Lifting appliance applied to vehicle machining

A spreader and vehicle technology, applied in the direction of load block, clockwork mechanism, load suspension components, etc., can solve the problems of inconvenient use, lack of transportation effect, poor transportation efficiency, etc., and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

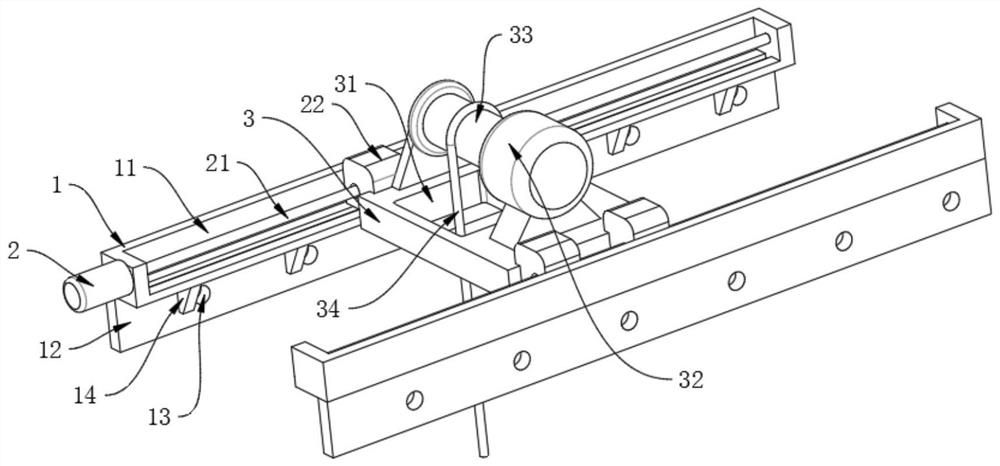

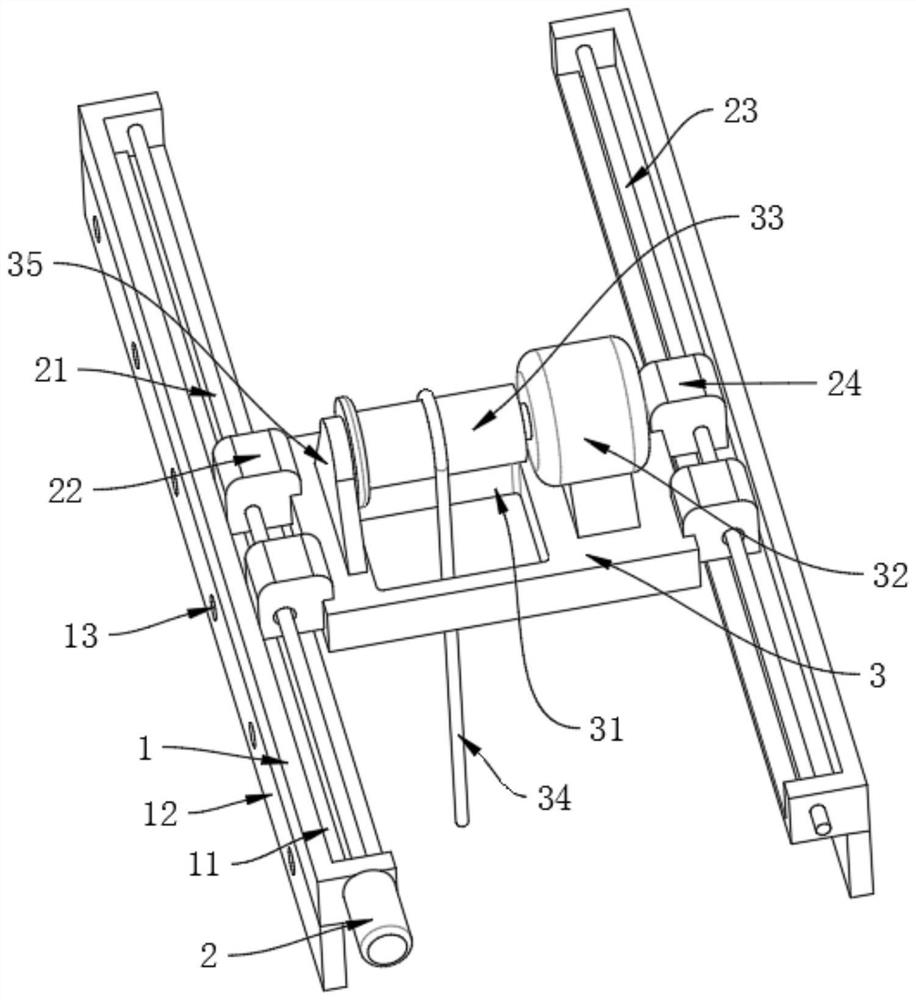

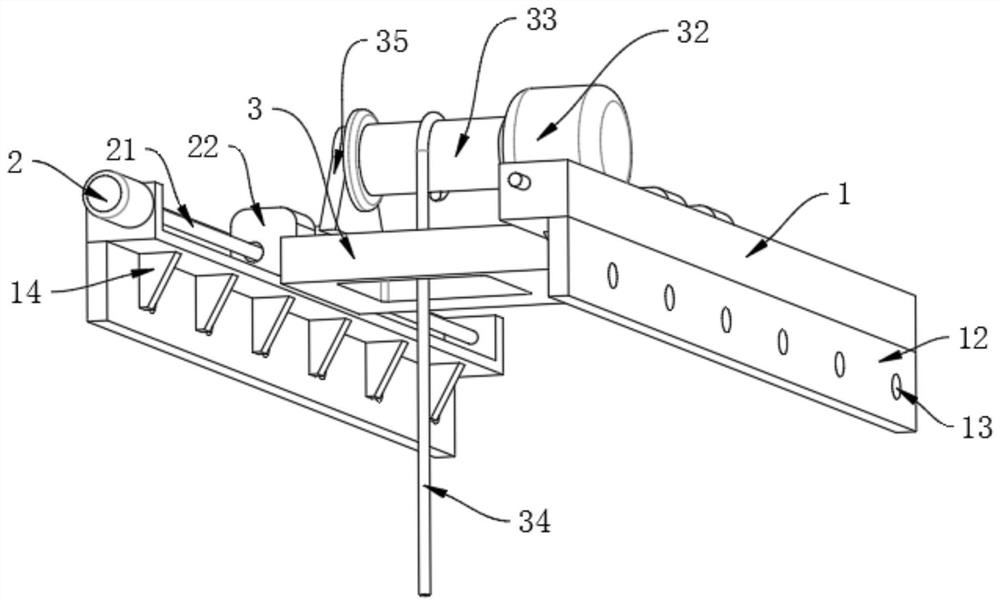

[0021] Example 1, such as Figure 1-3 As shown, the present invention provides a hoisting spreader applied to vehicle processing, comprising two symmetrically arranged carriages, the carriages comprising a sliding seat 1, the upper surface of the sliding seat 1 is provided with a chute 11, and the lower surface of the sliding seat 1 is The surface is fixedly connected with a fixed plate 12, the outer surface of the fixed plate 12 is uniformly provided with a plurality of connecting holes 13, the inner surface of the fixed plate 12 is fixedly connected with a reinforcing rib 14, and the reinforcing rib 14 is fixedly connected with the bottom of the sliding seat 1;

[0022] Wherein the outer surface of the carriage is fixedly connected with the first motor 2, the driving end of the first motor 2 is fixedly connected with the threaded rod 21, the outer surface of the threaded rod 21 is threaded with two first sliding blocks 22, and the inner surface of the other carriage is fixedl...

Embodiment 2

[0024] Example 2, such as Figure 1-3 As shown, the threaded rod 21 is located inside the chute 11, and the end surface of the threaded rod 21 is rotationally connected with the inner surface of the sliding seat 1, the outer surfaces of the two first sliding blocks 22 are slidably connected with the chute 11, and the outer surfaces of the two second sliding blocks 24 are The surface is slidably connected with the chute 11, the outer surfaces of the two first sliding blocks 22 and the two second sliding blocks 24 are fixedly connected with a fixed seat 3, the upper surface of the fixed seat 3 is provided with a through hole 31, and the upper surface of the fixed seat 3 is fixedly connected There is a second motor 32, the driving end of the second motor 32 is fixedly connected with a rotating cylinder 33, the end surface of the rotating cylinder 33 is rotatably connected with a rotating seat 35, the lower surface of the rotating seat 35 is fixedly connected with the upper surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com