Fully-automatic specially-shaped pipe straightening machine

A tube straightening machine and fully automatic technology, applied in the field of straightening machines, can solve the problems of inaccurate guarantee of straightening standards, restricting straightening operations, low operating efficiency, etc. The effect of increased precision and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

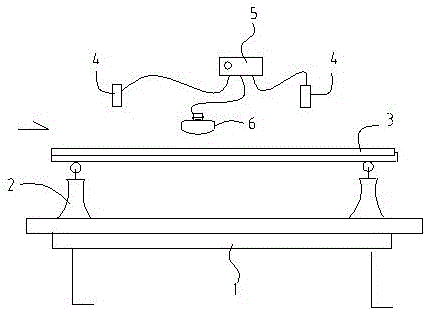

[0009] like figure 1 As shown, the fully automatic special-shaped pipe straightening machine in this embodiment includes a workbench 1 and a die mechanism 6 for straightening the special-shaped material 3. The workbench 1 is provided with two movable support points 2, two The movable supporting point 2 is used to laterally support the special-shaped pipe 3, and there are two distance laser detectors 4 above the workbench 1. The laser detector 4 is used to detect the distance between it and the special-shaped pipe 3 and transmit the detection data to the control center 5. The control center 5 finds out the bent part through calculation and controls the die mechanism 6 to straighten the bent part until the bend is eliminated.

[0010] The straightening machine with the above structure adopts a very high-precision laser distance detector to coop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com