High-accuracy straightening machine for tantalum-niobium alloy pipe

A tantalum-niobium alloy, high-precision technology, applied in high-precision straightening machines for alloy pipes, high-precision straightening machines for rare metal alloy pipes, and pipe straightening machines. It can solve difficult problems and expand the straightening range. , Improve straightening ability, improve straightening accuracy and surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the straightener of the present invention is described in further detail;

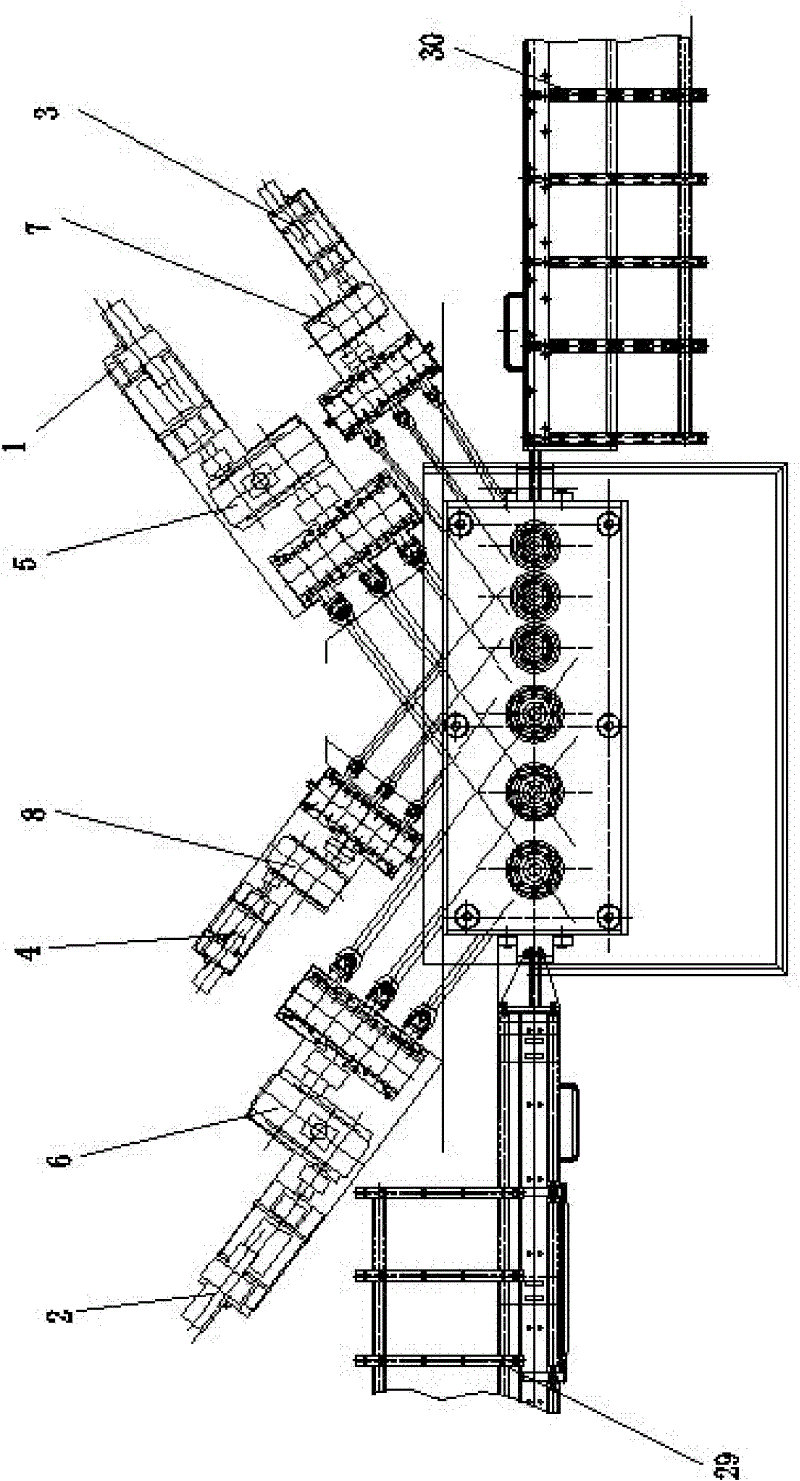

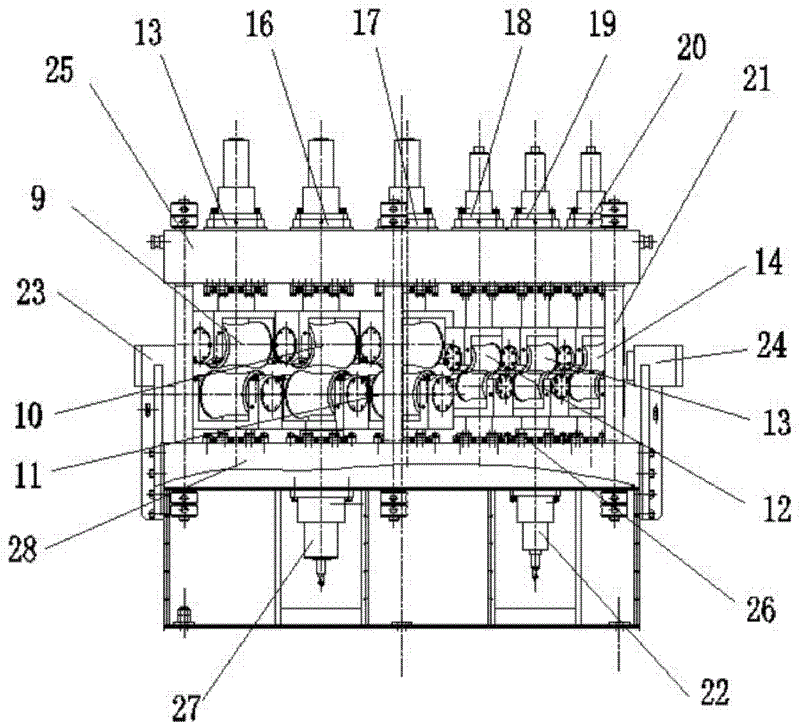

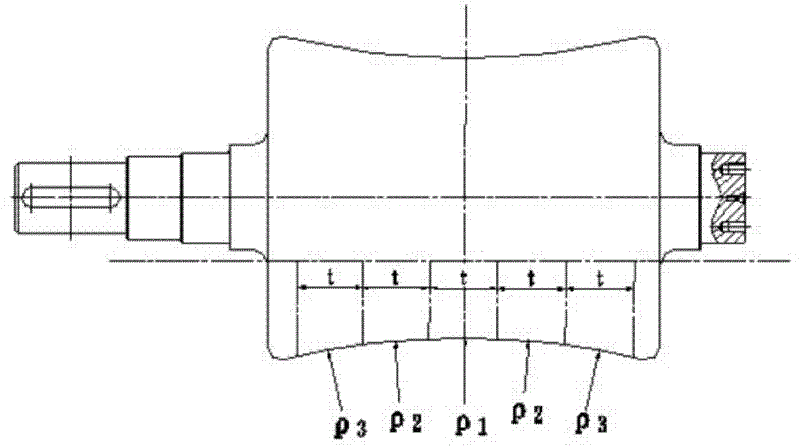

[0025] The straightening machine of the present invention is mainly composed of a distribution table, a feeding rack 29, a feeding roller table, a straightening main machine, a feeding roller table, a feeding rack 30, a collecting device, a C-shaped frame, a hydraulic station, a hydraulic servo system, an electric The composition of the control system;

[0026] The material distributing platform is located at the front end of the straightening machine, the material distributing platform is connected with the feeding roller table, the feeding roller table is connected with the straightening main machine through the guide device, the straightening main machine is connected with the unloading roller table through the guide device, and the unloading roller table is connected with the straightening machine through the guide device. There i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com