Bar overturning mechanism and conveying trolley for bar straightening machine

A material straightening machine and turning mechanism technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of bar material turning and slipping, affecting the bar material straightening accuracy, being easily affected by its own swing and inertia, etc. Achieve the effects of avoiding bar swing, improving straightening accuracy, and avoiding inaccurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

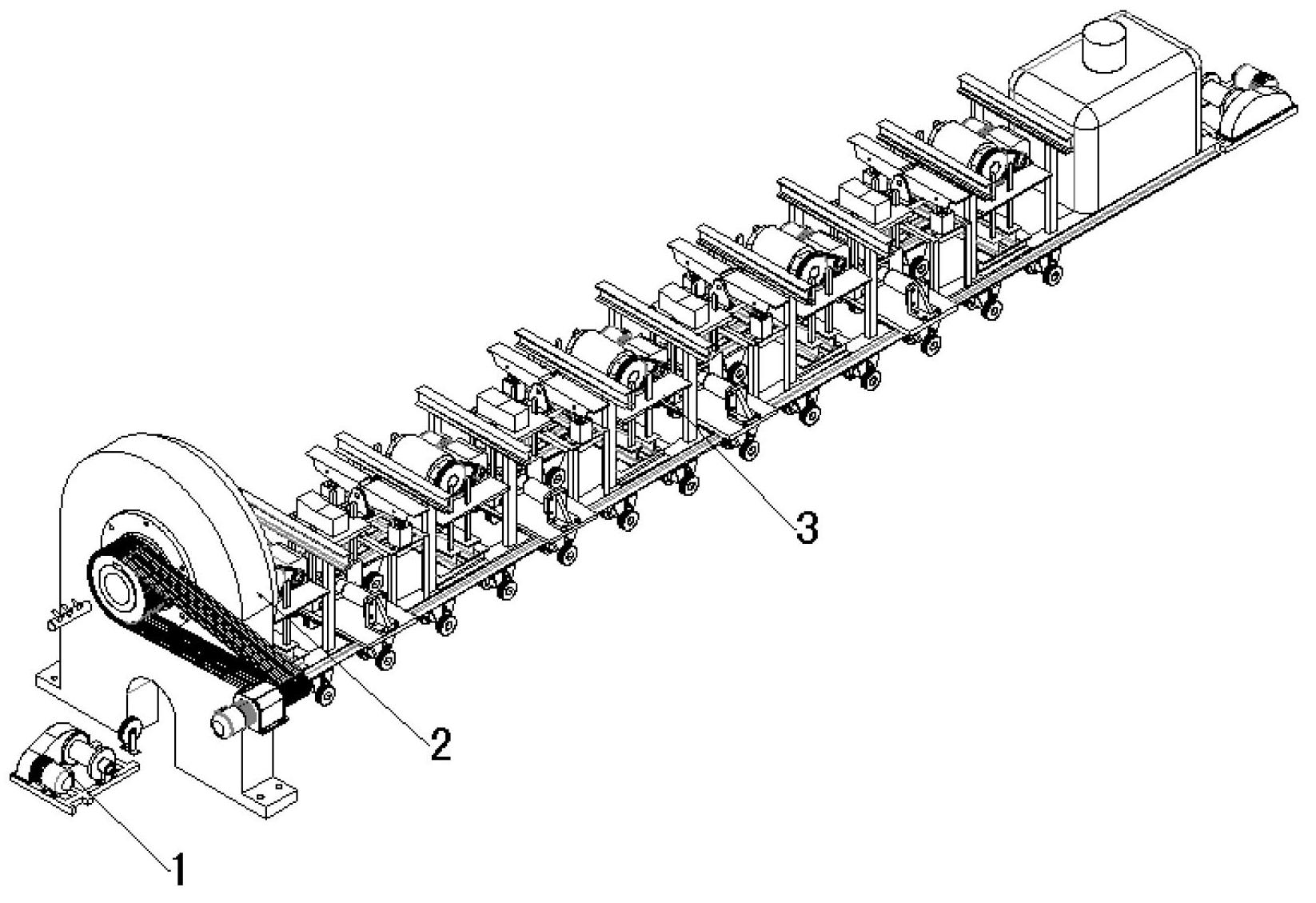

[0029] Such as figure 1 As shown, the turning mechanism and feeding trolley for the bar straightening machine are composed of traction mechanism 1, bar turning mechanism 2, and feeding trolley 3. The traction mechanism 1 is connected with the feeding trolley 3 through a steel rope, and when the feeding trolley 3 is being pulled, the steel rope is always in a taut state.

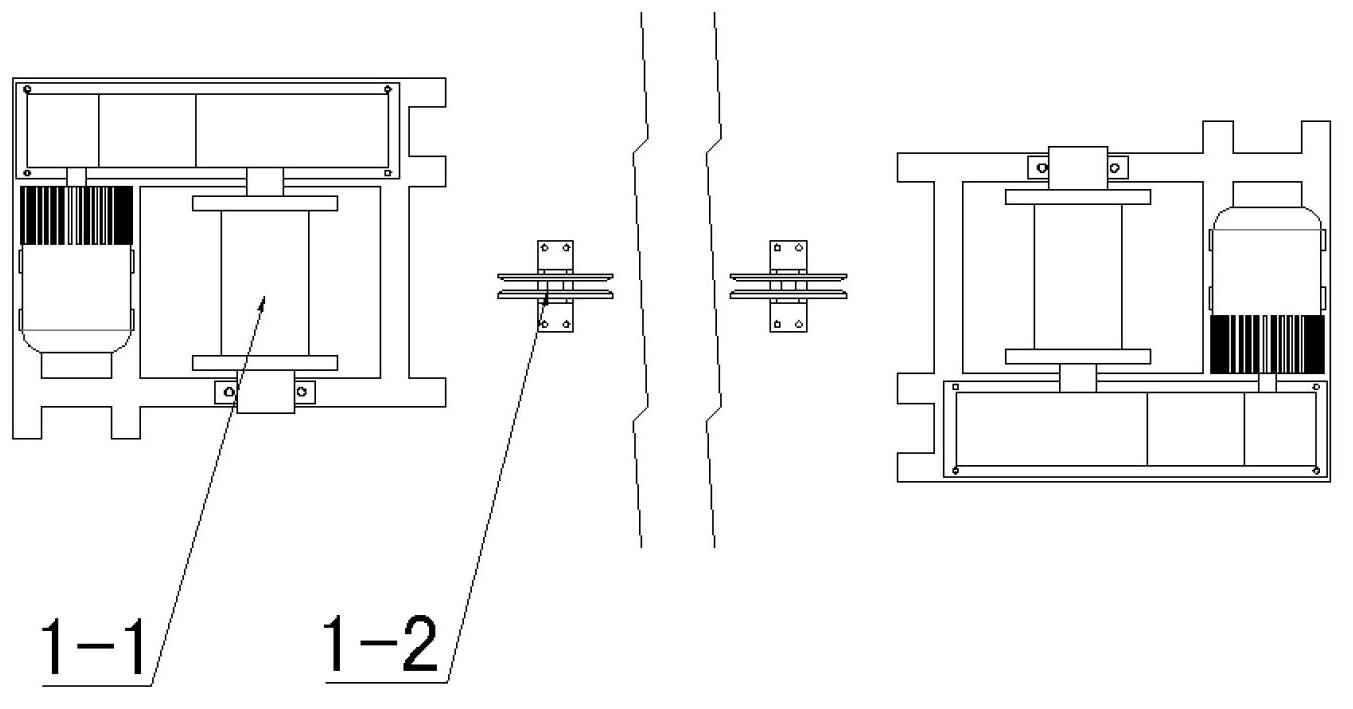

[0030] Such as figure 2 As shown, the traction mechanism 1 is composed of a winch assembly 1-1 and a steel rope guide wheel set 1-2.

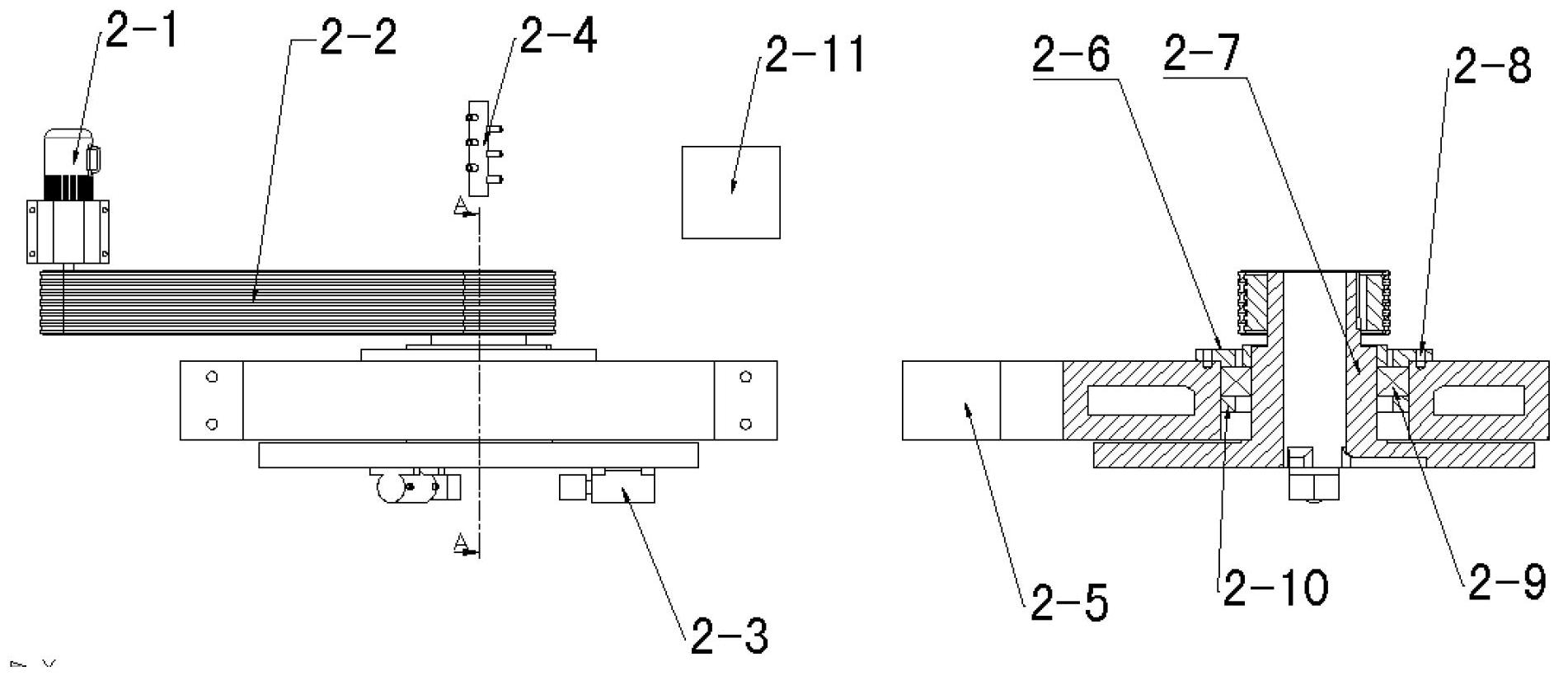

[0031] Such as image 3 As shown, the bar turning mechanism 2 consists of a motor reducer 2-1, a sprocket chain 2-2, a hydraulic gripper 2-3, a hydraulic rotary joint 2-4, a turning base 2-5, and a bearing pretensioner 2- 6. Composed of rotating shaft 2-7, bearing pre-tightening nut 2-8, roller bearing 2-9, sleeve 2-10, and hydraulic pump station 2-11. The hydraulic gripper 2-3 is fixed on one end surface of the rotary shaft 2-7, and the inlet and outlet oil pipes of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com