Municipal engineering environmental sanitation garbage can carrying frame

A technology of trash cans and transport racks, which is applied in the field of municipal engineering, can solve problems such as poor use effect, waste of time and manpower, and wear and tear of trash cans, and achieve the effects of improving transport efficiency, reducing physical exertion, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

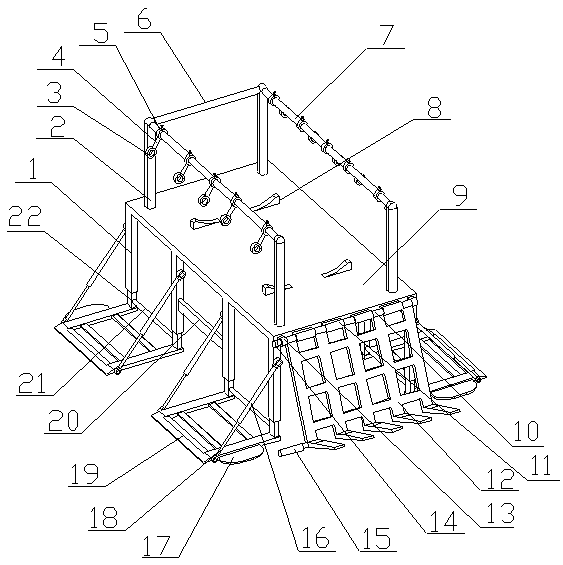

[0023] A municipal engineering environmental sanitation garbage can transport frame of the present invention is realized in this way. When in use, the flip frame (12) is turned up to be perpendicular to the fixed plate (9) in a natural state. The magnet at the bottom of the fixed plate (9) fixes the fixed plate (9) on the electric tricycle, and makes the turning frame (12) correspond to the tail end of the electric tricycle, so that the four support frames (19) hang on the sides of the electric tricycle respectively side, and then press down on the pedal (17), the pedal (17) drives the two connected telescopic rods (22) to slide down along the corresponding hollow rods (1), and the telescopic rod (22) drives the connected compression spring Stretching, and the support frame (19) drives the two connected extension rods (18) to deflect, and the two extension rods (18) respectively drive the connected pull rods (16) to deflect through the compression springs, and respectively move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com