Rectifying device for large-sized unstable aluminum alloy sections

A technology of aluminum alloy profiles and large specifications, which is applied in the field of straightening devices for large-scale and easily unstable aluminum alloy profiles, and can solve problems such as surface strain of profiles, low straightness of profiles after straightening, and scrapping of profiles due to instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing.

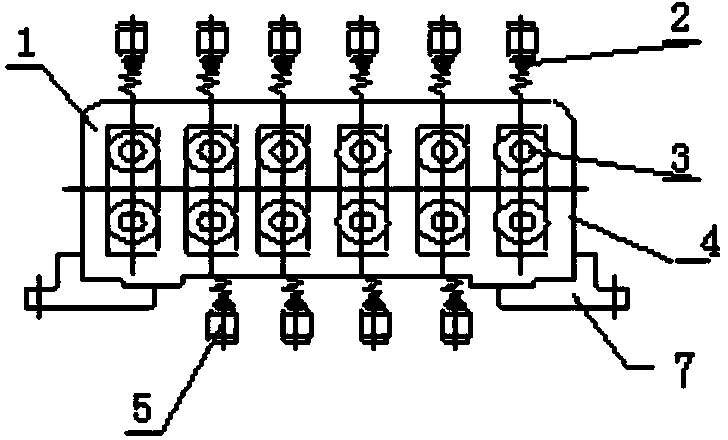

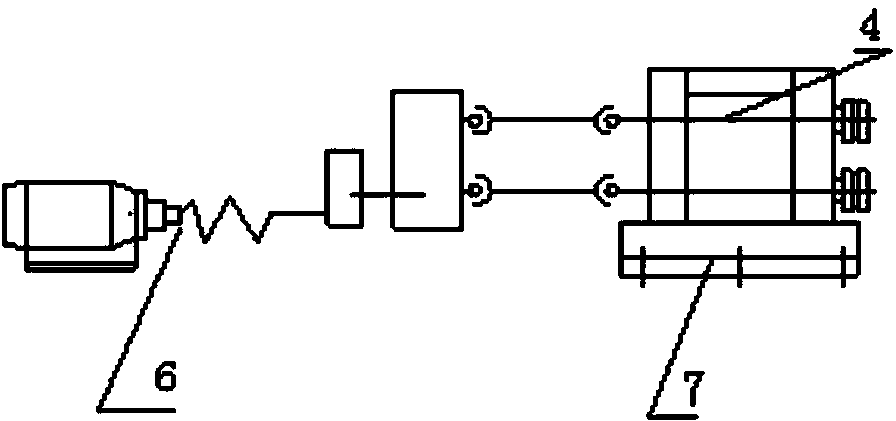

[0010] Such as figure 1 and figure 2 As shown, a straightening device for large-scale and easily unstable aluminum alloy profiles includes a roller system 4 arranged oppositely, which is composed of 12 straightening rollers 3, and the straightening rollers 3 and straightening rollers The roller full-transmission driving device 6 is connected, and the 12 straightening rollers 3 are installed in the combined frame 1 in a manner of facing up and down. The 12 straightening rollers are all driving rollers; the upper end of the straightening roller 3 is provided with 6 There are four upper roller pressing devices 2, and four lower roller pressing devices 5 are arranged at the lower end of the straightening roller 3. The upper roller pressing device 2 and the lower roller pressing device 6 realize reverse bending adjustment, and straighten the profile along the entire length. s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com