Steel bar straightening machine

A technology for straightening machines and steel bars, which is applied in the field of wheel hub bearings, can solve the problems of inability to effectively straighten universally twisted steel bars, inconvenient straightening of steel bars for automatic feeding of steel bars, and unsatisfactory straightening effects, etc. Small friction, improve the effect of elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

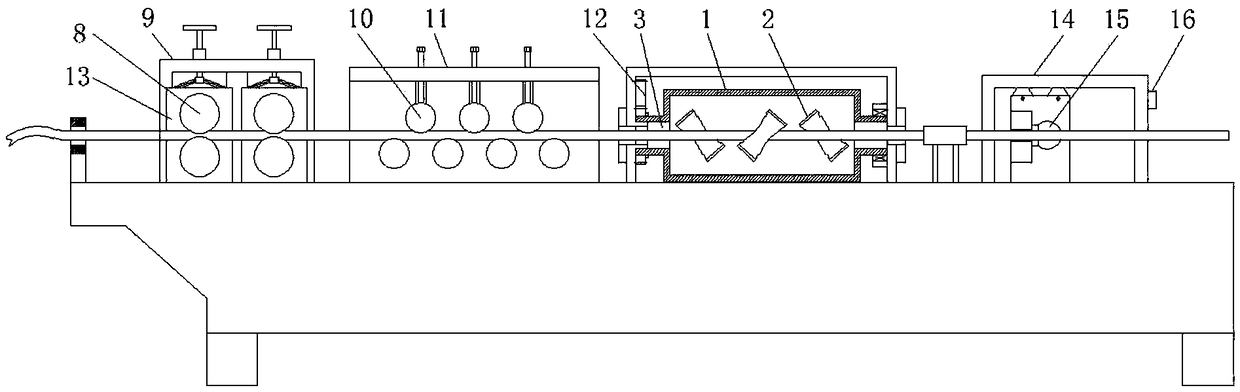

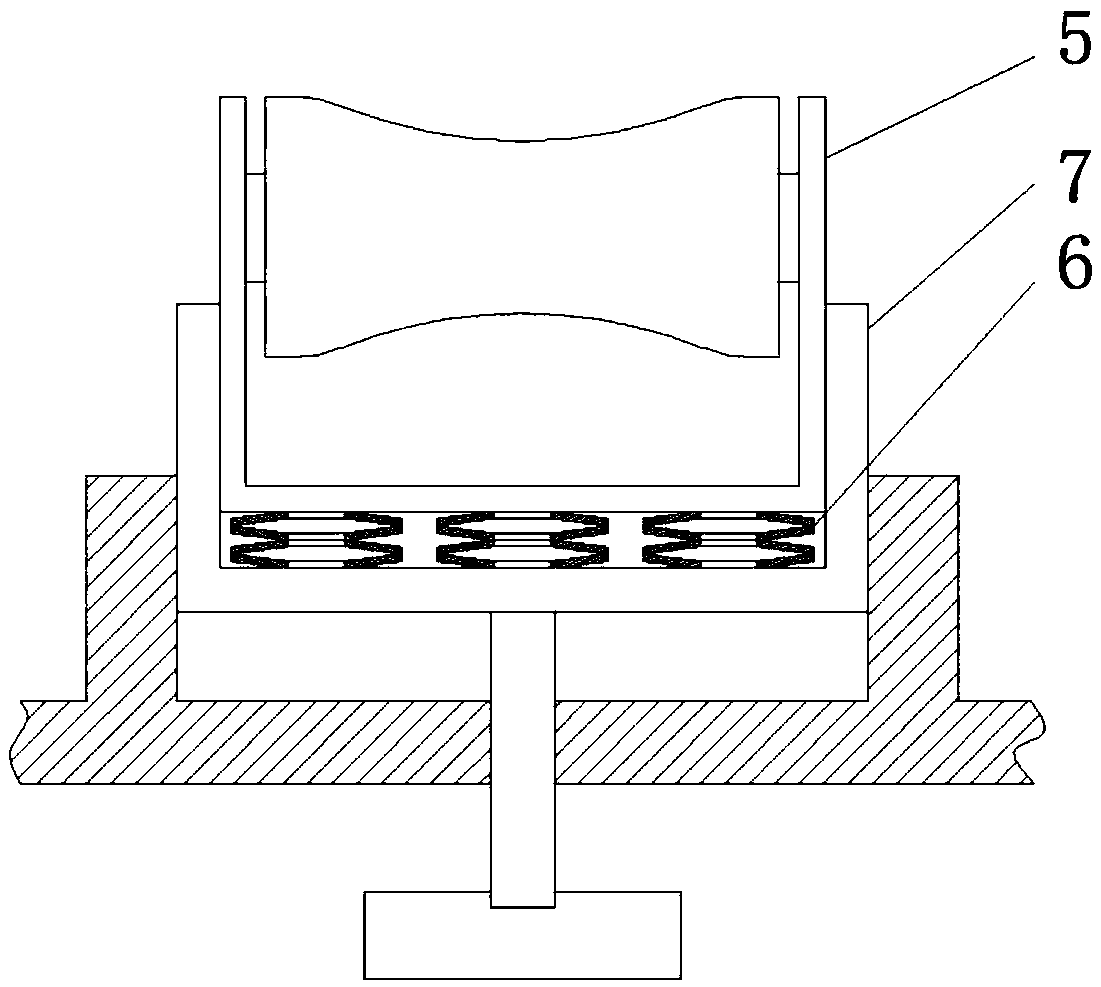

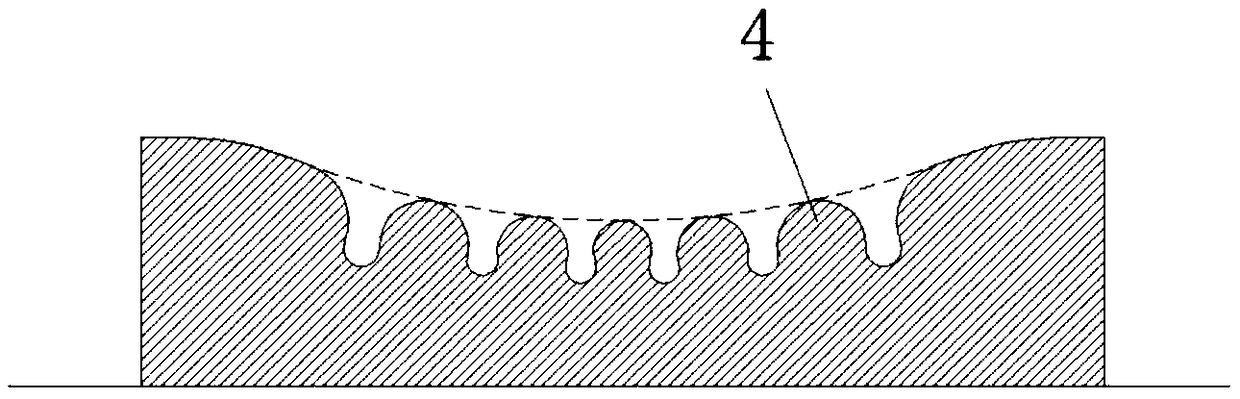

[0022] figure 1 It is a structural schematic diagram of the present invention; figure 2 It is a schematic diagram of the inclined roller structure; image 3 is a schematic diagram of the bump structure;

[0023] As shown in the figure: it includes a straightening cylinder 1 and several inclined rollers 2 arranged in the straightening cylinder for eliminating the internal stress of the steel bars. The two ends of the straightening cylinder 1 are coaxially provided with openings 3 for the entry and exit of steel bars. The oblique rollers 2 are alternately arranged on both sides of the radial direction of the steel bar and are used to cooperate with the outer surface of the steel bar to roll. The axes of the oblique rollers 2 and the axis of the straightening cylinder 1 are arranged at an angle. The hemispherical contact protrusion 4 protrudes outward along its radial direction. The radius of the contact protrusion 4 gradually increases from the axial middle of the inclined ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com