Outer wall welding unit for gaseous pollutant purification equipment

A technology for purifying equipment and pollutants, applied in the field of plate welding, can solve the problems of wasting labor, lack of guarantee of welding sealing, low production efficiency, etc., and achieve the effects of reducing labor costs, convenient starting point, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

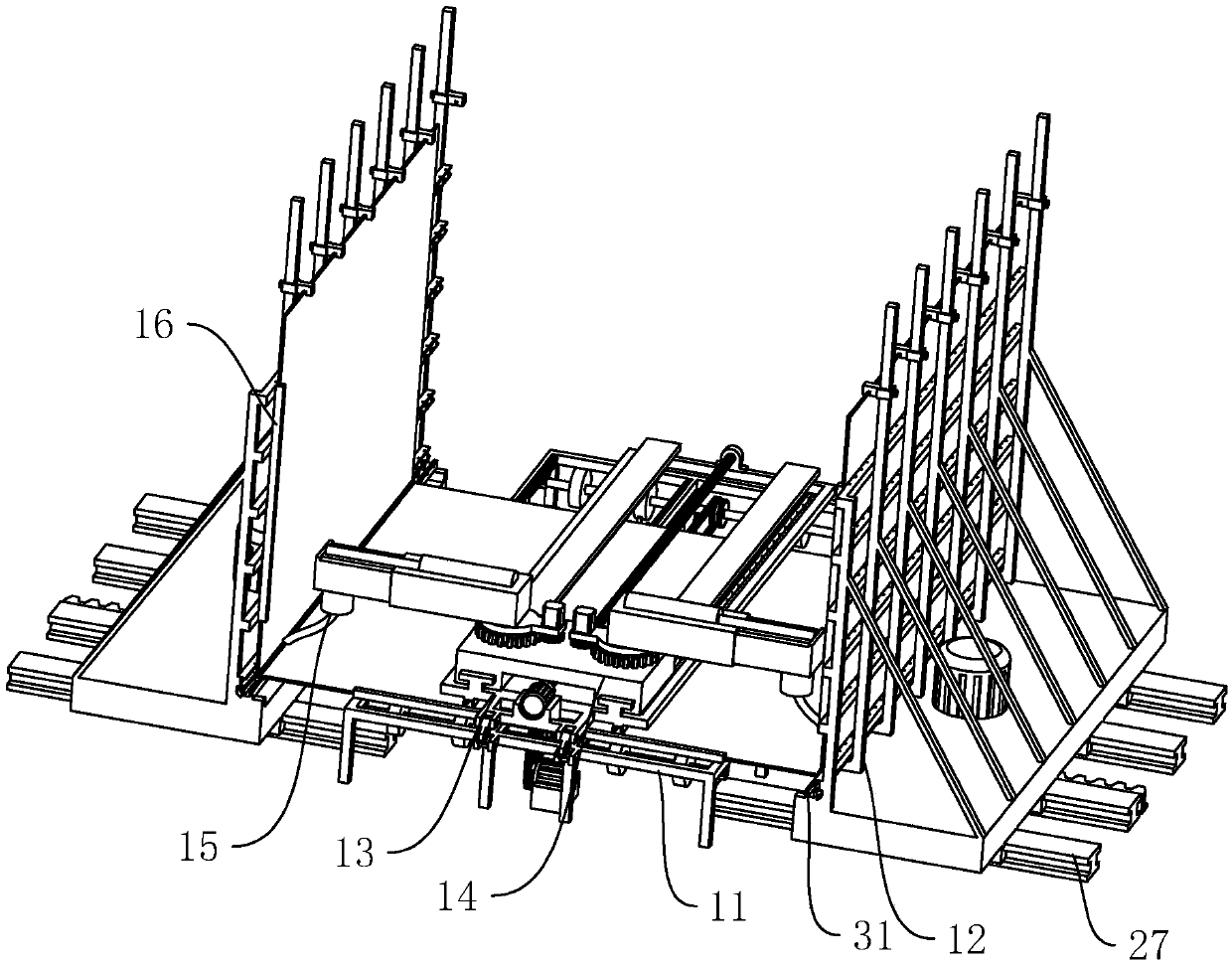

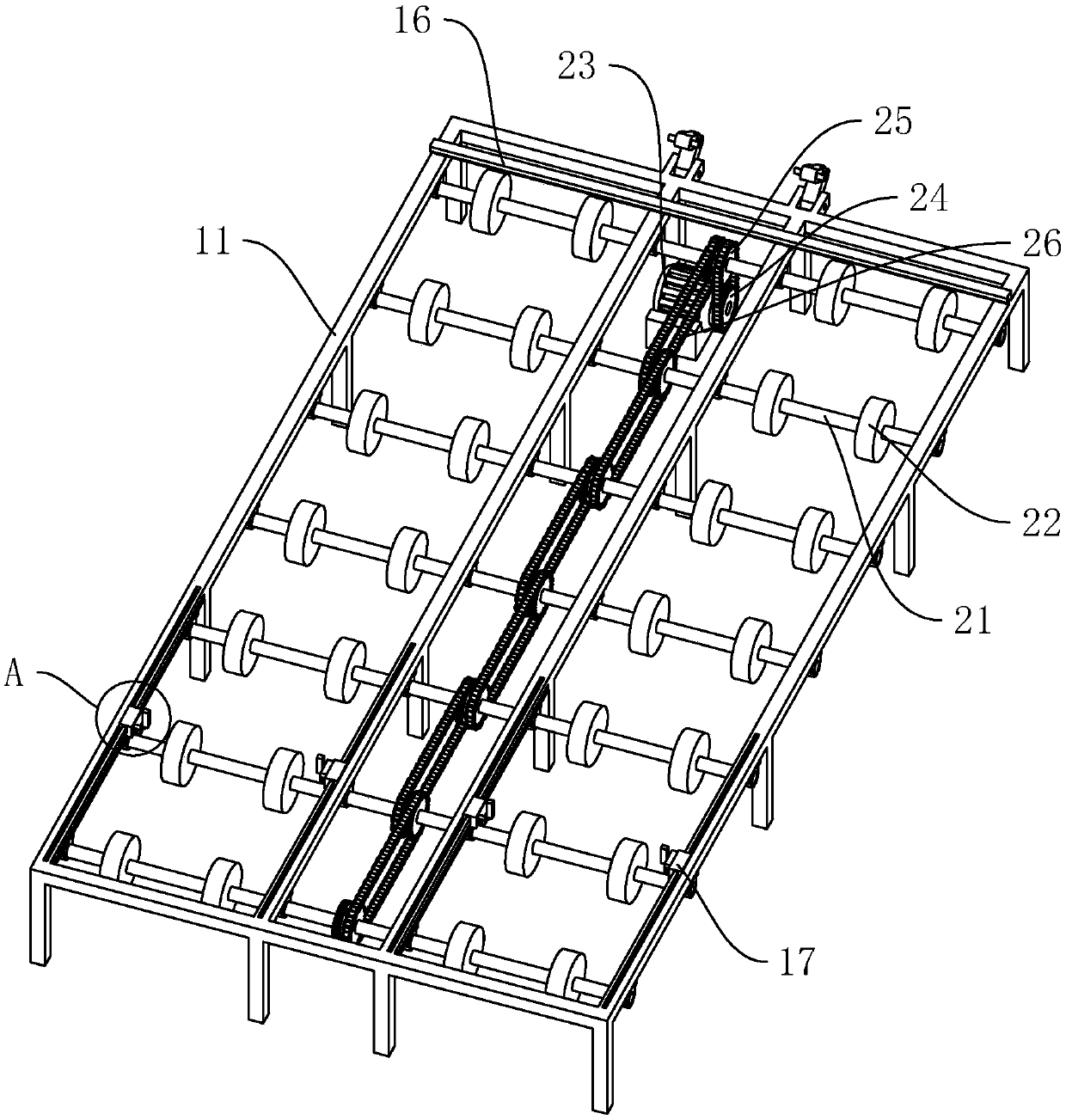

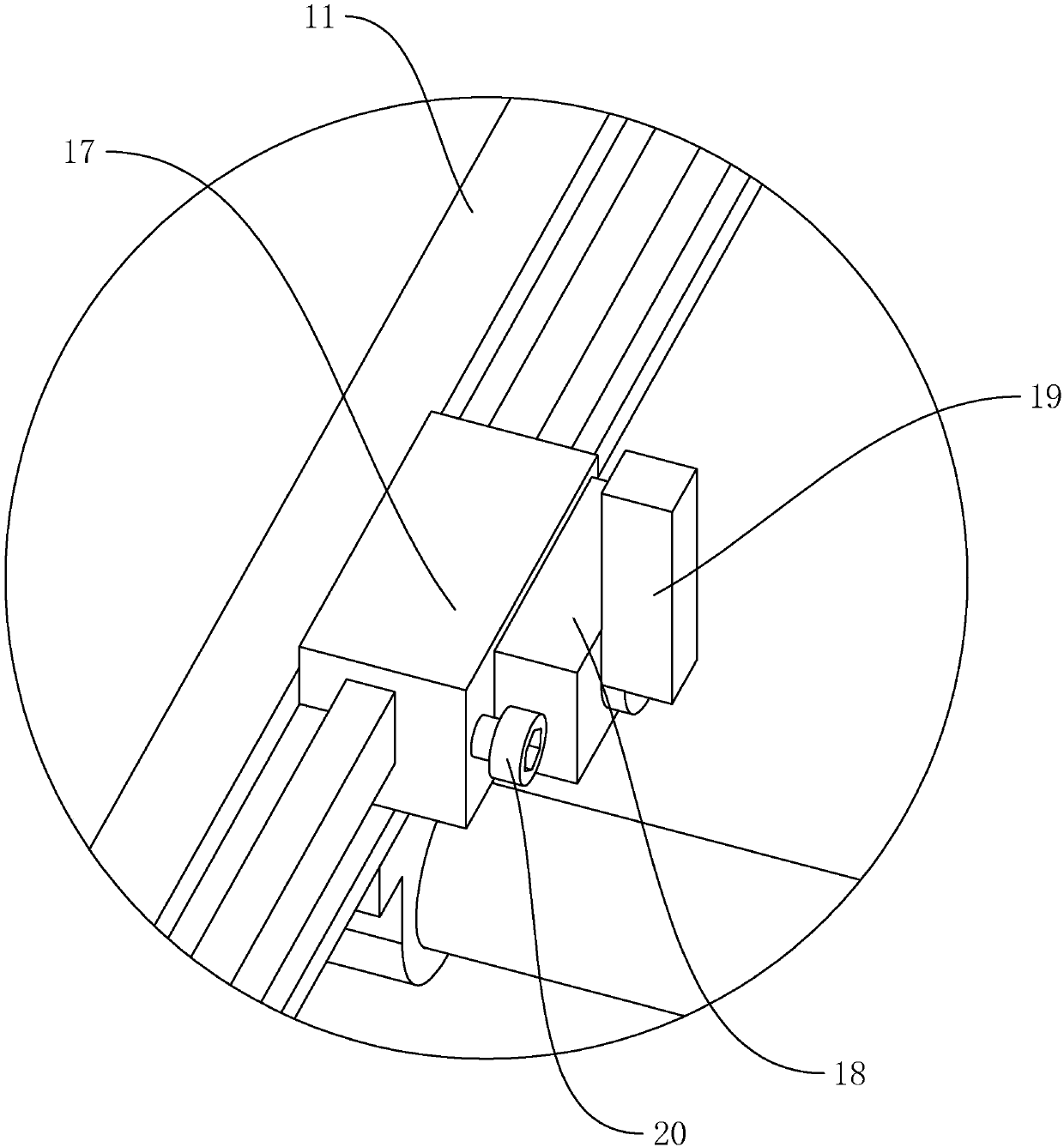

[0035] External wall welding units for gaseous pollutant purification equipment, such as figure 1 As shown, it includes a horizontal frame 11, a vertical frame 12 relatively arranged on both sides of the horizontal frame 11, a pressure rail 13 hinged at one end to the horizontal frame 11, a mobile seat 14 sliding along the length direction of the pressure rail 13, and two mounted on The welding torch 15 of the mobile seat 14.

[0036]When the present invention is working normally, a stainless steel plate is inserted between the horizontal frame 11 and the pressure rail 13, the other two stainless steel plates are respectively fixed on the two vertical frames 12, the welding torch 15 is started and the moving seat 14 is controlled to press The rail 13 slides at a constant speed in the length direction, so that the two joints of the three stainless steel plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com