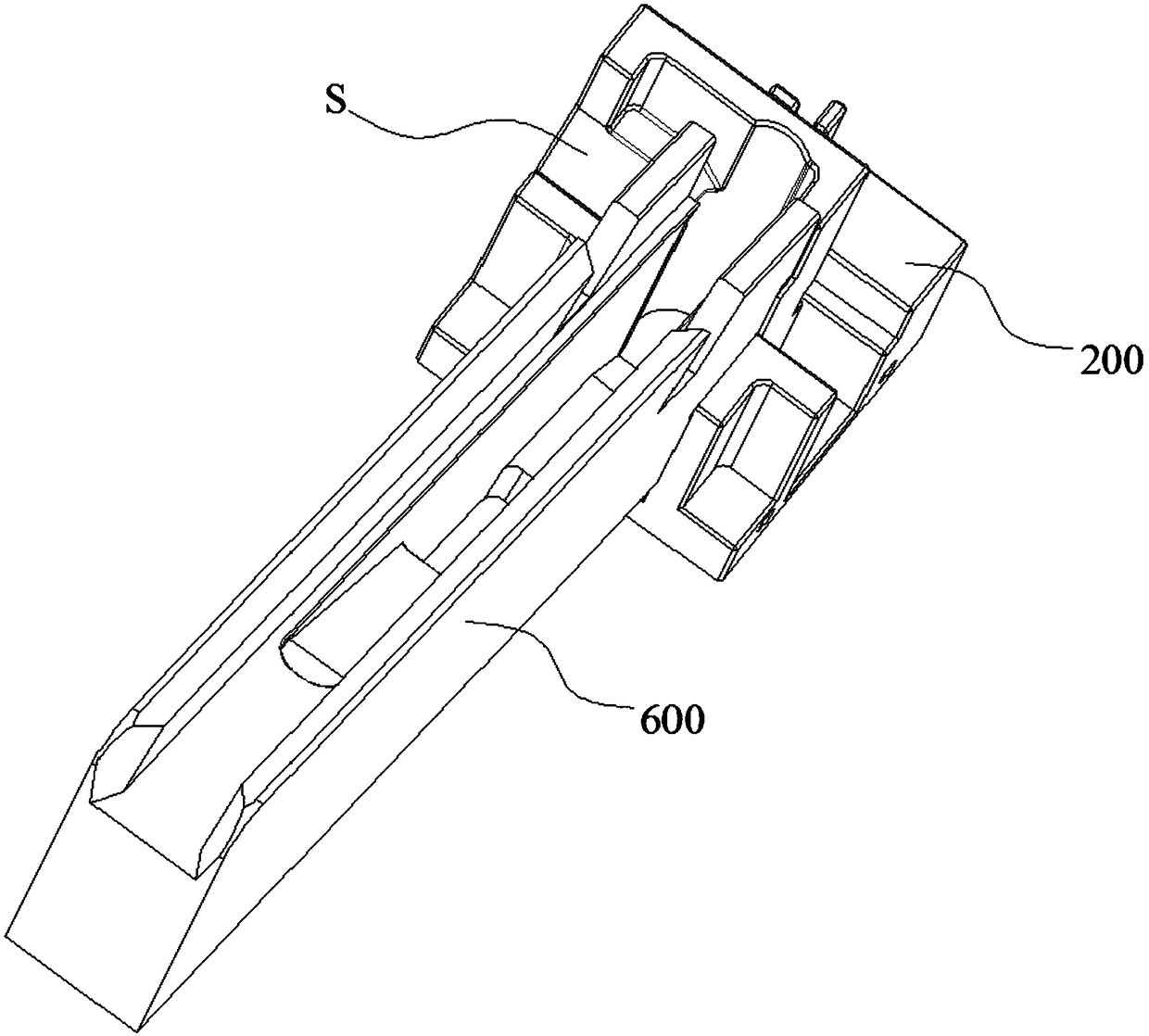

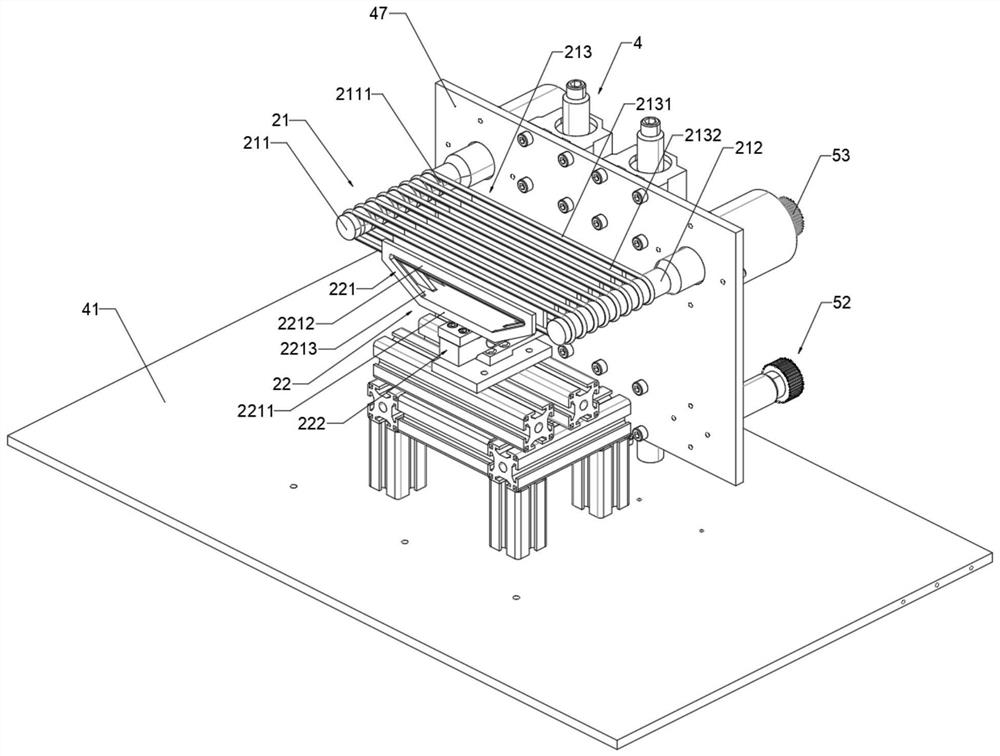

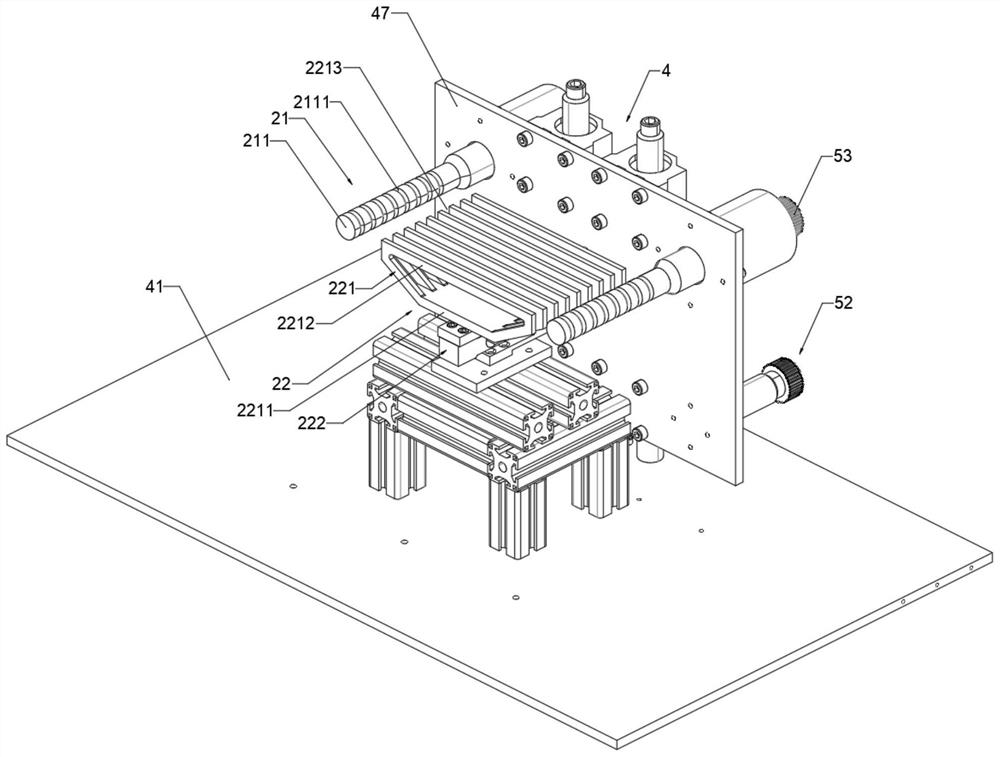

Reaction cup pusher and reaction cup loading device

ActiveCN109142771AAchieve the purpose of transportationAvoid accumulationMaterial analysisBiochemical engineering

The invention provides a reaction cup pusher and a reaction cup loading device, and the reaction cup pusher comprises a cup body blocking part for blocking a reaction cup located at a waiting station,and a cup body guiding part for guiding a single reaction cup located at the waiting station to the next station, the cup blocking part and the cup guiding part can be respectively butted with the waiting station through the movement of the pushing block body. Because the cup body guiding part capable of accommodating a single reaction cup and the cup body blocking part capable of blocking the reaction cup are arranged, the cup body guiding part or the cup body blocking part is butted with the waiting position by moving the reaction cup pusher, so that the purpose of the reaction cup transporting is realized, in the process of guiding the reaction cup to the next station, the reaction cup passes through a certain conveying path, so that the final outlet of the reaction cup is staggered from the reaction cup inlet at the waiting station, and the control flow can be simplified.

Owner:MACCURA MEDICAL INSTR CO LTD

Municipal engineering environmental sanitation garbage can carrying frame

ActiveCN108033093ACause damageReduce physical exertionRigid containersInternal fittingsArchitectural engineeringMagnet

The invention provides a municipal engineering environmental sanitation garbage can carrying frame. The frame is used in cooperation with an electric tricycle. Five garbage cans are carried at the same time, and the carrying frame can be used for carrying and unloading on the garbage cans. The five garbage cans are carried at the same time, the carrying efficiency of the garbage cans is greatly improved, the garbage can is convenient and fast to assemble and disassemble, and the physical consumption of the sanitation workers is reduced. The carrying frame is characterized in that one ends of the four vertical rods are vertically arranged on a fixed plate, and are positioned at four corners of the fixed plate; the fixed plate is in a cuboid shape, a magnet is arranged at the bottom of the fixing plate, and two of the four vertical rods are in a group; the other ends of the two vertical rods in the same group are connected through sliding rods, and the two sliding rods are parallel to each other; and a plurality of clamping rings are arranged on the sliding rods in a sleeved mode and are fixed through bolts, one ends of the connecting rods are connected with the clamping rings, fixing rings are arranged at the other ends of the connecting rods, and the other ends of the two vertical rods on the front side are connected through a limiting rod.

Owner:XUZHOU CHUANGZHISHE GENERAL TECH IND RES INST CO LTD

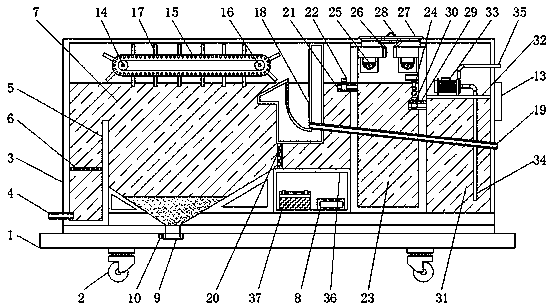

Layered sewage treatment transportation device

InactiveCN110498545AEasy to handleControl flow rateWater treatment parameter controlWater/sewage treatment by irradiationSludgeSewage treatment

The invention discloses a layered sewage treatment transportation device which comprises a bottom plate, a tank body, a vertical plate, a precipitation cabin, a sterilization cabin and a clean water cabin, wherein universal wheels are mounted at four surface corners of the bottom of the bottom plate; the tank body is mounted at the top of the bottom plate; a water inlet tube is mounted on one sideof the tank body; a control button is mounted on the other side of the tank body; the precipitation cabin is arranged on one side of the bottom inside the tank body; and a motor case is mounted at the top end inside the tank body above the precipitation cabin. Due to adoption of the precipitation cabin, sludge can be precipitated, heavy impurities such as sludge sand precipitated down can be discharged through a sludge discharge tube, the problem of sludge can be rapidly, conveniently and thoroughly solved, the device can be prevented from damage, floating impurities can be treated by using flutter boards, a dreg collection cabin and a floating dreg discharge tube, the floating impurities can be rapidly discharged, a filtering net can be prevented from being damaged, and the service lifeof the filtering net can be prolonged.

Owner:宁夏丝路征信有限公司

Conveying method for arranging transmission and power systems on roads

InactiveCN106740892AAchieve the purpose of transportationRailway componentsRailway system combinationsAutomotive engineeringTransmission system

A conveying method for arranging transmission and power systems on roads is characterized by comprising the following steps: paving devices with a mechanical power driving function, including a power system and a transmission system, on various tracked or trackless roads to form various power roads with a power driving function; and driving vehicles to run on the various power roads by using motors or hydraulic power systems fixed on the roads as power, so that the purpose of road conveying is achieved.

Owner:徐林波

Excavator auxiliary walking device

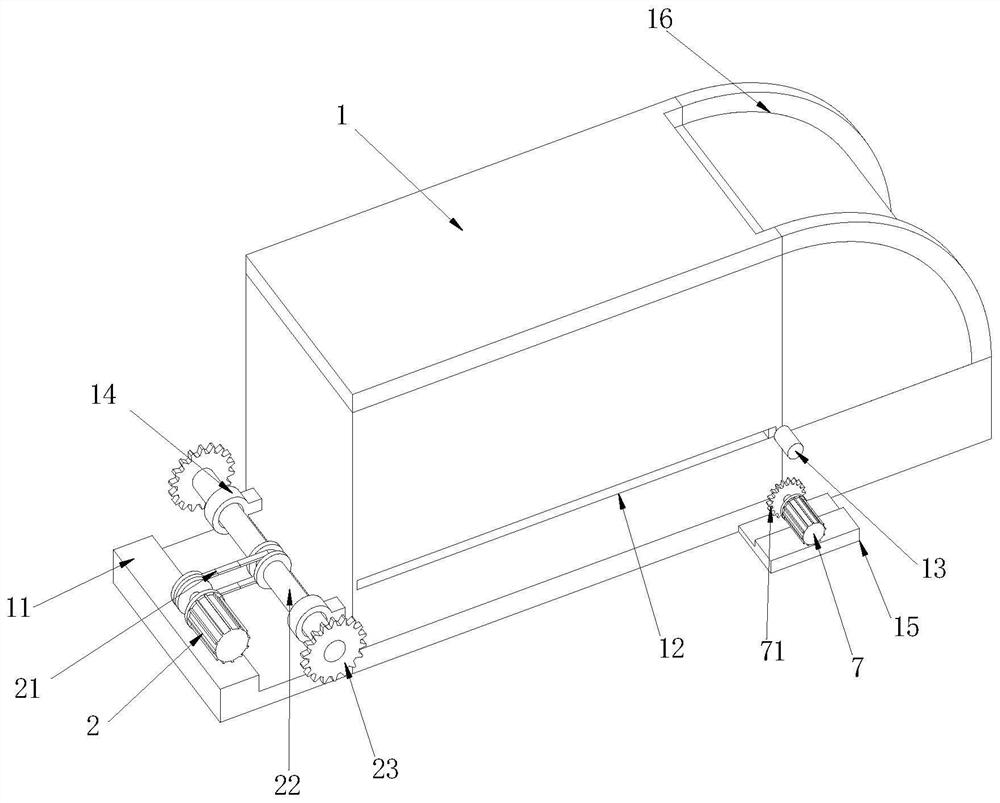

PendingCN109941179AAchieve the purpose of transportationEasy to transportVehicle carriersGear wheelExcavator

The embodiment of the invention discloses an excavator auxiliary walking device which comprises a vehicle body, a rotating belt, walking wheels and a turning plate. One end of the turning plate is hinged to the vehicle body. A fixing piece is arranged at the hinged position of the vehicle body and the turning plate. A placement cavity is formed in the top end of the vehicle body. A gear accelerator is fixedly connected into the placement cavity. A connecting shaft is slidingly connected with the vehicle body. A slide groove is formed in the vehicle body. An input gear is fixedly connected withthe connecting shaft. A transmission gear is fixedly connected with an input shaft of the gear accelerator. After the connecting shaft slides, the input gear and the transmission gear are separated,and a limiting piece for fixing the connecting shaft is arranged on the vehicle body. When an excavator is carried through the device, the cost for using a vehicle trailer can be saved, the time for waiting for the vehicle trailer can be shortened, the maneuverability of the excavator is increased, and therefore the excavator can be conveniently carried at any time.

Owner:姜冬志

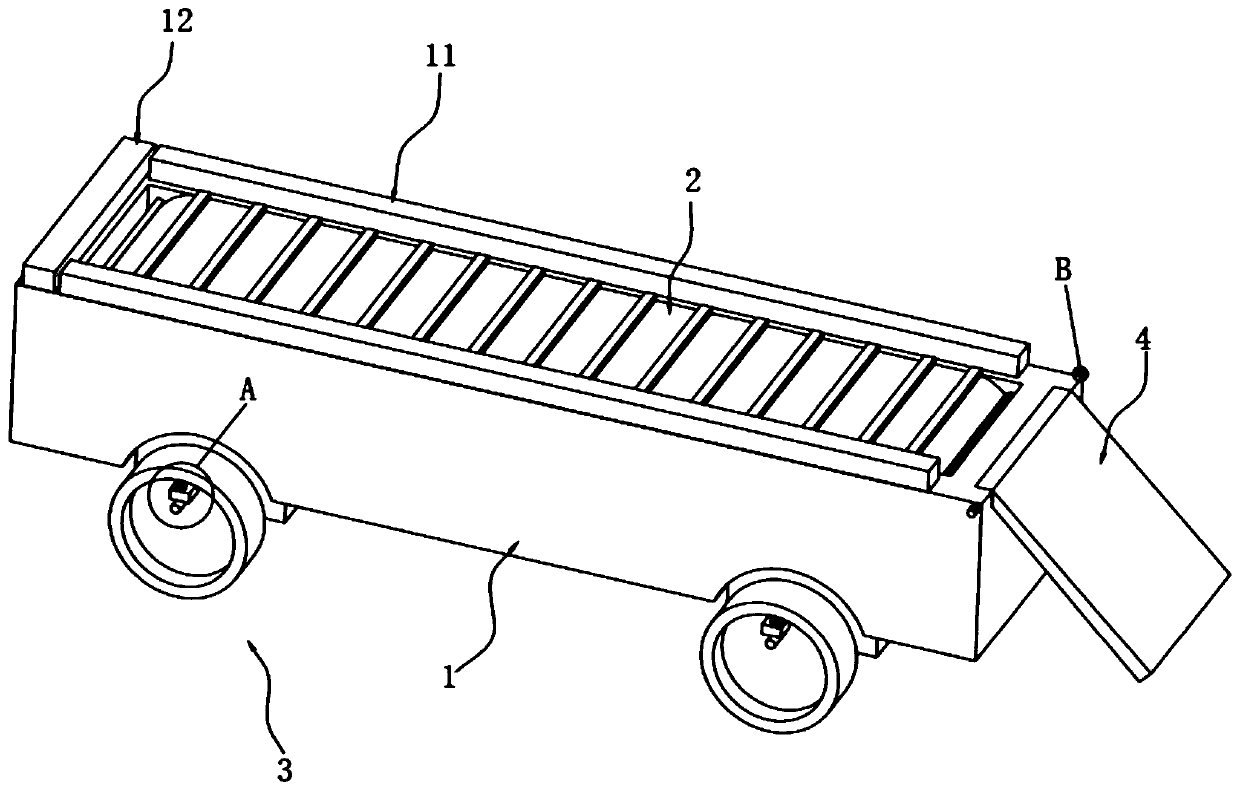

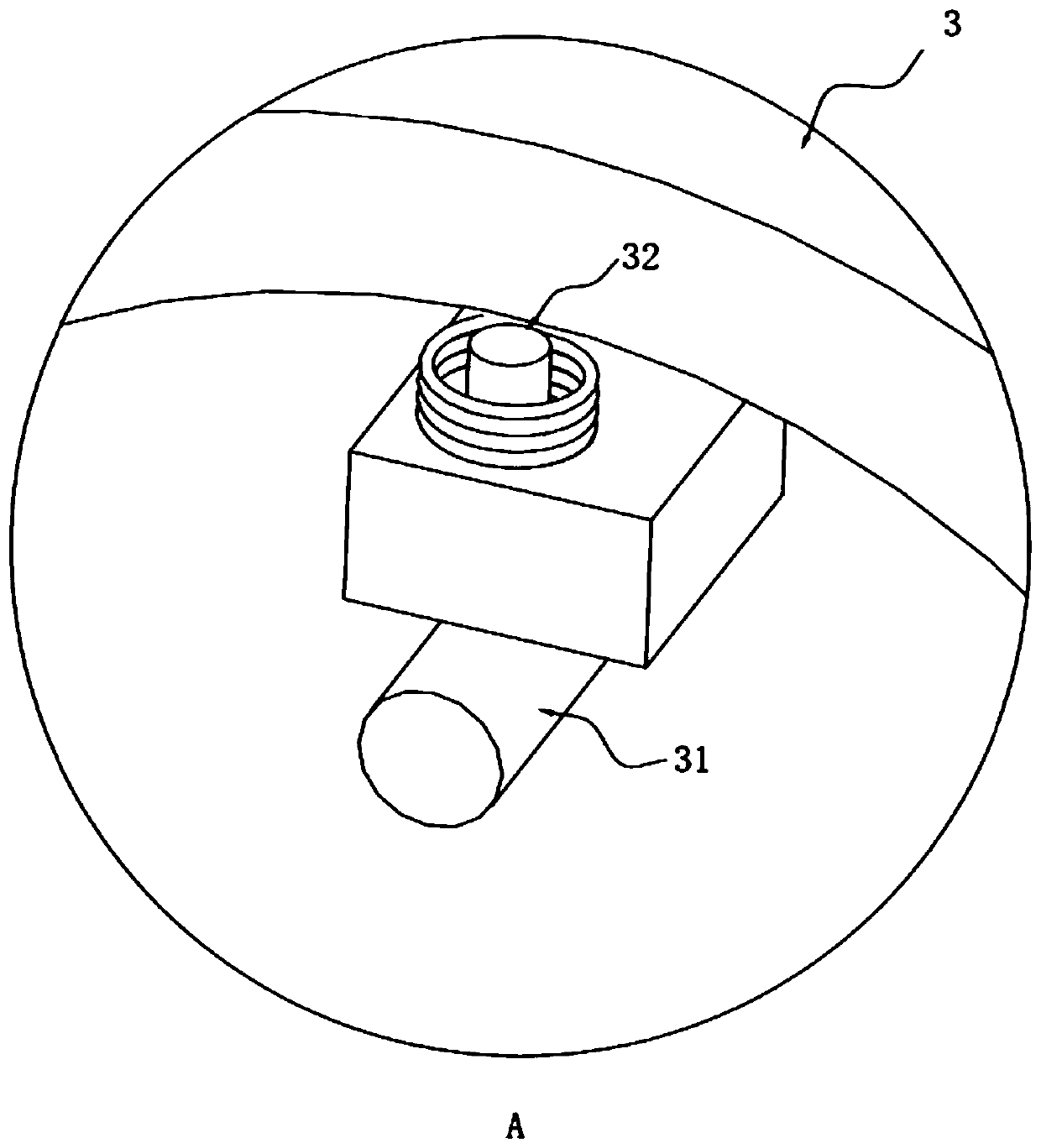

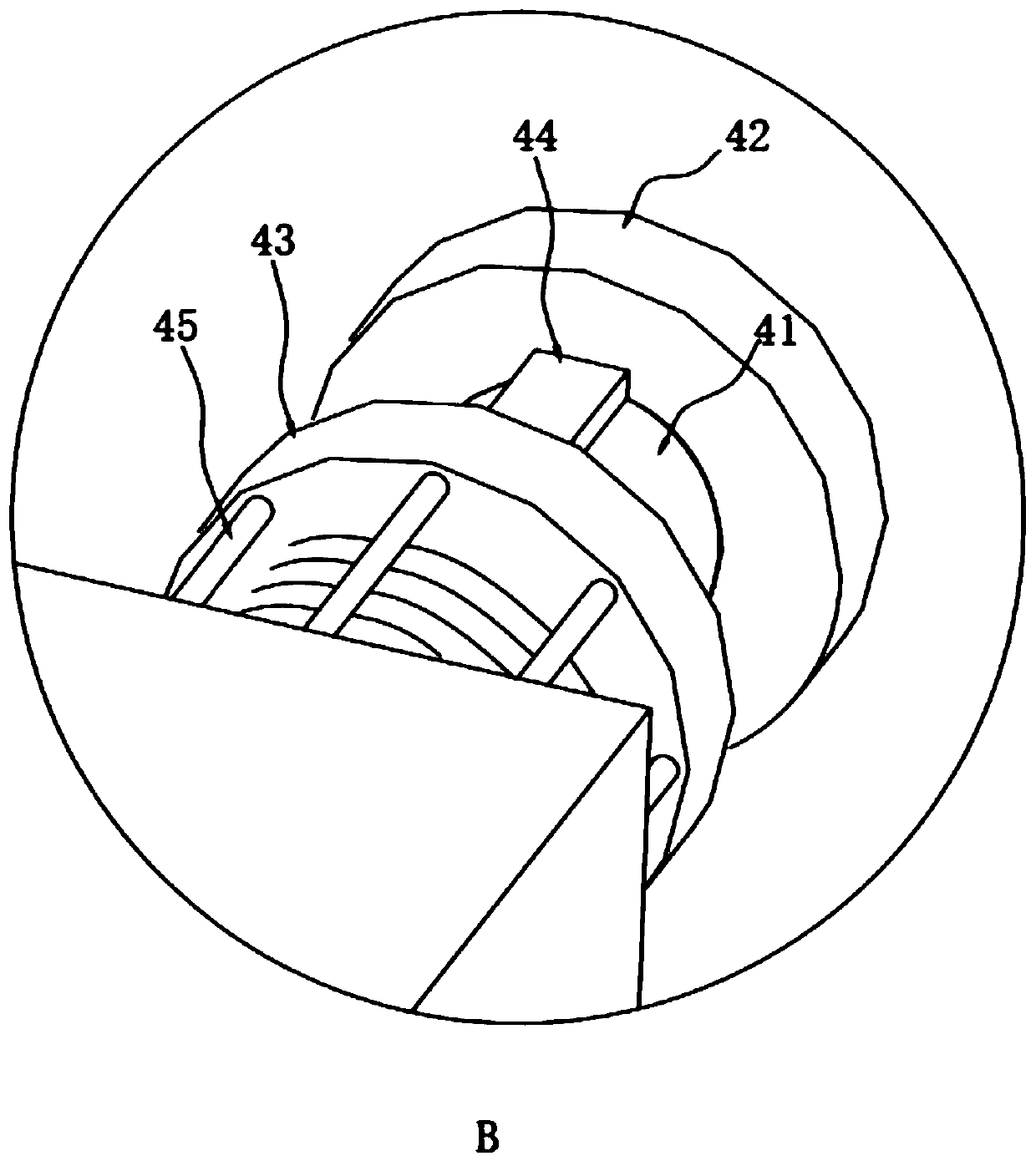

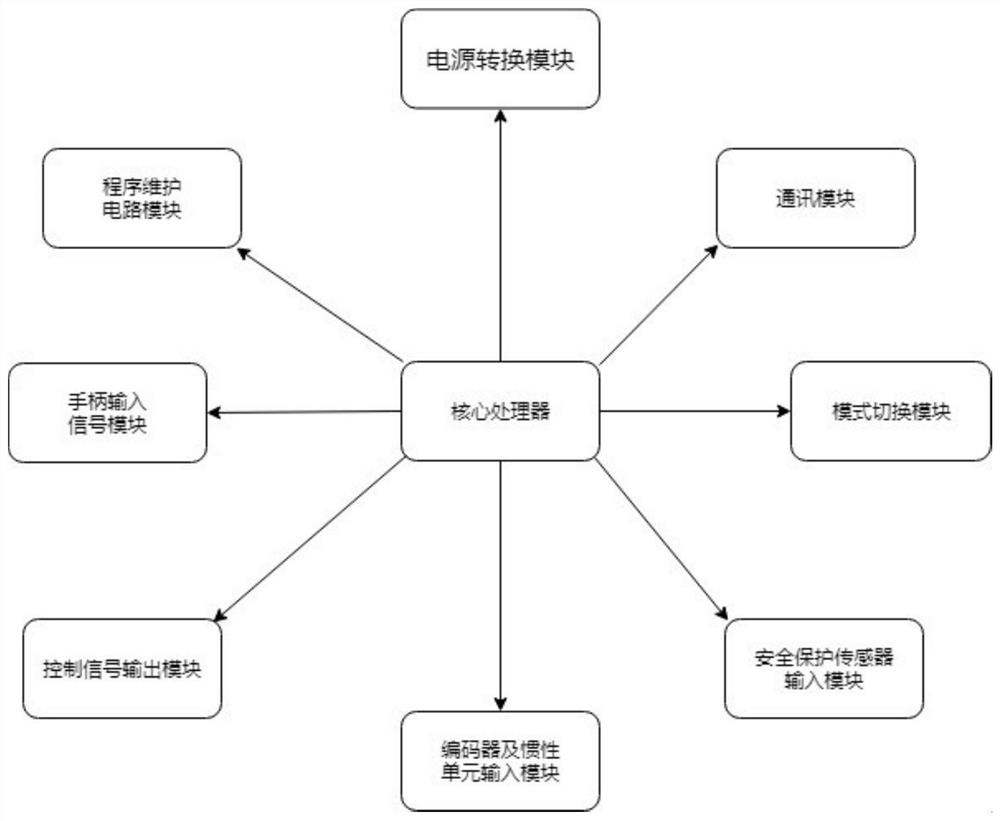

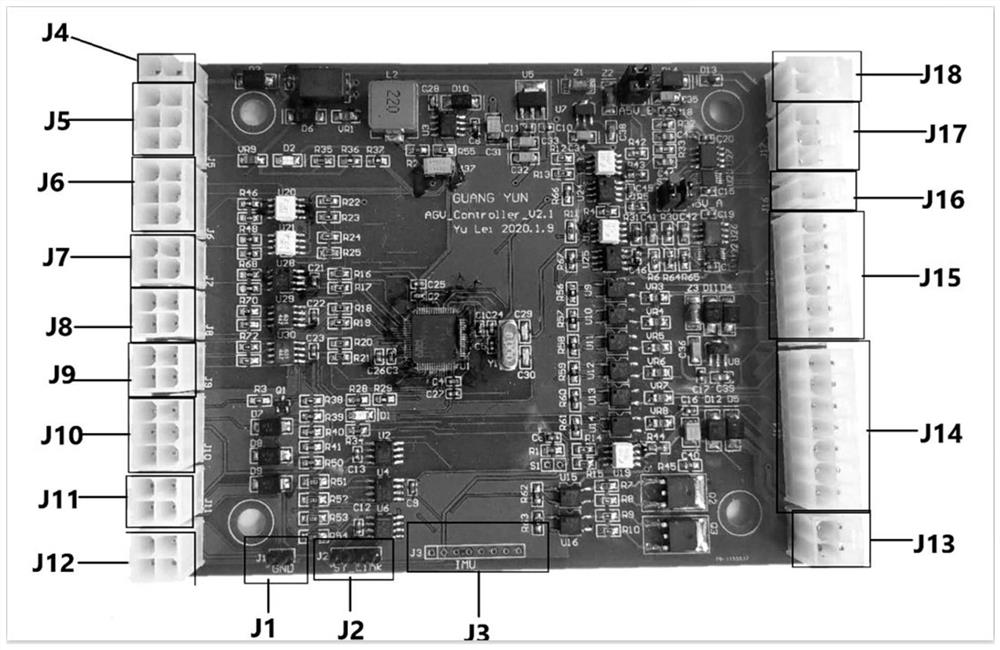

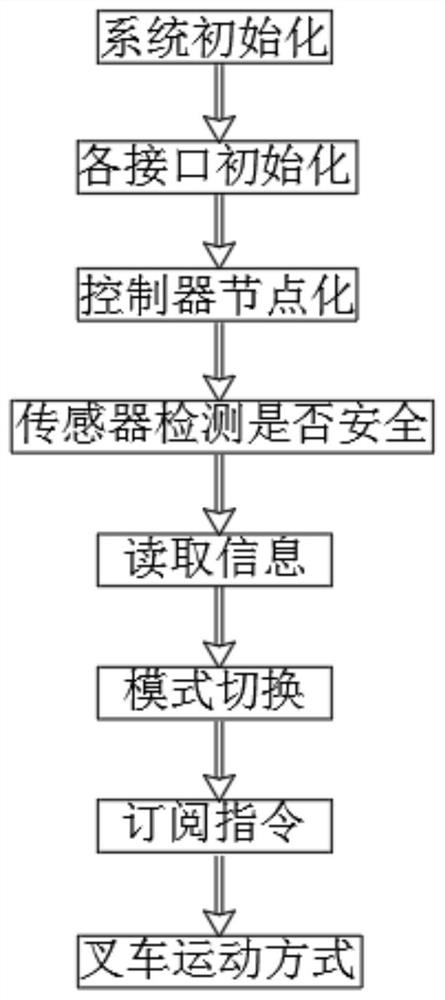

Intelligent controller for improving manual electrically-driven forklift into robot

InactiveCN112209302AReduce consumptionAchieve the purpose of transportationProgramme controlComputer controlControl signalControl engineering

The invention relates to the technical field of forklift control, and discloses an intelligent controller for improving a manual electrically-driven forklift into a robot. The intelligent controller for improving the manual electrically-driven forklift into the robot comprises a core processor, wherein the core processor is connected with a power conversion module, a communication module, a mode switching module, a safety protection sensor input module, an encoder and inertia unit input module, a control signal output module, a handle input signal module and a program maintenance circuit module. The invention further provides an intelligent control method for improving a manual electrically-driven forklift into a robot. The intelligent control method for improving the manual electrically-driven forklift into the robot comprises the following steps: S1, the system is initialized; and S2, each interface is initialized. According to the invention, an original electrically-driven forkliftwhich can only be manually controlled can be transformed into an intelligent carrying robot platform capable of being switched between a manual mode and an automatic mode, in the manual mode, the controller monitors a measurement running state, and in the automatic mode, control can be completely carried out by an upper computer, so that consumption for human resources is reduced, and the carryingefficiency is greatly increased.

Owner:青岛广运智能装备有限公司

A kind of logistics transport aquatic products transport box

ActiveCN107996489BSlow down the flowAvoid scaringPisciculture and aquariaRubber materialLogistics management

The invention relates to a logistics transportation aquatic product transportation box, and discloses a logistics transportation box device that breaks up water droplets generated by water body oscillation in the transportation box by breaking up protrusions, and reduces the beating sound when the water droplets fall back to the water surface. It is characterized in that the box cover is placed on the top of the main box, a foam pad is placed on the box cover, a through hole is opened on one side of the main box, one end of the connecting pipe is placed on the side of the main box, and it is connected to the communication hole on the side of the main box. Corresponding to the holes, the two guide rods are respectively placed on the inner walls of both sides of the main box, and the floating plate is placed in the main box. The two ends of the floating plate are respectively provided with card slots, and are respectively stuck on the two guide rods. , a plurality of airbags are respectively placed on the floating plate, the outer surface of the airbag is arc-shaped, and the outer surface of the airbag is provided with a plurality of hemispherical protrusions, the hemispherical protrusions are made of rubber material, and the floating plate An elastic pad is arranged near the side of the case cover, and a plurality of springs are built in the elastic pad, and a plurality of breaking-up protrusions are respectively placed on the elastic pad.

Owner:徐州新南湖科技有限公司

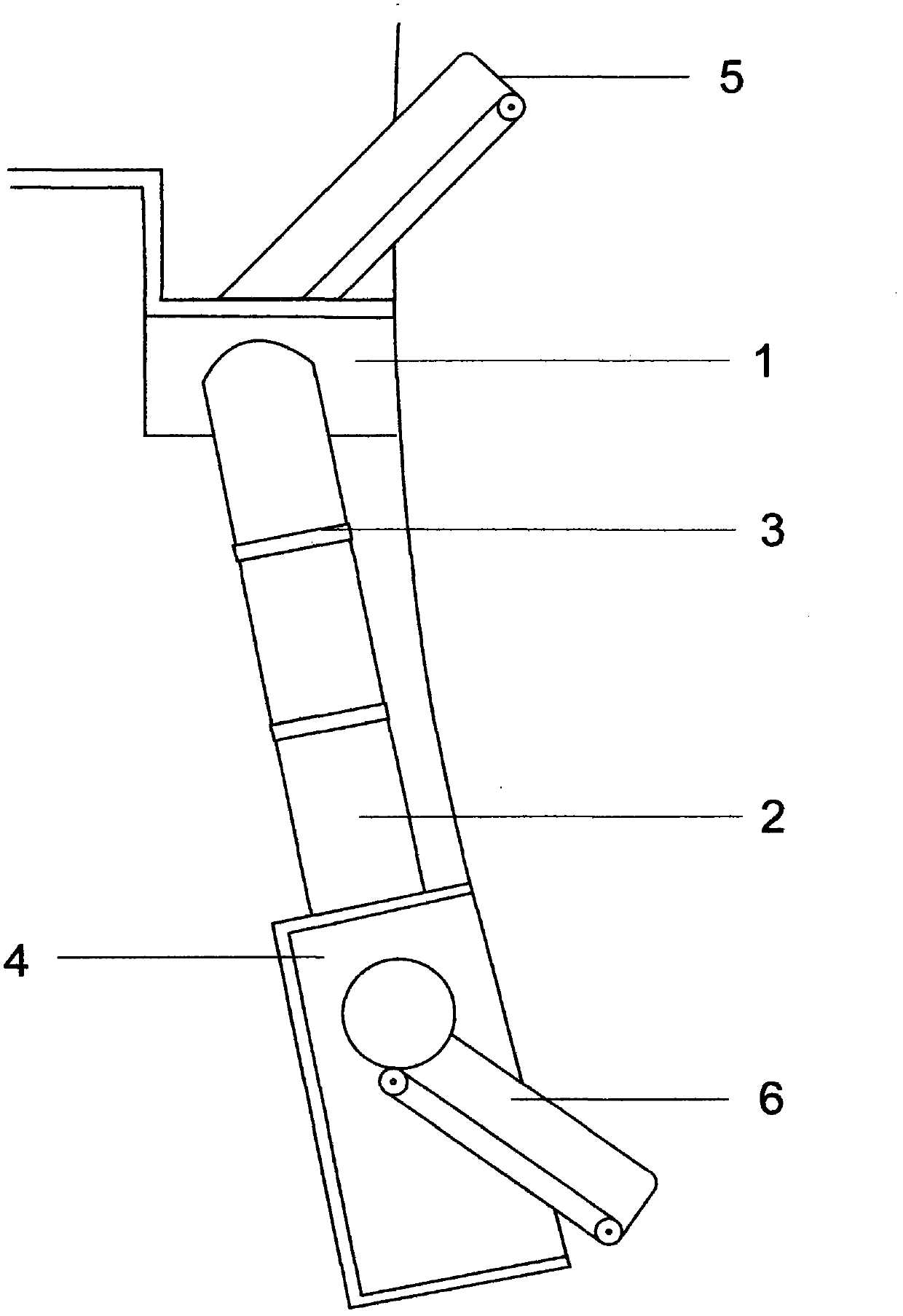

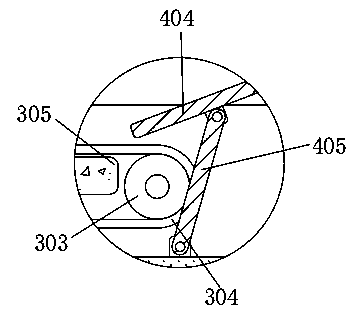

An intelligent port loading and unloading conveying equipment

ActiveCN111071704BSolve the problem of inconvenient transportationFix damageConveyorsConveyor partsElectric machineTransmission belt

The invention discloses an intelligent port loading and unloading conveying equipment, comprising a base and a concave plate, the upper surface of the base is fixed with the concave plate, and the inner sides of the left and right concave plates are installed with a transmission device. The intelligent port loading and unloading conveying equipment drives the first roller on the left side to rotate through the output shaft of the first motor, so that the first roller drives the conveyor belt to move, puts the goods on the L-shaped plate, starts the electric push rod, The push rod drives the first connecting rod to move, so that the first connecting rod drives the L-shaped plate to move, and the L-shaped plate drives the second connecting rod to move, which solves the problem that the prior art is time-consuming and increases labor. The horizontal plate drives the long rod to move, and the long rod drives the block to move, so that the block squeezes the spring, and at the same time, the long rod is reset through the elastic performance of the spring, which solves the problem that the existing technology generally has problems when handling high-altitude goods. Throwing it directly to a low place will cause damage to the goods to a certain extent.

Owner:NANJING PORT LONGTAN CONTAINER CO LTD

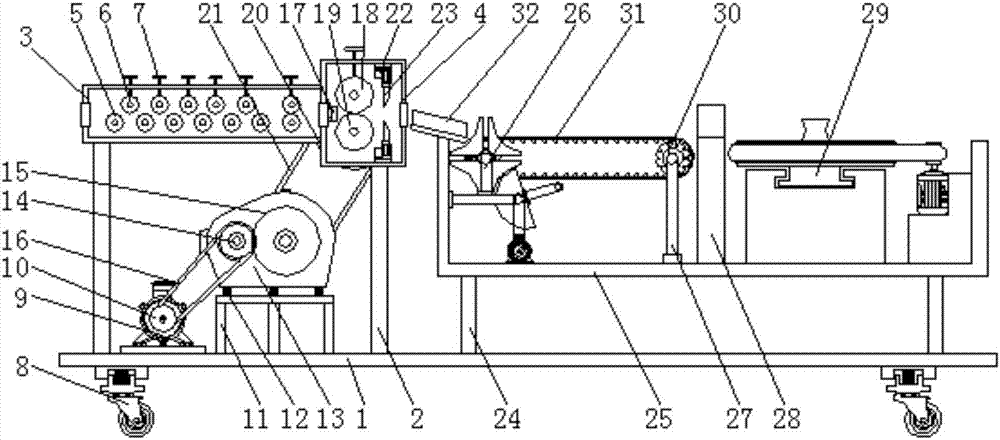

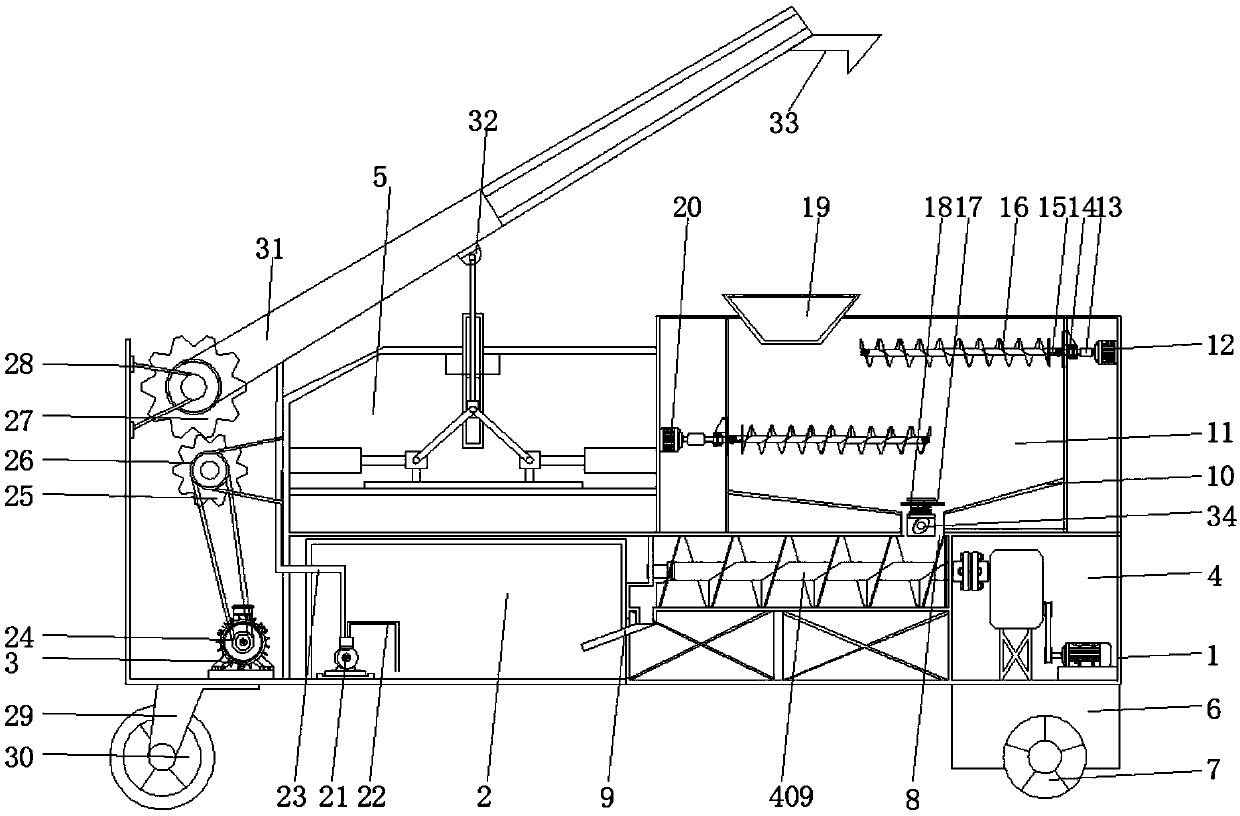

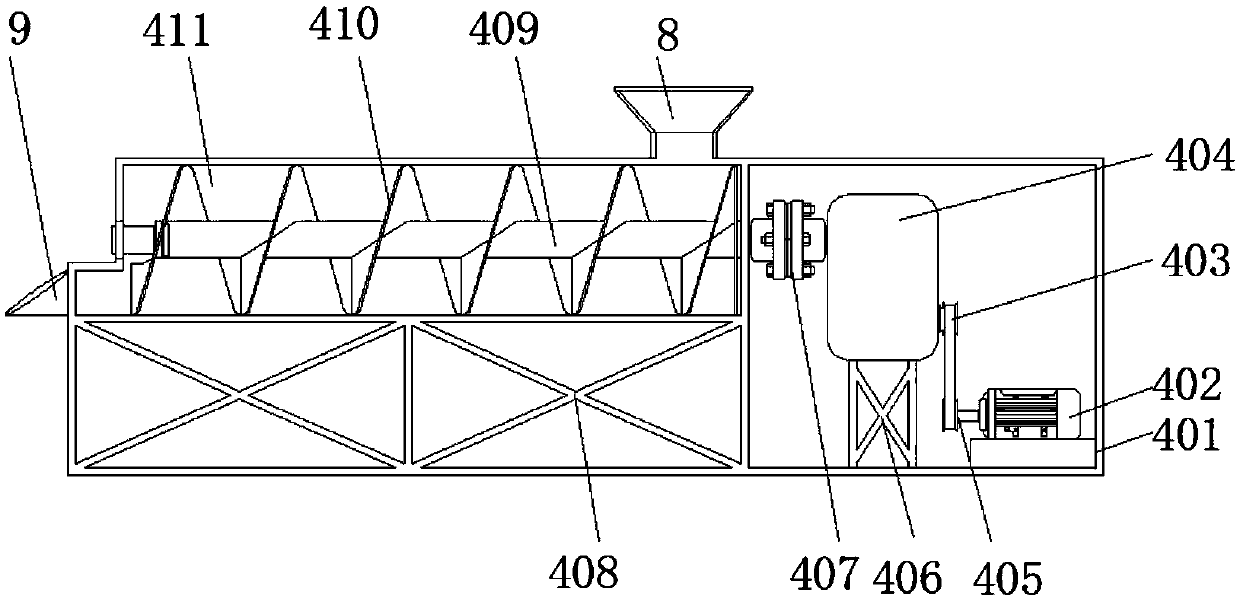

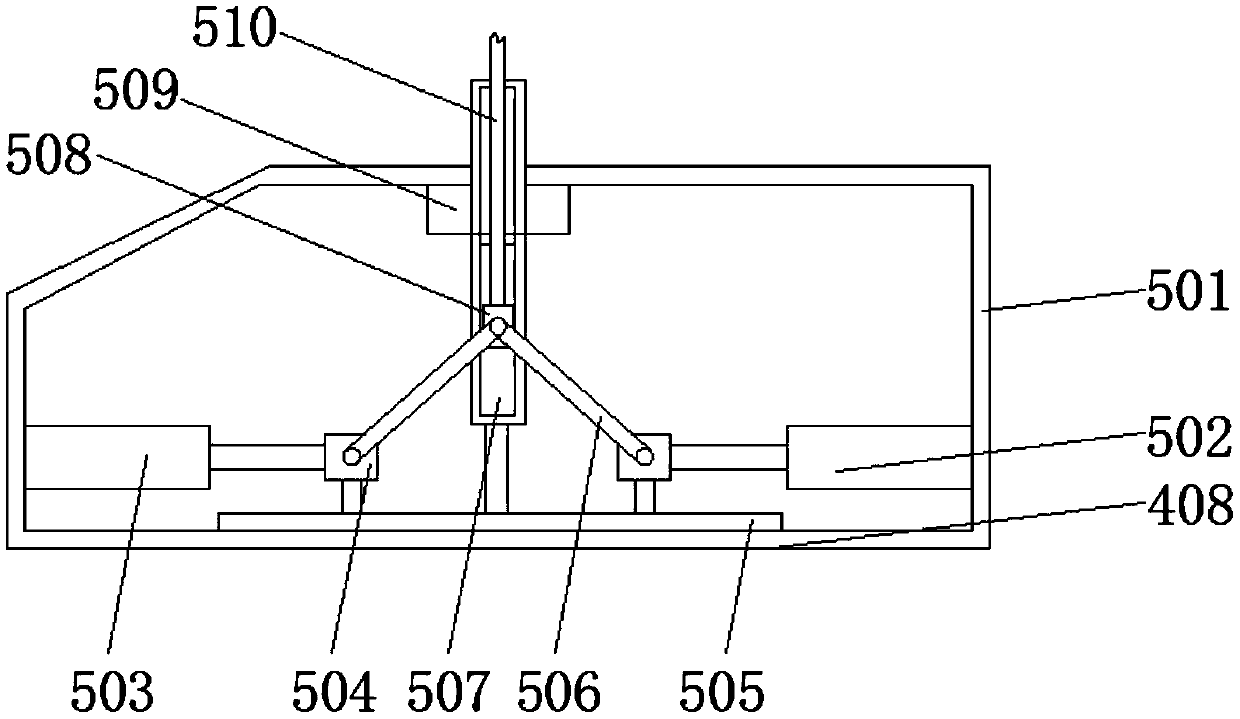

Concrete mixing conveyor for construction engineering

ActiveCN107399002BStable stirringStable deliveryDischarging apparatusCement mixing apparatusCouplingWorking environment

The invention discloses a constructional engineering concrete mixing conveyor which comprises a box. A conveying device is fixedly connected to one side of the bottom of the inner wall of the box, a mixing box is fixedly connected to the top of the outer wall of the conveying device, separating plates are arranged on the two sides of an inner cavity of the mixing box, a first motor and a second motor are fixedly connected to the two sides of the inner wall of the mixing box, output shafts of the first motor and the second motor are rotationally connected with connectors through couplers, and the ends, far away from the couplers, of the connectors are fixedly connected with mixing rotation shafts through flat keys. The constructional engineering concrete mixing conveyor relates to the technical field of conveying equipment. By means of the constructional engineering concrete mixing conveyor, concrete can be stably mixed and conveyed, the work efficiency on a construction site is improved, the number of working steps is decreased, limitation of the environment to concrete transportation and machine overall movement work is reduced, adaptability to the working environment is improved, and the working amount of workers is reduced.

Owner:上海汇辽科技发展股份有限公司

Robot equipment for assisting in large flowerpot carrying and automatic watering

InactiveCN111937640ARealize automatic wateringSimple structureSelf-acting watering devicesCultivating equipmentsSimulationMechanical engineering

The invention discloses robot equipment for assisting in large flowerpot carrying and automatic watering. The robot equipment comprises a trolley shell, a power sliding cavity is formed in the upper end in the trolley shell, a clamping cavity is formed in the trolley shell, a transmission cavity is formed in the trolley shell, and the clamping cavity is formed in the left end of the transmission cavity. The clamping cavity communicates with the transmission cavity, and the clamping cavity and the transmission cavity are at the lower end of the power sliding cavity. The robot equipment is simple in structure and easy and convenient to operate; when a large flowerpot is carried, the aim of moving the flowerpot can be achieved through cooperation of multiple persons, and manpower is wasted; atrolley is moved to the position in front of the flowerpot by being moved, the flowerpot is fixed by adjusting a clamping device, and therefore the aim of carrying is achieved; and meanwhile, in theflowerpot clamping process, automatic watering can be achieved to flowers in the flowerpot, a flowerpot base can be ejected out of the bottom, water is prevented from being exposed, and the high integration degree is achieved.

Owner:温州市渡绪春电子科技有限公司

Recycled concrete structure for road and preparation method thereof

PendingCN114717894ASolve the problem of long construction periodAchieve the purpose of transportationSolid waste managementSingle unit pavingsButt jointArchitectural engineering

The invention discloses a recycled concrete structure for a road and a preparation method thereof, and relates to the technical field of recycled concrete structures, the recycled concrete structure for the road comprises two side plates, a concrete prefabricated plate is arranged between the two side plates, and a first clamping groove is formed in the upper surface of the front end of the concrete prefabricated plate; a second clamping groove is formed in the lower surface of the rear end of the concrete prefabricated slab. Through mutual cooperation of a conical block, a hook, a fixing shaft, a movable plate, a U-shaped rod, an insertion plate, a first bolt and a second butt joint groove, a plurality of first bevel edge clamping blocks can be clamped into a plurality of first butt joint grooves, then a clamping device penetrates through a fixing through hole to be clamped into an insertion plate hole to fix a concrete prefabricated plate, and then the movable plate is rotated to fix the concrete prefabricated plate. The conical block is pulled to move into the butt joint hole, butt joint installation is completed, the problem that the construction period is long is solved through the prepared prefabricated plate, meanwhile, the structure is split, the purpose of transportation can be achieved through one transport vehicle, and the transport cost is reduced.

Owner:南宁市百荣建筑工程有限公司

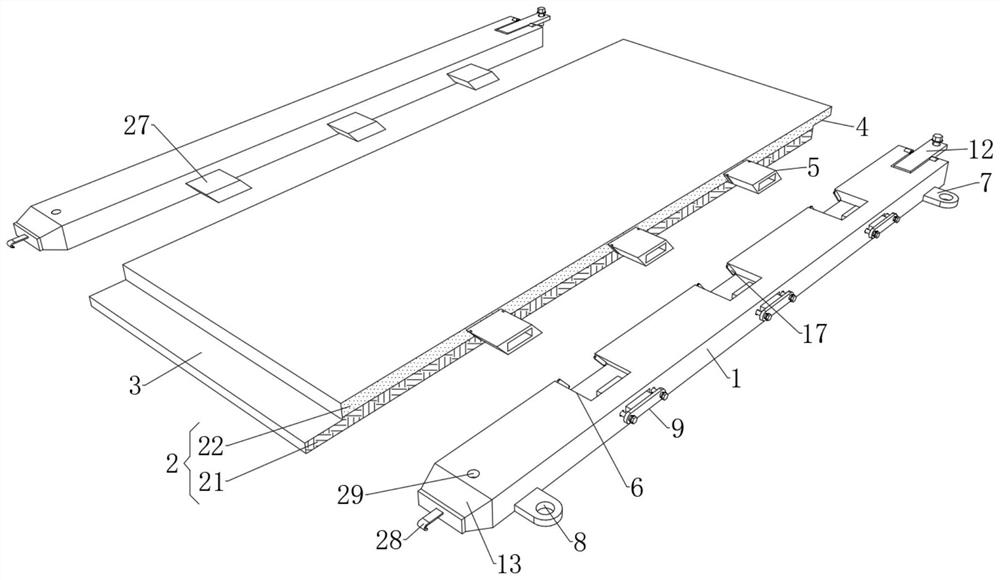

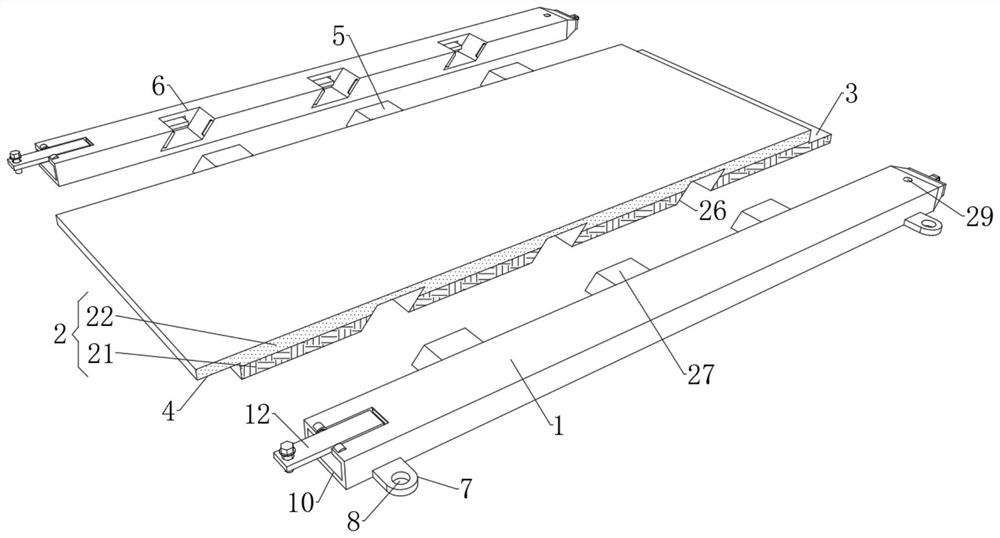

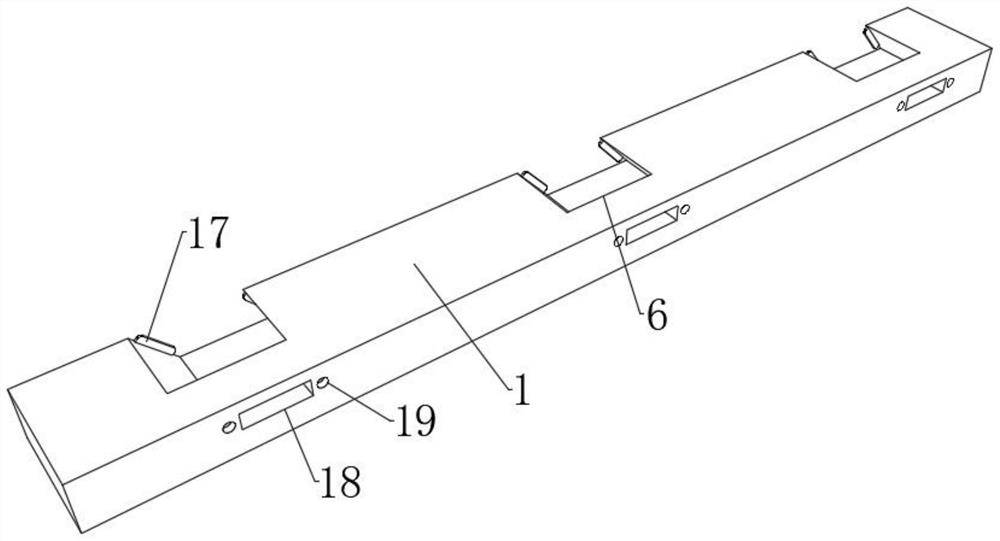

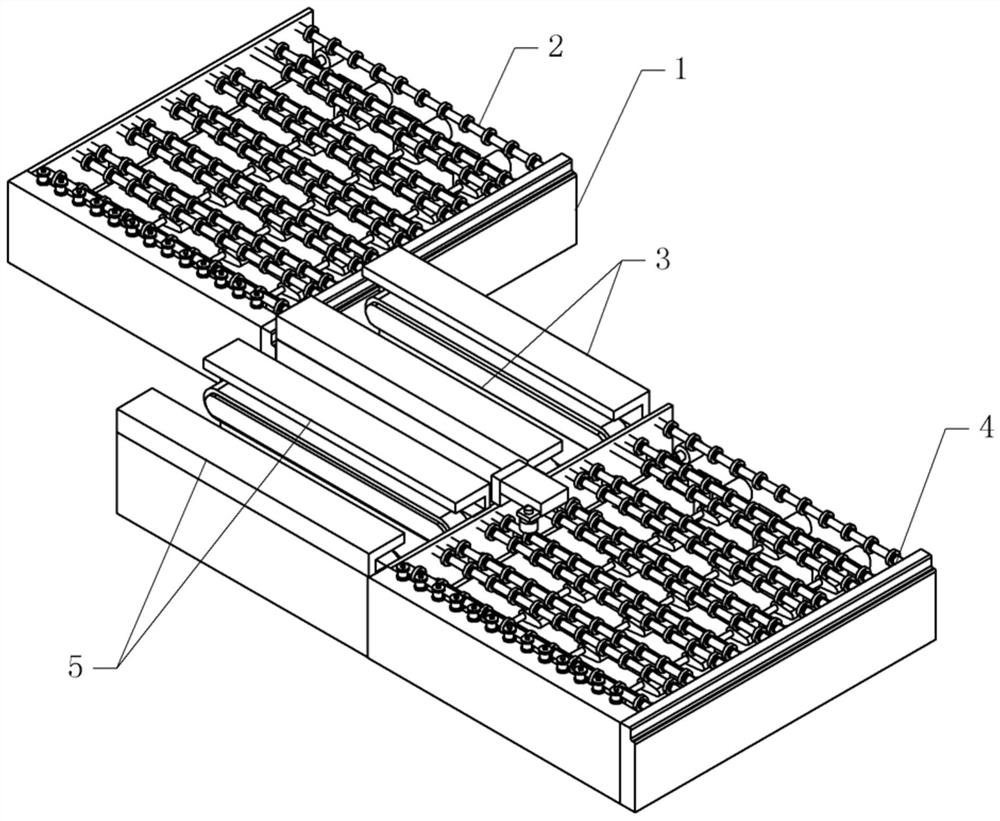

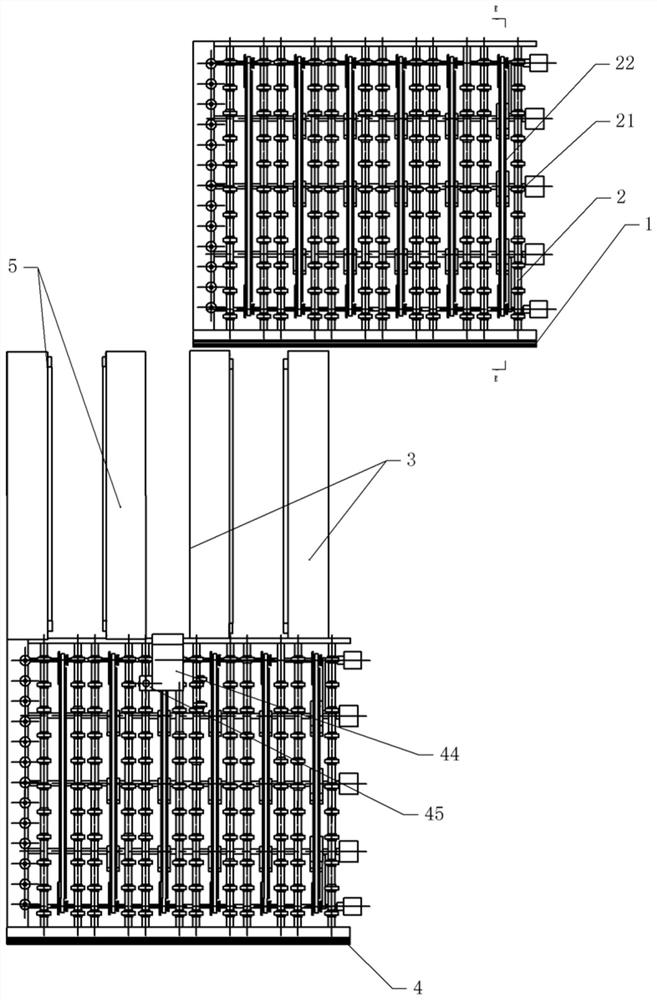

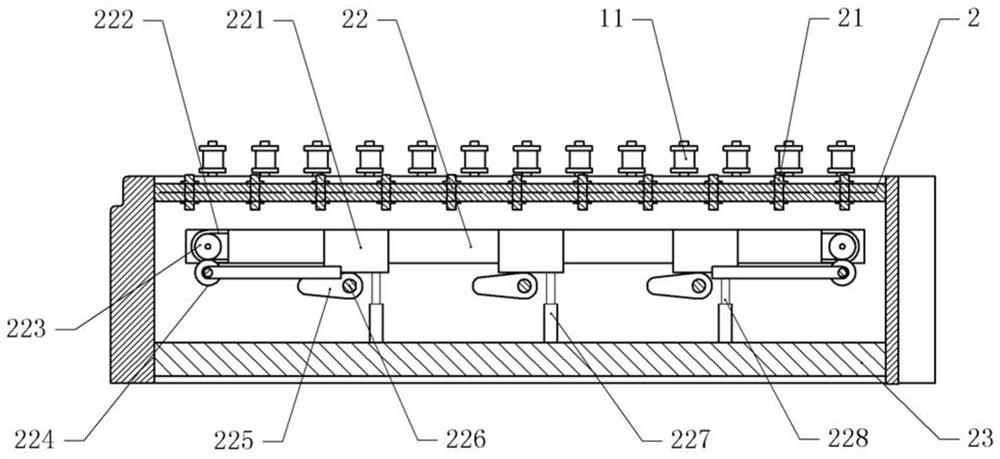

Automatic glass edging production line

InactiveCN112318272AImprove edging efficiencyLess steering workEdge grinding machinesGrinding drivesEngineeringManufacturing line

The invention relates to the technical field of glass edging, and discloses an automatic glass edging production line. The automatic glass edging production line comprises a rack, wherein a first conveying mechanism and a second conveying mechanism are arranged on the rack, each of the first conveying mechanism and the second conveying mechanism comprises a roller conveying mechanism and a plurality of belt conveying mechanisms, and the belt conveying mechanisms and the roller conveying mechanisms are arranged in a staggered mode; first bilateral edging devices are arranged at the tail ends ofthe belt conveying mechanisms in the conveying direction, the second conveying mechanism is located at the tail ends of the first bilateral edging devices in the conveying direction, and a second bilateral edging device is arranged at the tail end of the second conveying mechanism in the conveying direction; driving mechanisms for driving the roller conveying mechanisms are arranged below the roller conveying mechanisms, and lifting mechanisms for lifting the belt conveying mechanisms are arranged below the belt conveying mechanisms; and a steering mechanism is arranged on the side, close tothe first bilateral edging device, of the second conveying mechanism. The automatic glass edging production line has the advantages of being simple in structure and capable of edging glass efficiently.

Owner:CHONGQING CONGBO ENERGY SAVING GLASS CO LTD

An eye flushing device for ophthalmic treatment that is convenient for cleaning and disinfection

ActiveCN112618335BQuick releaseRapid cleaning and disinfectionBathing devicesEye treatmentOphthalmologyWastewater

The invention discloses an eye flushing device for ophthalmic treatment which is convenient for cleaning and disinfection, which comprises a support seat, the upper surface of the support seat is fixedly connected with a waste water collector, and the outer surface of the waste water collector is provided with a drain port, so The outer surface of the wastewater collector is slidably connected with a moving frame, and the upper surface of the moving frame is fixedly connected with a drainage groove, and the inside of the drainage groove is fixedly connected with a first water delivery pipe. The eye flushing device for ophthalmic treatment that is convenient for cleaning and disinfection can quickly disassemble the upper protective shell, so that the water outlet and the protective shell can be quickly disinfected and cleaned, and the height of the water outlet can be changed, so that It is suitable for people of different heights, and the pulleys can be retracted, so that the device can be transported conveniently and can also be stable during use.

Owner:江门五邑爱尔新希望眼科医院有限公司

A municipal engineering environmental sanitation garbage bin transport frame

ActiveCN108033093BCause damageReduce physical exertionRigid containersInternal fittingsAgricultural engineeringStructural engineering

The invention provides a municipal engineering environmental sanitation garbage can carrying frame. The frame is used in cooperation with an electric tricycle. Five garbage cans are carried at the same time, and the carrying frame can be used for carrying and unloading on the garbage cans. The five garbage cans are carried at the same time, the carrying efficiency of the garbage cans is greatly improved, the garbage can is convenient and fast to assemble and disassemble, and the physical consumption of the sanitation workers is reduced. The carrying frame is characterized in that one ends of the four vertical rods are vertically arranged on a fixed plate, and are positioned at four corners of the fixed plate; the fixed plate is in a cuboid shape, a magnet is arranged at the bottom of the fixing plate, and two of the four vertical rods are in a group; the other ends of the two vertical rods in the same group are connected through sliding rods, and the two sliding rods are parallel to each other; and a plurality of clamping rings are arranged on the sliding rods in a sleeved mode and are fixed through bolts, one ends of the connecting rods are connected with the clamping rings, fixing rings are arranged at the other ends of the connecting rods, and the other ends of the two vertical rods on the front side are connected through a limiting rod.

Owner:XUZHOU CHUANGZHISHE GENERAL TECH IND RES INST CO LTD

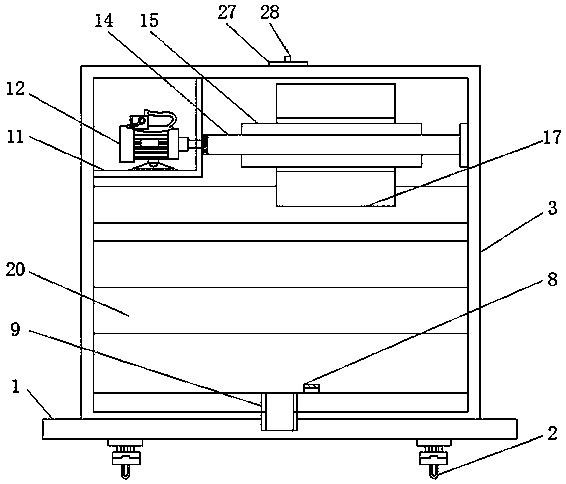

Mixing device with weighing functionfor straw edible fungus processing

InactiveCN110624489AAchieve the purpose of transportationAchieve the purpose of weighingChemical/physical/physico-chemical stationary reactorsFeed devicesAgricultural engineeringPulley

The invention relates to the technical field of straw edible fungus processing, and discloses a mixing device with aweighing functionfor straw edible fungus processing. The mixing device comprises a main box and a reaction box, wherein the bottom wall of the inner cavity of the main box is fixedly connected with a first motor, the output shaft of the first motor is fixedly connected with a first helical gear, the rear part of the main box is fixedly connected with a gear box, and a third helical gear consists of a rotating gear at the bottom and a conveying wheel at the top. The mixing devicewith the weighing functionfor straw edible fungus processing provides power for operation of the device by arrangingthe first motor at the top of the main box, the first helical gear is arranged at the output shaft of the first motor to mesh with asecond helical gear, so that adriving gear and adriven gear outside the second helical gear rotate afirst rotating rod, and the rotation of the first rotating rod and adriving pulley is arranged, so that the rotation of aconveyor belt outside the driving pulley achieves the purpose of transportation.

Owner:安徽硒菇食品科技有限公司

Constructional engineering concrete mixing conveyor

ActiveCN107399002AStable stirringStable deliveryDischarging apparatusCement mixing apparatusCouplingArchitectural engineering

The invention discloses a constructional engineering concrete mixing conveyor which comprises a box. A conveying device is fixedly connected to one side of the bottom of the inner wall of the box, a mixing box is fixedly connected to the top of the outer wall of the conveying device, separating plates are arranged on the two sides of an inner cavity of the mixing box, a first motor and a second motor are fixedly connected to the two sides of the inner wall of the mixing box, output shafts of the first motor and the second motor are rotationally connected with connectors through couplers, and the ends, far away from the couplers, of the connectors are fixedly connected with mixing rotation shafts through flat keys. The constructional engineering concrete mixing conveyor relates to the technical field of conveying equipment. By means of the constructional engineering concrete mixing conveyor, concrete can be stably mixed and conveyed, the work efficiency on a construction site is improved, the number of working steps is decreased, limitation of the environment to concrete transportation and machine overall movement work is reduced, adaptability to the working environment is improved, and the working amount of workers is reduced.

Owner:上海汇辽科技发展股份有限公司

Method and device of reaction cup movement path control

ActiveCN109142772APrevent fallingAvoid squeezingMaterial analysisControl flowBiochemical engineering

The invention provides a method and device of reaction cup movement path control, wherein the method comprises the following steps: in response to a demand of adding a reaction cup, the reaction cup pusher is controlled by a controller to move to a second ultimate limit state, so that a blocking part of a cup body of the reaction cup pusher is relieved from blocking a first reaction cup positionedat a waiting station, the first reaction cup positioned at the waiting station enters a cup body guiding channel of the reaction cup pusher, the controller controls the reaction cup pusher to move toa first ultimate limit state, the cup guiding channel is communicated with the next station, so that the first reaction cup entering the guiding channel of the cup body is conveyed to the next station, the reaction cup next to the first reaction cup arranged in a conveying trough of the reaction cup into the waiting station, and the reaction cup entering the waiting position is blocked at the waiting station by the blocking part of the cup. By the method, only one reaction cup can be transported from the waiting station to the next station at one time, and the control flow of the component atthe next station can be simplified.

Owner:MACCURA MEDICAL INSTR CO LTD

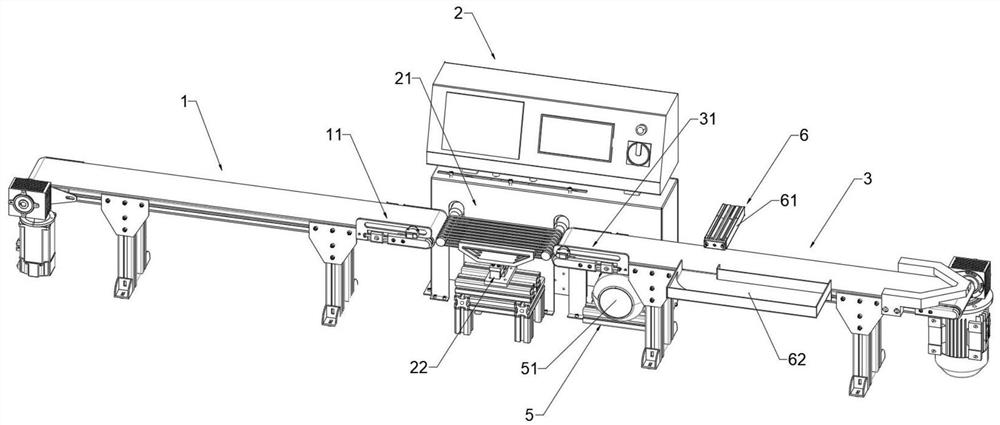

Intelligent metering detection equipment

PendingCN114739495AImprove accuracyReliable entryWeighing apparatus using elastically-deformable membersWeighing apparatus detailsControl engineeringAutomation

The invention discloses intelligent metering detection equipment, and relates to the technical field of metering detection, the intelligent metering detection equipment comprises a left conveying assembly, a metering detection assembly and a right conveying assembly, the left conveying assembly comprises an outlet structure, the right conveying assembly comprises an inlet structure, the metering detection assembly comprises a conveying table structure, and a metering detection structure is arranged below the conveying table structure; the conveying table structure comprises a first rotating part, a second rotating part and a conveying ring set, a conveying face is formed on the top face of the conveying ring set, and the first rotating part and the second rotating part are connected with a lifting assembly and a rotating assembly. The metering detection structure comprises a supporting table, the top of the supporting table extends into the conveying ring set between the first rotating part and the second rotating part, a weighing face is formed on the top face of the supporting table, and a weighing sensor is arranged at the bottom of the installation body. The device has the advantages of being high in automation degree, accurate in metering detection result and high in metering detection efficiency.

Owner:刘永东

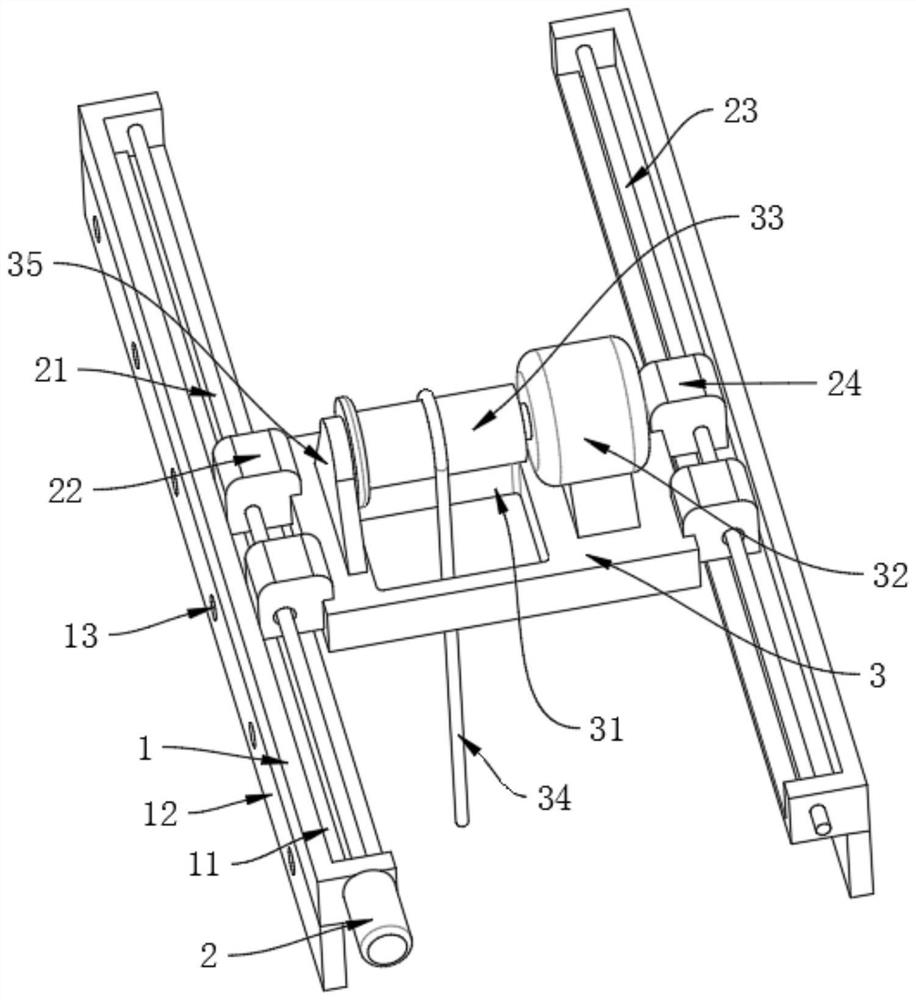

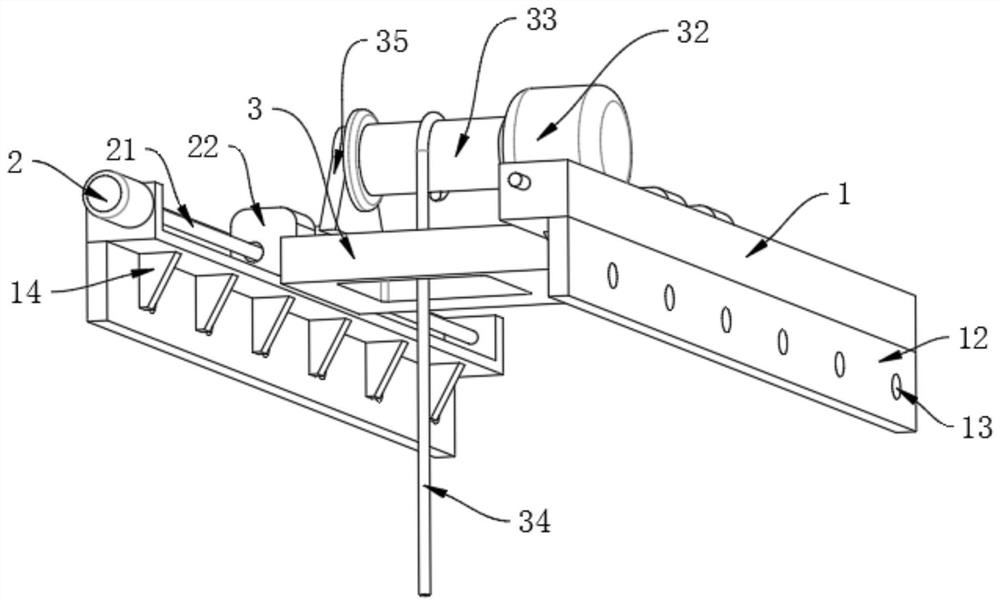

Lifting appliance applied to vehicle machining

PendingCN114044439AAchieve the purpose of transportationGuaranteed stabilityWinding mechanismsTravelling gearElectric machineryEngineering

The invention provides a lifting appliance applied to vehicle machining, and relates to the technical field of vehicle machining. The lifting appliance comprises two symmetrically arranged sliding frames, each sliding frame comprises a sliding seat, and the upper surface of each sliding seat is provided with a sliding groove; the lower surface of each sliding seat is fixedly connected with a fixing plate, the outer surface of each fixing plate is uniformly provided with a plurality of connecting holes, and reinforcing ribs are fixedly connected to the inner surface of the fixing plate and are fixedly connected with the bottom of the sliding seat, wherein a first motor is fixedly connected to the outer surface of the sliding frame. The two sliding frames are arranged, the sliding grooves are formed in the sliding seats, then the first motor is started to drive the threaded rods to rotate, and therefore the first sliding blocks are driven to slide along the sliding grooves and cooperate with the second sliding blocks to slide along the sliding rods, so that the fixing seats are driven to slide, and the purpose of transportation is achieved; and a second motor is cooperatively started to drive a rotating cylinder to rotate, so that a bottom pull rope is driven to ascend and descend, and the lifting work is completed.

Owner:HEFEI CHANGQING MACHINERY

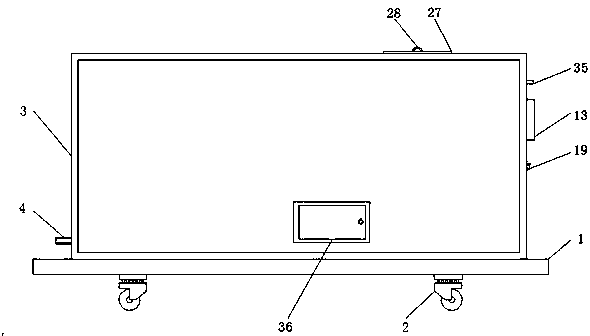

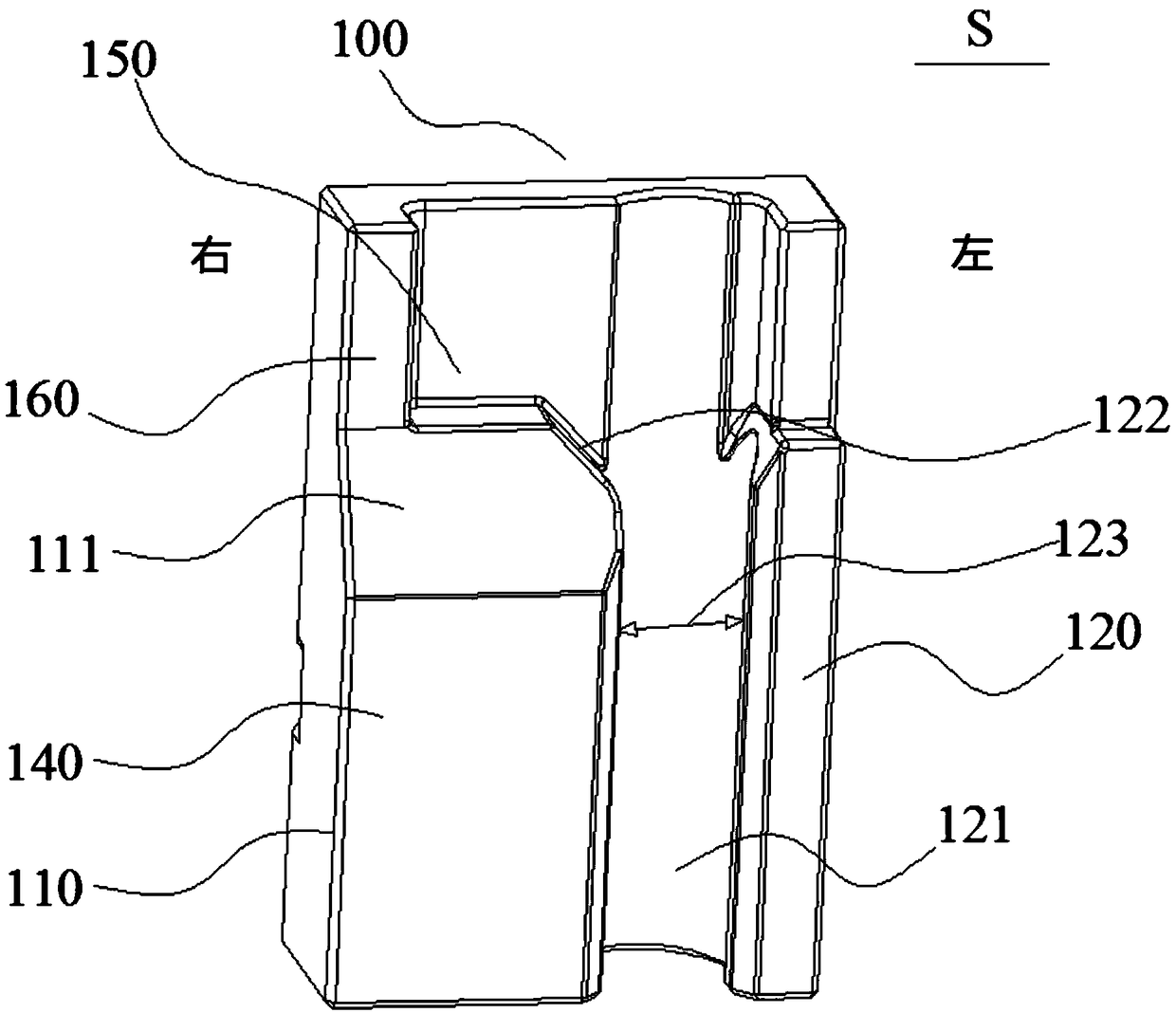

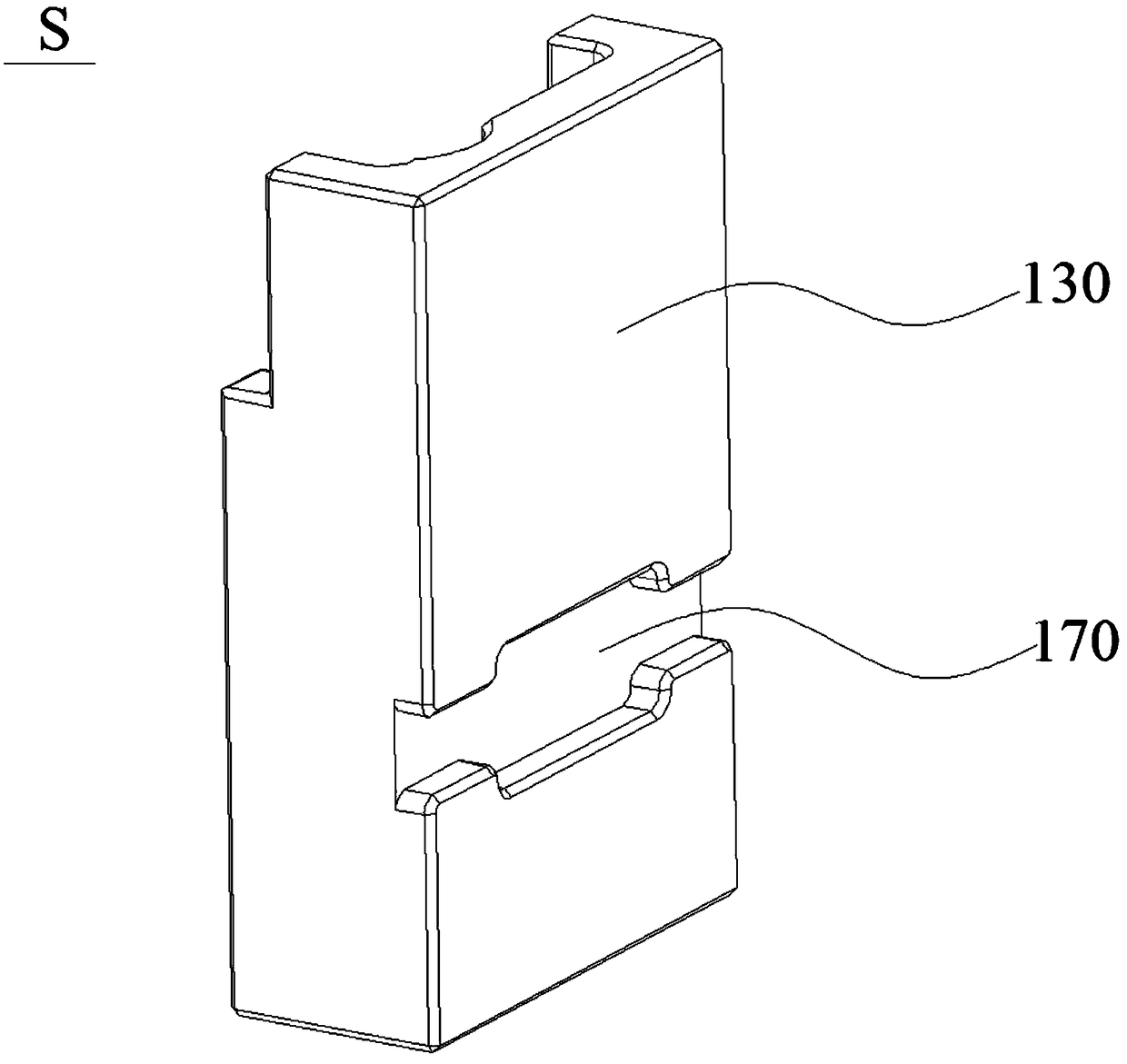

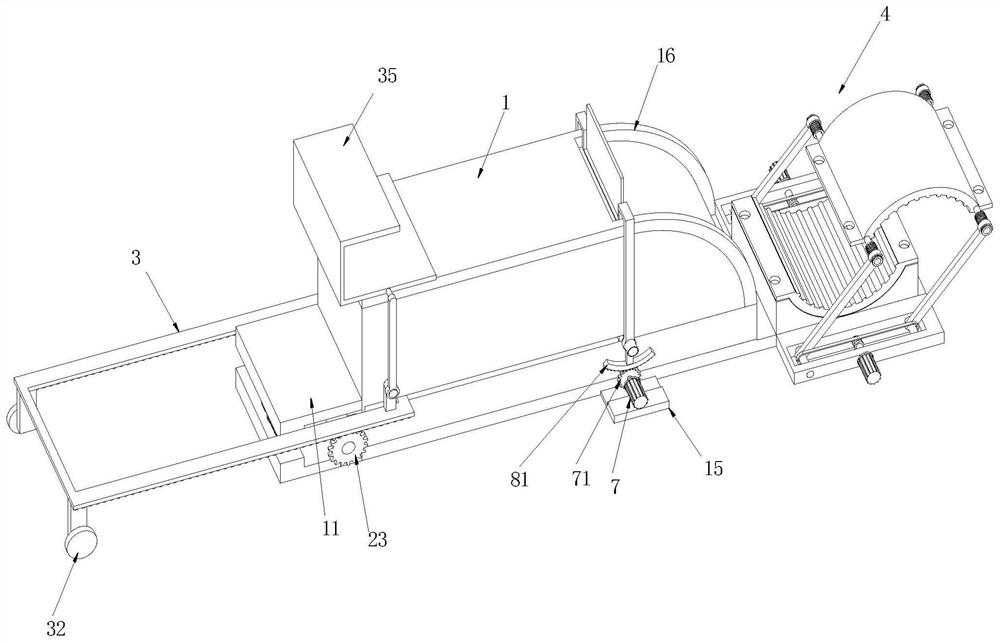

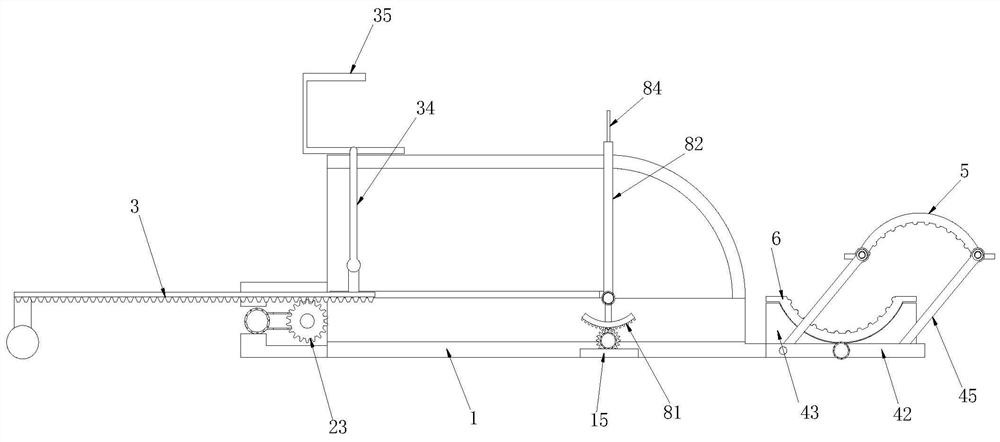

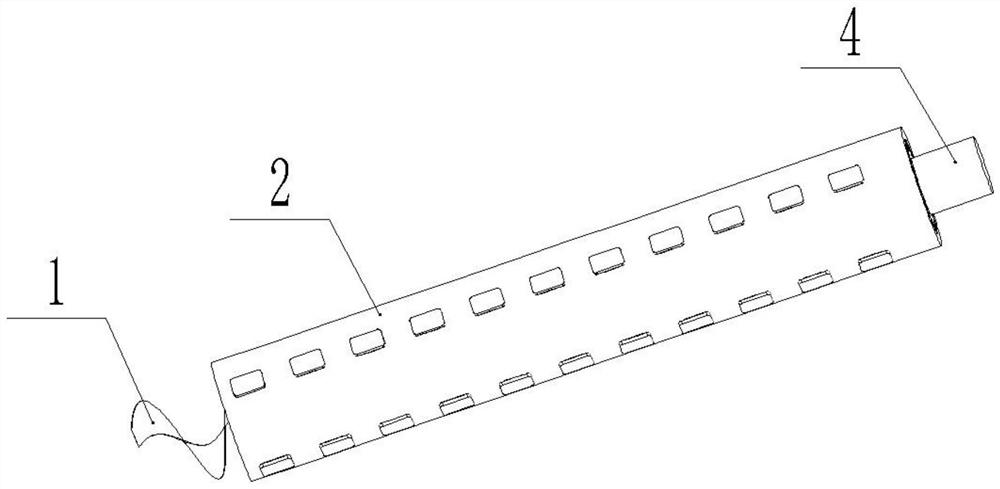

A kind of eps protective structure for washing machine tub

ActiveCN110396799BImprove efficiency in installing protective structuresAchieve the purpose of transportationOther washing machinesTextiles and paperLaundry washing machineStructural engineering

The invention discloses an EPS protection structure for a washing machine tub. The EPS protection structure comprises an installing frame, a driving frame, a protecting device, protecting plates and aswinging device. The driving frame is movably installed on the installing frame. A driving device is arranged on the installing frame and connected with the driving frame. An arc-shaped frame is installed at the tail end of the installing frame. The washing machine tub moves along with the driving frame so as to be conveyed on a platform without colliding with the outside world in the whole process, the conveying process is smooth and steady, and the efficiency of installing the protection structure on the washing machine tub is improved; in the whole process, the washing machine tub can be moved from a high place to a low place and has a certain initial speed after being moved to the low place so as to be rapidly clamped between the upper and lower adjacent protecting plates and conveniently and rapidly installed; when the washing machine tub is conveyed to the outside world, deformation is avoided; the protection structure is convenient and simple to install and detach and can be repeatedly used; compared with the prior art, the EPS protection structure avoids resource waste and responds to the energy conservation and emission reduction slogan.

Owner:安徽艾普塑料科技有限公司

A screw conveyor with variable pitch

ActiveCN112173601BAchieve the purpose of transportationImprove support strengthPackagingHelical bladeCrushed stone

The invention relates to a conveyor for transporting muck, in particular to a screw conveyor with variable pitch, comprising: a screw input end, an outer cylinder, and an inner cylinder; the inner cylinder is cylindrical and fixed on the outer cylinder in sections There are external splines on the cylinder and the outer wall of the inner cylinder to cooperate with the internal splines on the outer cylinder, and then the rotation of the outer cylinder can drive the inner cylinder to rotate together; the invention fixes the spiral blade of the screw conveyor on the shell, and drives the shell during transportation Rotate, and then drive the spiral blades to rotate to achieve the purpose of transportation, so that the support strength has been significantly improved; the inner cylinder of the screw conveyor provided by the present invention is a segmented unit body, and multiple are fixed on the outer cylinder, and the inner cylinder is relative to the outer cylinder. The barrel can move back and forth, so that the pitch of the helical blade will change dynamically with the size of the gravel, so that there is no worry about the gravel that can enter the pipeline and will be stuck.

Owner:安徽唐兴装备科技股份有限公司

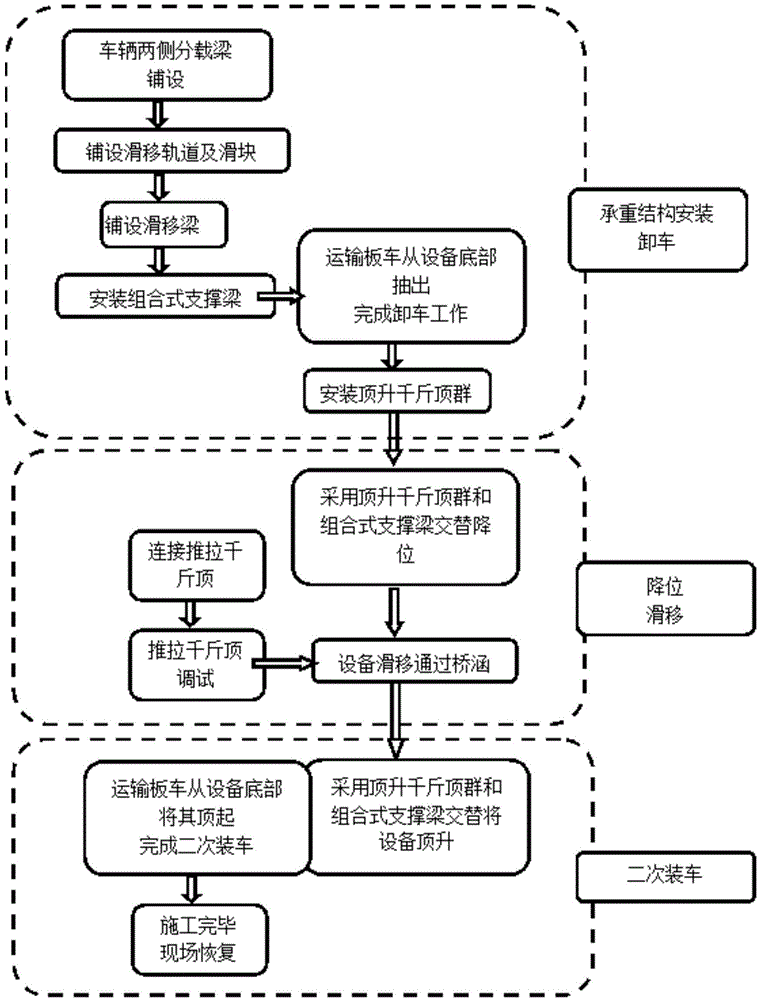

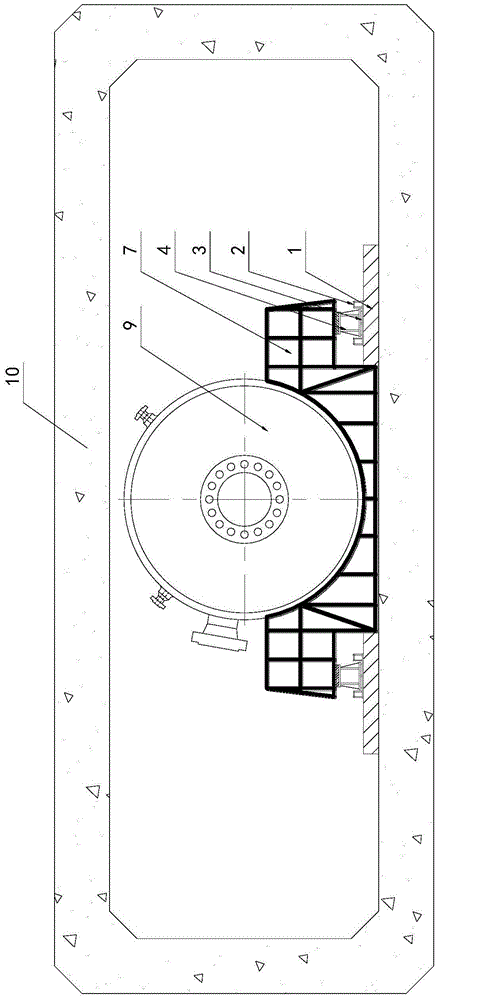

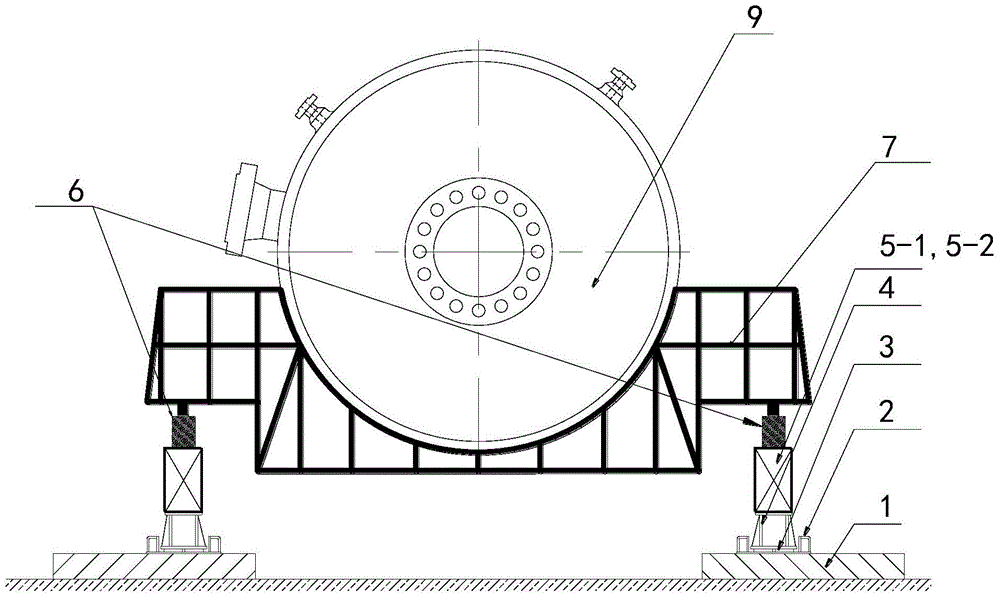

Extremely low-level transportation of super-high and large-scale equipment across bridges and culverts

ActiveCN103253176BReduce coefficient of frictionReduced sliding resistanceItem transportation vehiclesPush and pullPolytetrafluoroethylene

The invention discloses a construction method for transporting ultrahigh large-scale equipment to pass through a bridge and culvert in an extreme low location. The ultrahigh large-scale equipment is fixed on a transporting plate trailer with the adoption of a stepped transporting saddle. The construction method comprises a first step of installation of a bearing structure, a second step of unloading, a third step of location lowering, a fourth step of sliding and a fifth step of secondary loading. The first step further comprises the following steps of (1) paving load parting beams, (2) paving sliding tracks on the load parting beams, and paving teflon blocks in the sliding tracks, (3) paving sliding beams on the teflon blocks. The second step further comprises the flowing steps of (1) installing a combined type bearing supporting beam on the sliding beams, (2) using the combined type bearing supporting beam for supporting the stepped transporting saddle. The third step further comprises the following step of using the method that a sync jack-up jack group and the combined type bearing supporting beam are alternately lowered, and lowering the stepped transporting saddle onto the sliding beams, wherein the stepped transporting saddle tightly attaches to the ground at the moment. The fourth step further comprises the following step: using a push-and-pull jack to drive the sliding beams to move forwards until the equipment is completely moved out of the bridge and culvert. According to the construction method for transporting the ultrahigh large-scale equipment to pass through the bridge and culvert in the extreme low location, the ultrahigh large-scale equipment can pass through the bridge and culvert in the extreme low location, and the purpose of transportation is achieved.

Owner:SINOPEC THE FOURTH CONSTR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com