Extremely low-level transportation of super-high and large-scale equipment across bridges and culverts

A large-scale equipment and low-level technology, which is applied in the field of ultra-high and large-scale equipment crossing bridges and culverts at extreme low positions, can solve the problems of on-site welding quality, overall transportation, and welding quality, and achieve continuous preparation time and implementation time. , The friction coefficient is small, the effect of reducing the sliding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

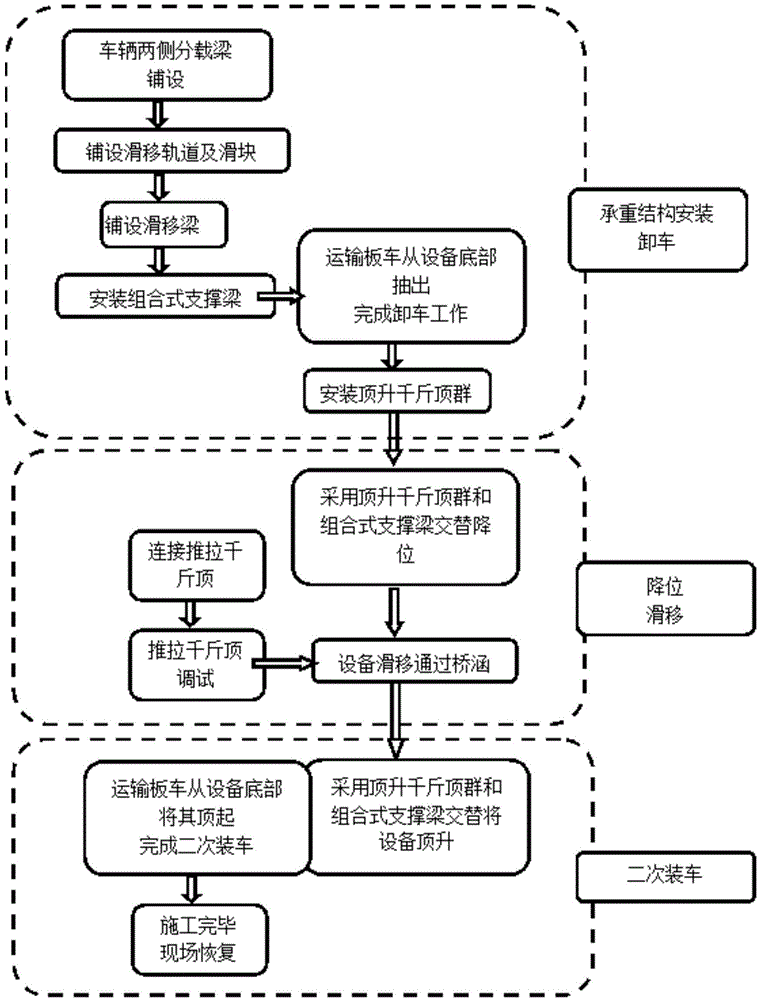

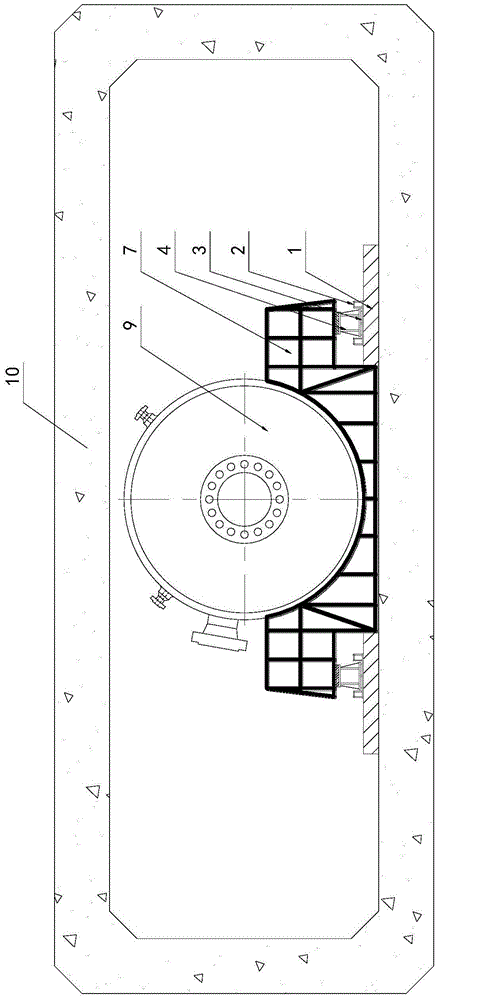

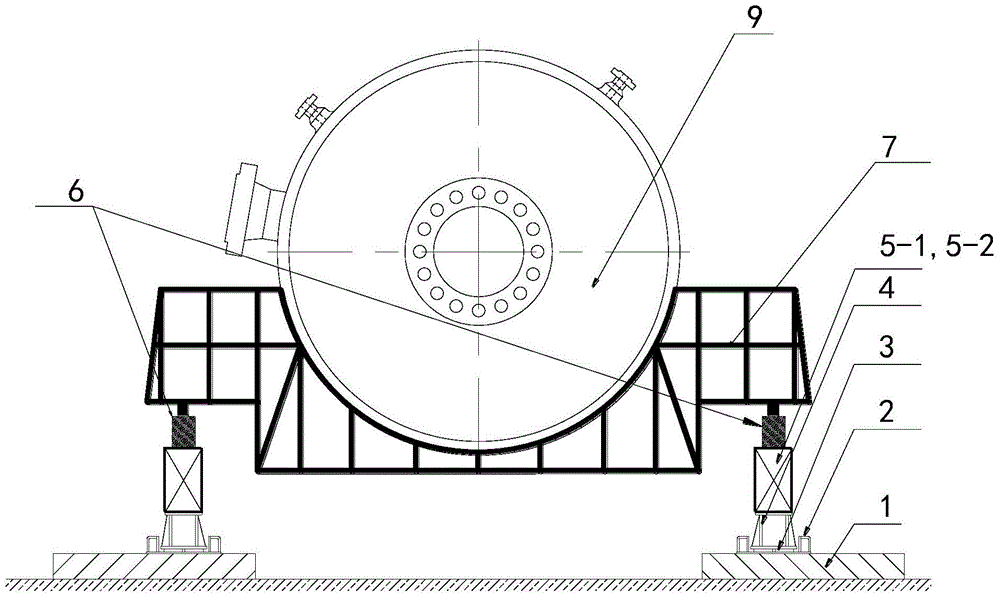

[0050] see Figure 1 to Figure 15 , a construction method for extremely low-level transportation of ultra-high and large-scale equipment across bridges and culverts. The equipment 9 is fixed on the transport cart by a ladder-shaped transport saddle 7, and both sides of the ladder-shaped transport saddle 7 are provided with jacking steps. 7-1 and the load-bearing support step surface 7-2, the bottom surface of the middle part of the ladder-shaped transport saddle 7 is a horizontal plane, and the jacking step surface 7-1 of the ladder-shaped transport saddle is higher than that of the ladder-shaped transport saddle. The load-bearing support step surface 7-2 is higher, and the load-bearing support step surface 7-1 is higher than the middle botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com