Two-way straightening machine driven by single power source

A power source, straightening machine technology, applied in mechanical equipment, transmission, belt/chain/gear, etc., can solve the problems of pressure exerted on steel and insufficient straightening accuracy, and achieve improved straightening accuracy and straightening effect. , the effect of improving the coordination of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings.

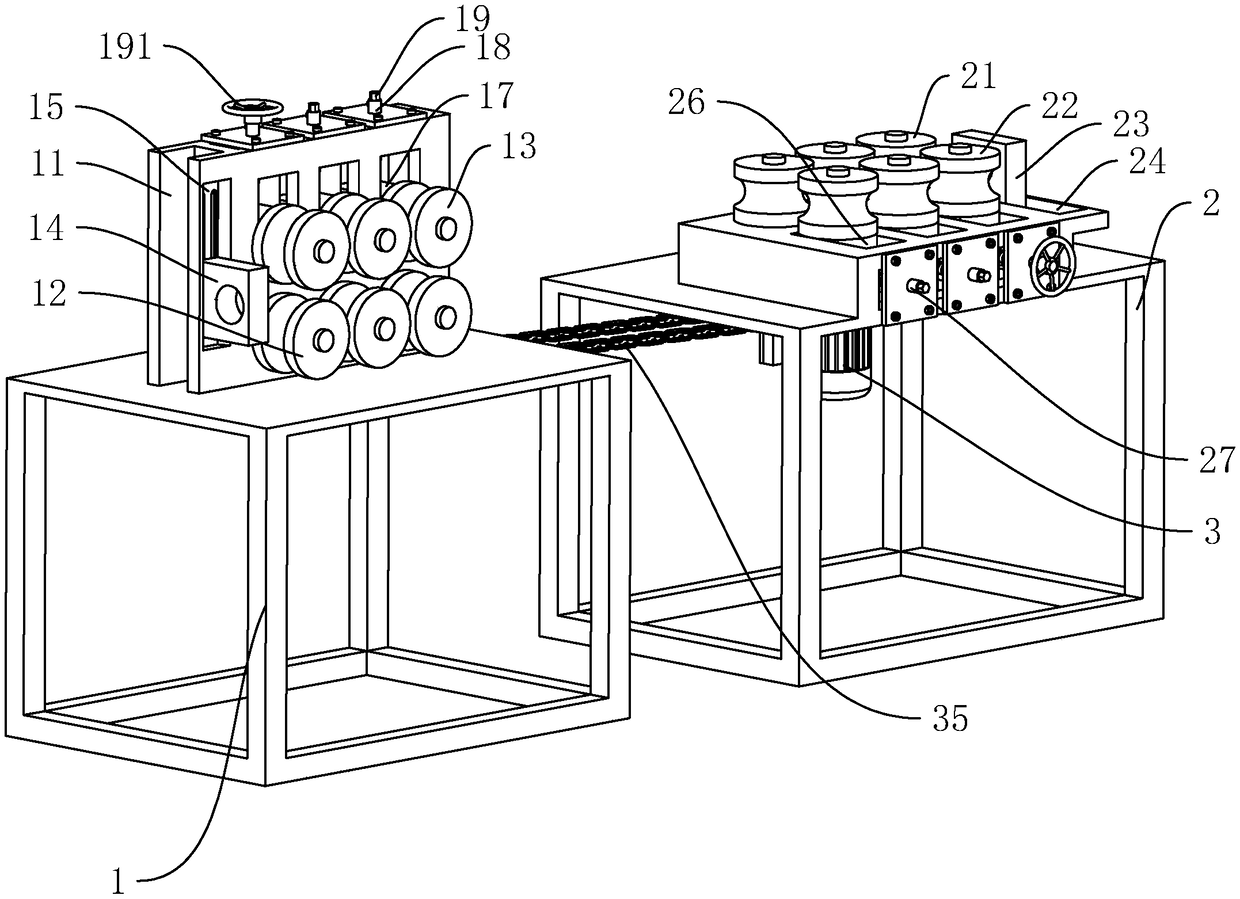

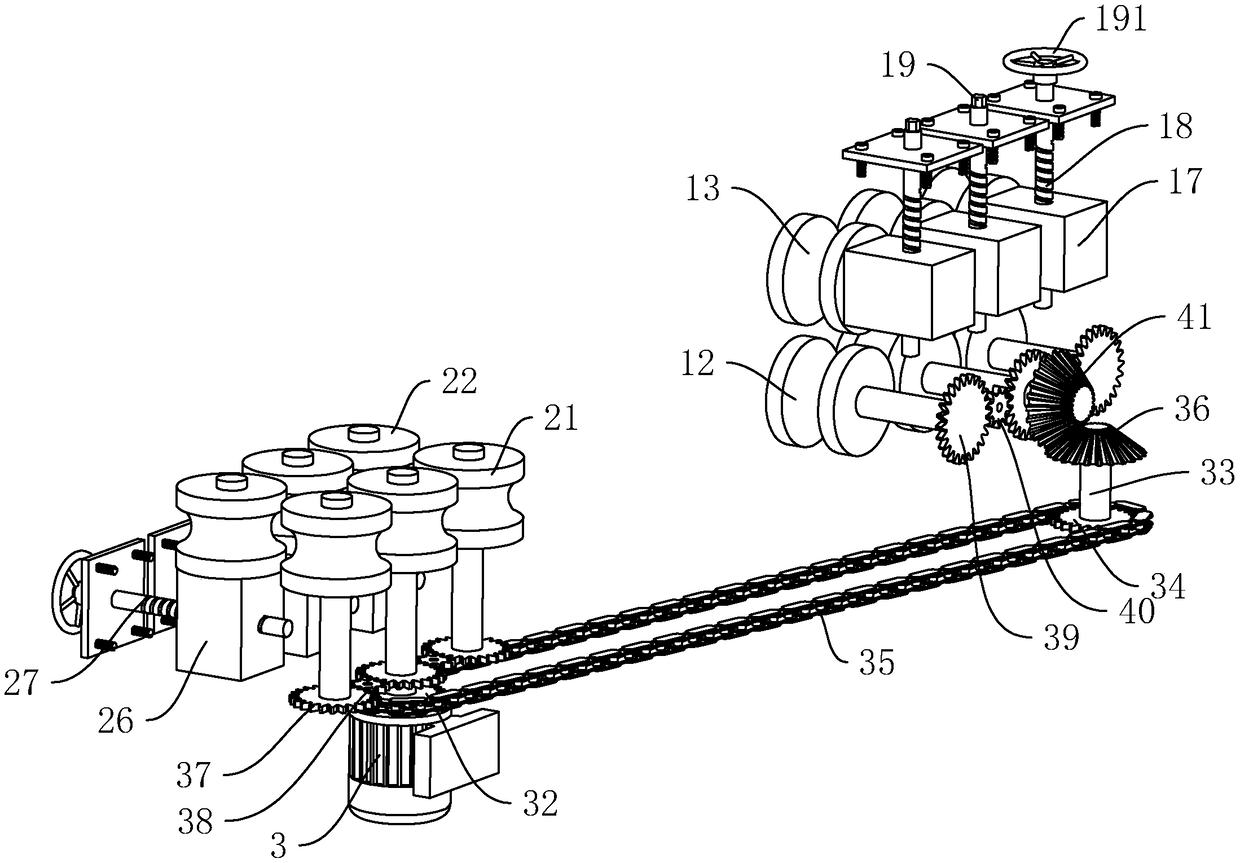

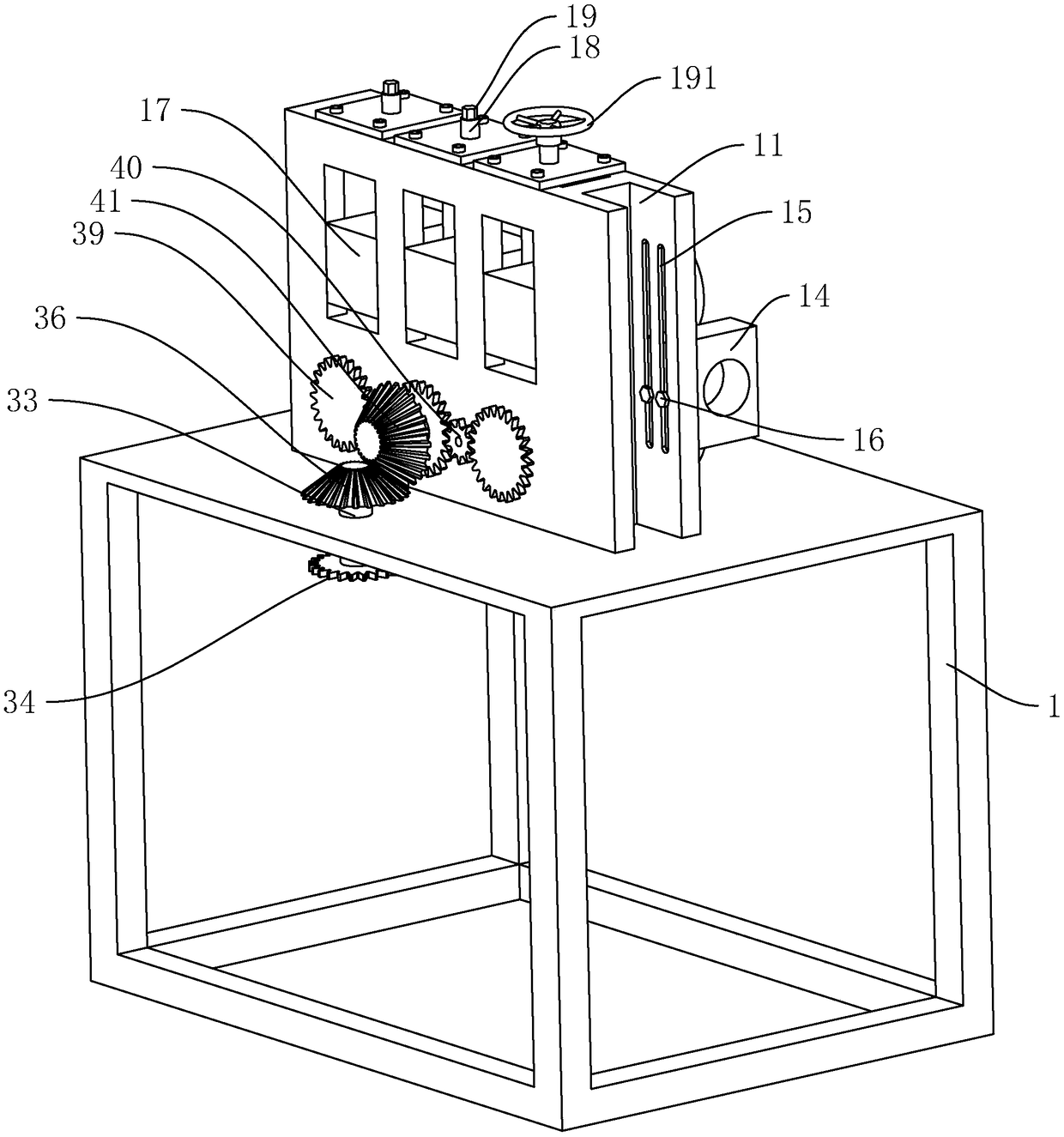

[0030] Two-way straightening machine driven by a single power source, such as figure 1 , figure 2As shown, it includes a vertical straightening mechanism, a horizontal straightening mechanism, and a power mechanism that simultaneously drives the vertical straightening mechanism and the horizontal straightening mechanism; the vertical straightening mechanism includes the first workbench 1, which is vertical Weld and fix the vertical mounting plate 11 on the upper surface of the first workbench 1, and a plurality of vertical power wheels 12 that are rotatably connected to the vertical mounting plate 11. The multiple vertical power wheels 12 are arranged in a straight line, and the vertical mounting plate 11 corresponds to each vertical power wheel 12 which slides longitudinally and is rotatably connected with a vertical pressure wheel 13; the horizontal strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com