Rebar wire straightening and tailoring mechanism

A technology of wire rod and steel bar, applied in the field of steel wire rod straightening and cutting mechanism, can solve the problems of many wearing parts of equipment, inability to work continuously, poor straightening quality, etc., and achieve high work efficiency, improved work efficiency, and straightening effect. ideal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

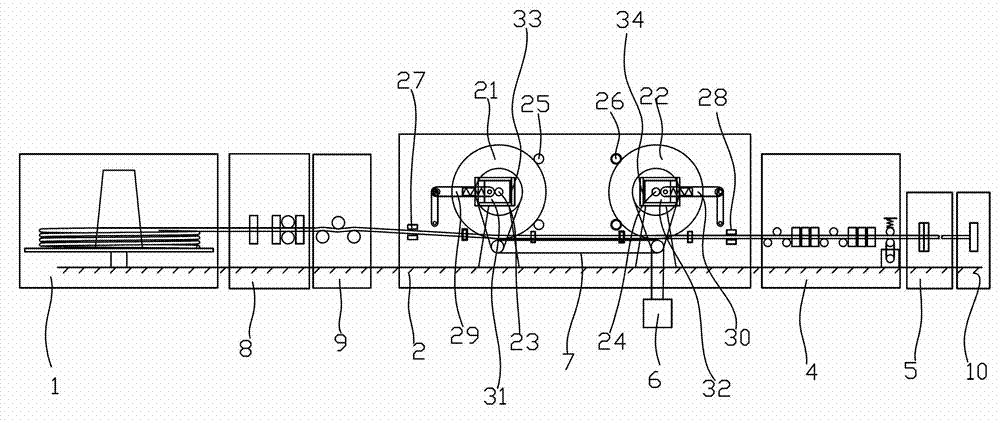

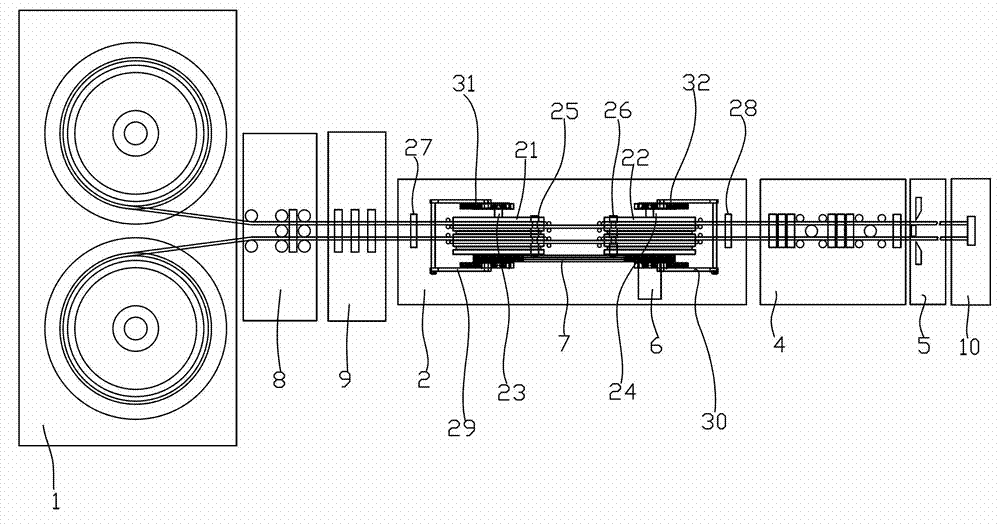

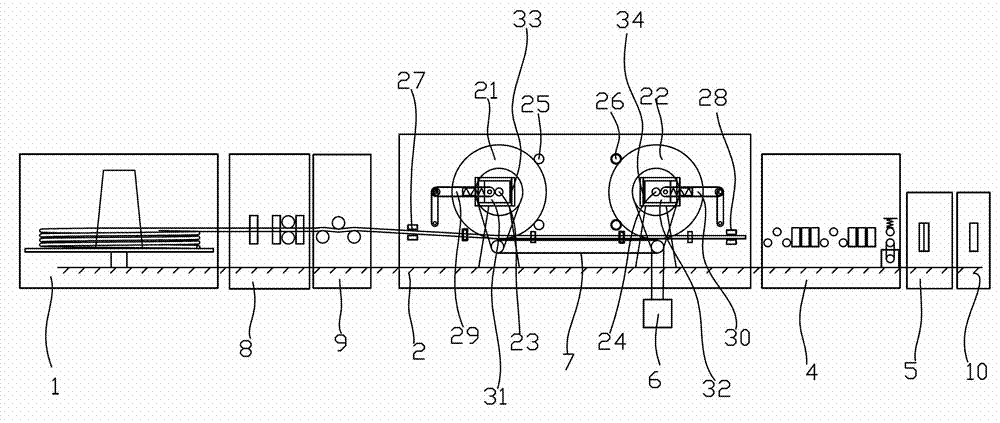

[0028] refer to Figure 1-8 , a steel bar wire straightening and cutting mechanism, comprising a feeding device 1, a pulling wheel set 2, a straightening device 4 and a cutting device 5 connected in sequence, the pulling wheel set 2 includes at least two pulling wheels, and the wires are wound in turn Placed on the driving wheel, it also includes a power device 6 that provides power for the driving wheel set 2. In the driving wheel set 2, the linear speed of the driving wheel located at the rear along the wire conveying direction is greater than the linear speed of the driving wheel located at the front.

[0029] Utilizing the technical feature that the linear velocity of the pulley that the wire passes through first is smaller than that of the pulley that passes through later, the pulley set 2 can continuously stretch and straighten the steel bars and other wires that pass through the circle, and the efficiency is high. At the same time, the mechanism has little damage to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com