Centered guiding device of bars for straightening machine

A straightening machine bar and guide device technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the vibration of the guide plate door and the large increase in the activity range, the guide plate door cannot be effectively locked, and cannot meet the production requirements, etc. problems, to achieve the effect of reducing vibration and activity intervals, reducing oil leakage failures, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

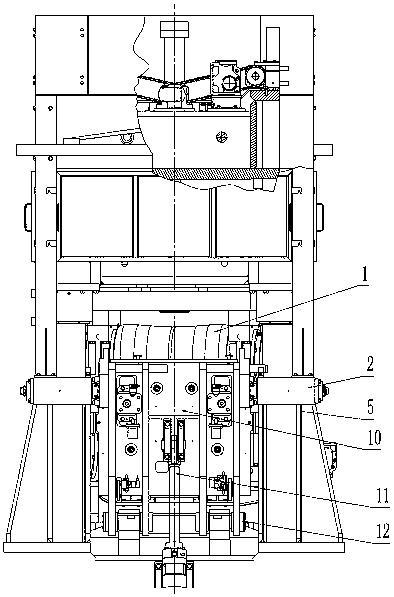

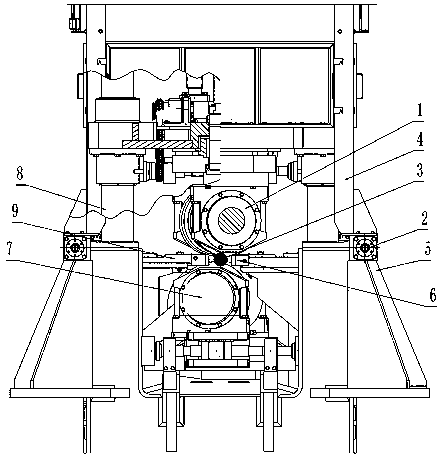

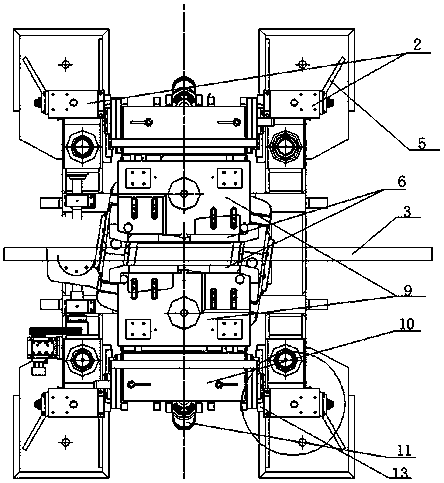

[0024] see Figure 1 to Figure 5 , the main body of the straightener (excluding the main motor and drive shaft) includes: the overall frame of the straightener (including the base of the straightener, the prestressed frame 4 of the straightener and the prestressed column 8 of the straightener), the upper straightening roller 1. The lower straightening roller 7 and the bar centering guide device, wherein the bar centering guide device mainly includes two bar limit units, and each bar limit unit includes a locking cylinder 2 and a guide bar 6 , guide guard plate 9, guide plate door 10, hydraulic support rod 11, rotating shaft 12, guide sleeve 18 and positioning block 19. The guide strip 6 is installed and fixed on the innermost side of the guide plate 9, and can be replaced. The guide strip 6 will be in contact with the bar to ensure that the bar is centered.

[0025] The two-roller straightening machine has two upper and lower straightening rollers. The upper straightening rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com