Steel wire straightener

A straightener and steel wire technology, applied in the field of wire straighteners, can solve the problems of unfavorable operation, reduced service life, inconvenient process adjustment and adjustment, etc., and achieves the effects of easy component replacement, simple overall structure and good straightening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

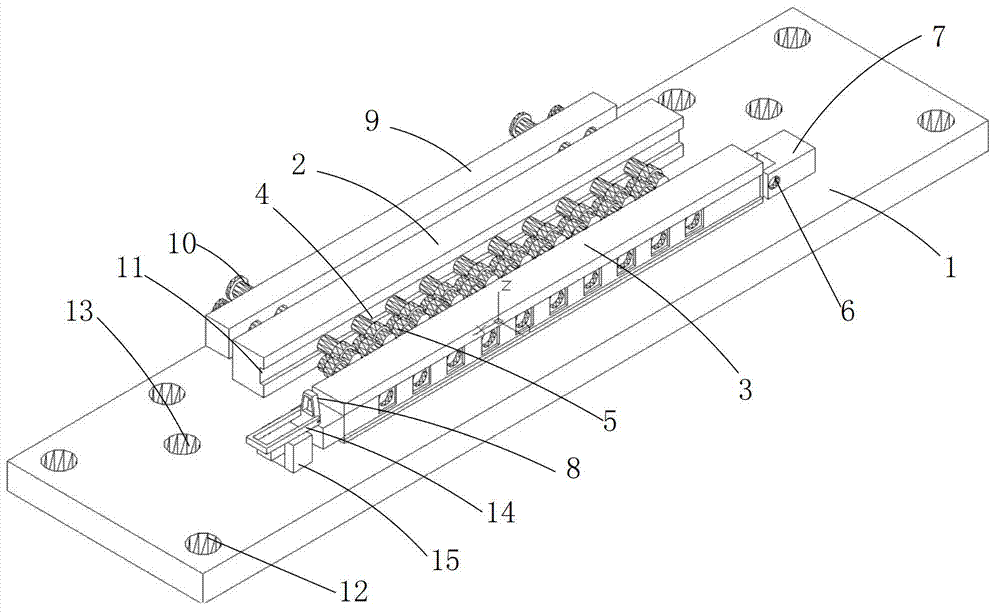

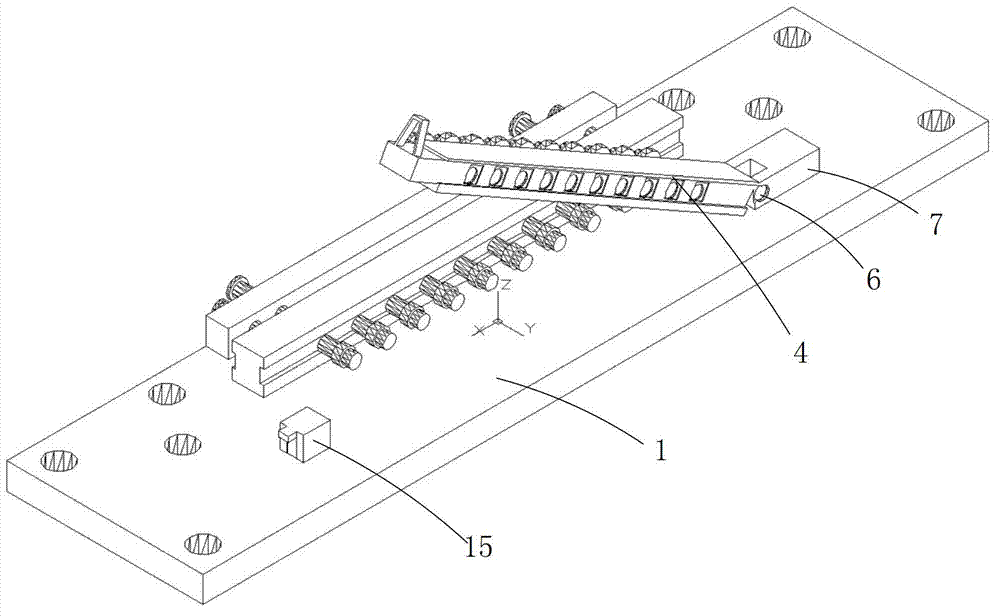

[0021] Such as figure 1 with figure 2 As shown, the steel wire straightener of the present embodiment includes a base 1, and the base 1 is provided with an upper pressing frame 2 and a lower bracket 3 which are mutually horizontal, and the upper pressing frame 2 and the lower bracket 3 are oppositely arranged Straightening wheels 4 and straightening blocks 5 are arranged. In this embodiment, the straightening wheel shaft is made of SKH-9 imported material, which is quenched to HRC55-60°, and its wear resistance is improved through fine grinding; the straightening wheel is made of hard alloy material to improve its hardness and wear resistance The straightening block is made of H13 hot work die steel and quenched to HRC48-52°, which improves the toughness and cold and heat fatigue resistance of the straightening block.

[0022] In order to facilitate passing the steel cord on the wire passing wheel through the gap between the straightening wheel 4 and the straightening block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com