Reaction cup push block and reaction cup loading device

A technology of loading device and reaction cup, applied in the direction of analyzing materials, instruments, etc., can solve problems such as stuck pipes and falling into through holes, and achieve the effects of preventing accumulation, preventing pipe stuck, and simplifying the control process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051]In order to better understand the present invention, the cuvette pushing block and cuvette loading device according to the embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

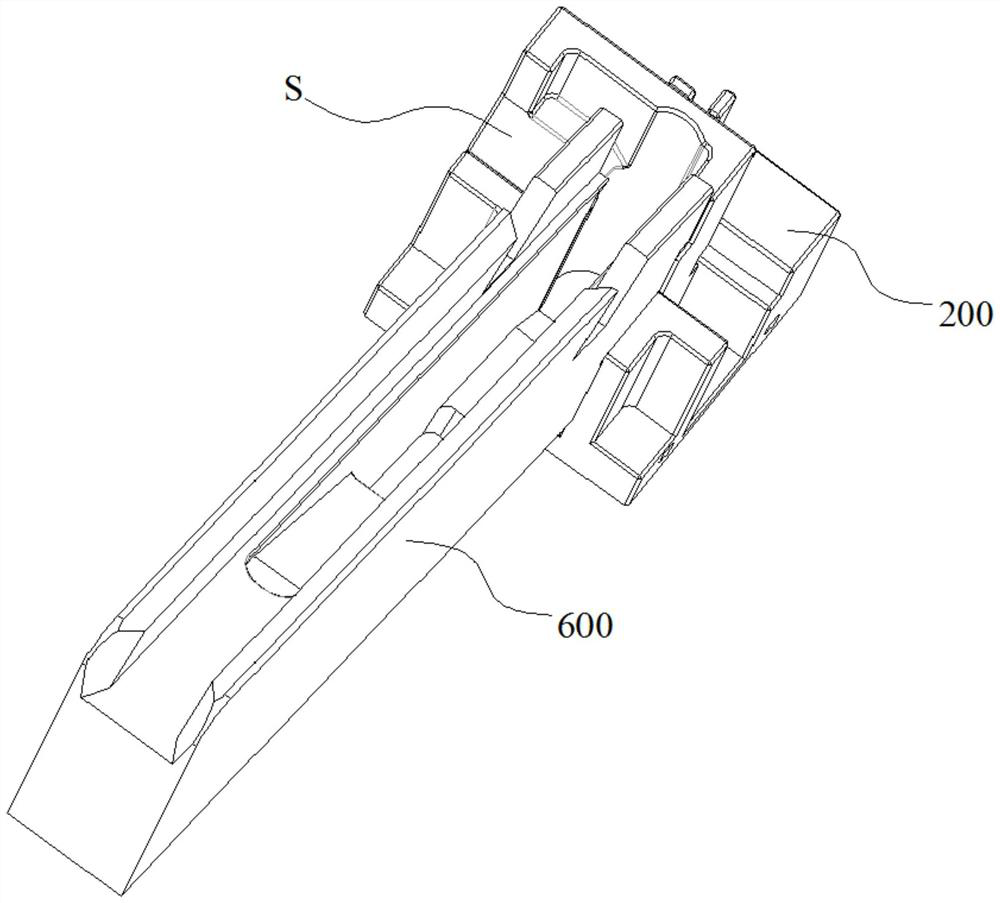

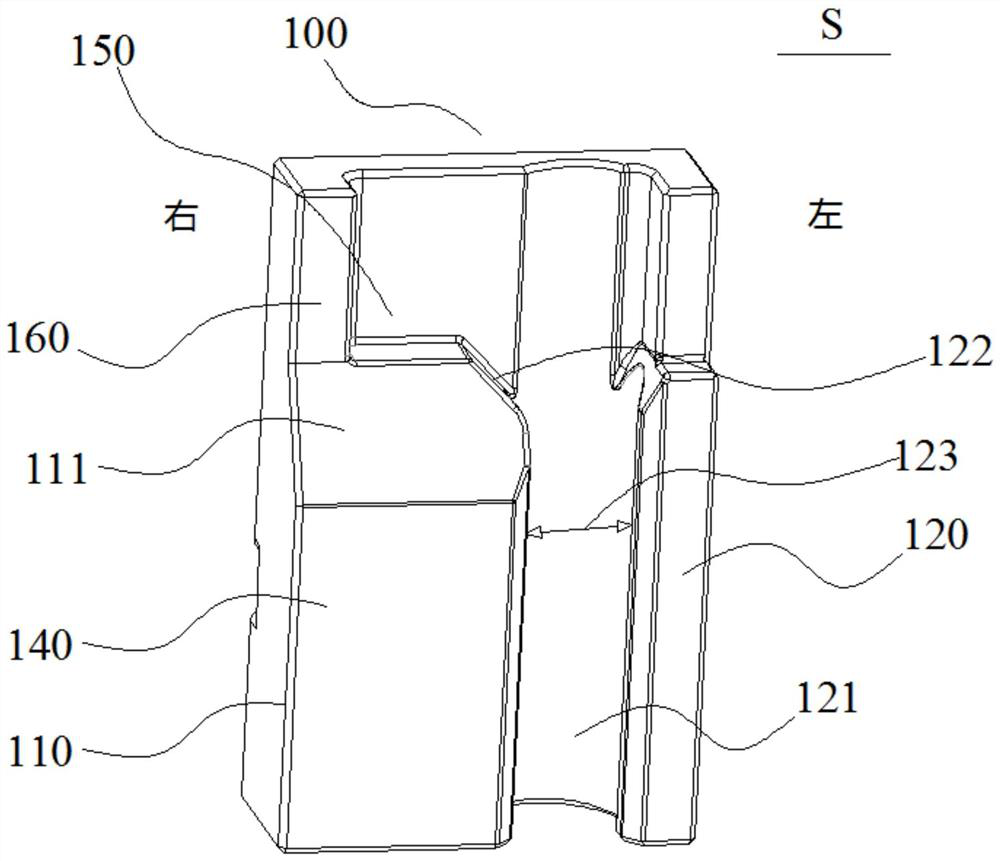

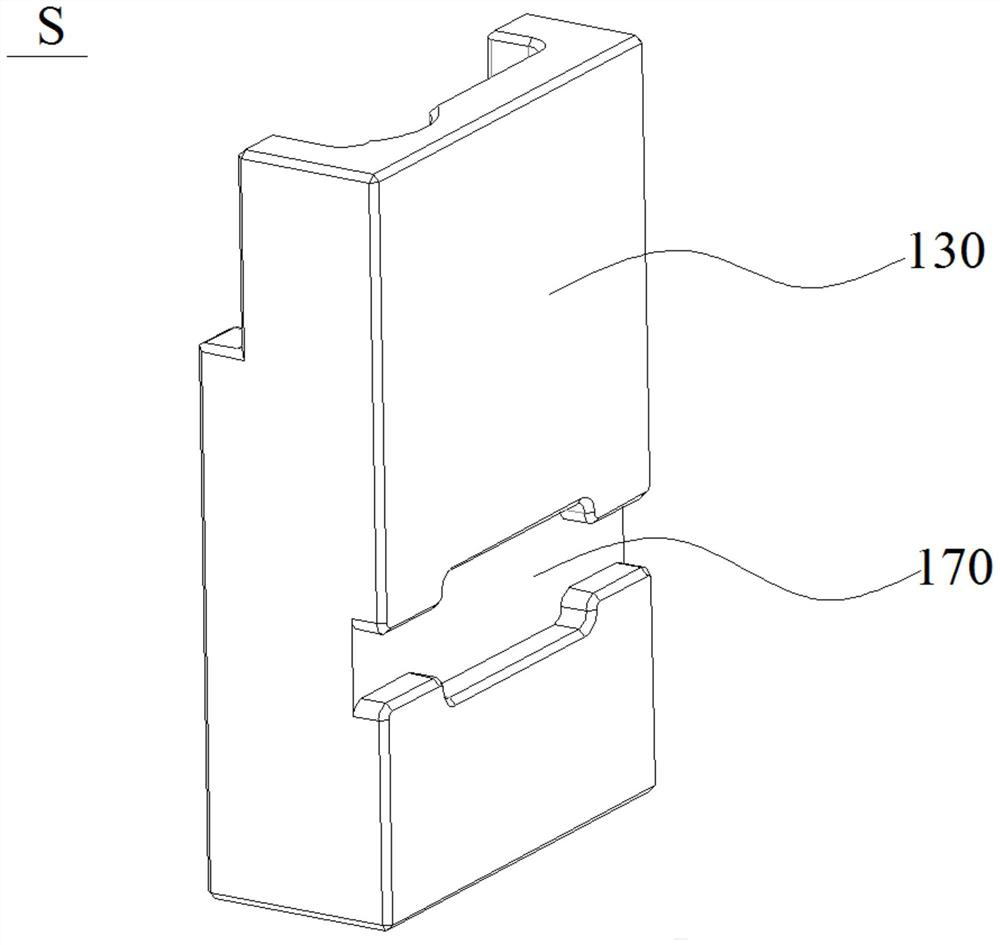

[0052] like Figure 1 to Figure 12 As shown, the cuvette push block S in this embodiment includes a push block body 100. The push block body 100 is provided with a cup body blocking portion 110 and a cup body guide portion 120. The cup body blocking portion 110 is used to block the waiting station. The cuvette N of W, the cuvette guide part 120 is used to guide the single cuvette N at the waiting station W to the next station,

[0053] The push block body 100 can move in the push block movement channel 201 on the base 200. By moving the push block body 100, the cup body blocking portion 110 or the cup body guide portion 120 on the push block body 100 can be connected to the waiting station W. When docked, the cuvette at the waiting s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com