Self-propelled automatic pressure straightening machine for gantry

A self-propelled, straightening machine technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of affecting the production efficiency and straightening accuracy of pressure straightening machines, low efficiency of steel turning and straightening, and floor space Large and other problems, to achieve the effect of convenient and quick straightening, simple structure, and reduced equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

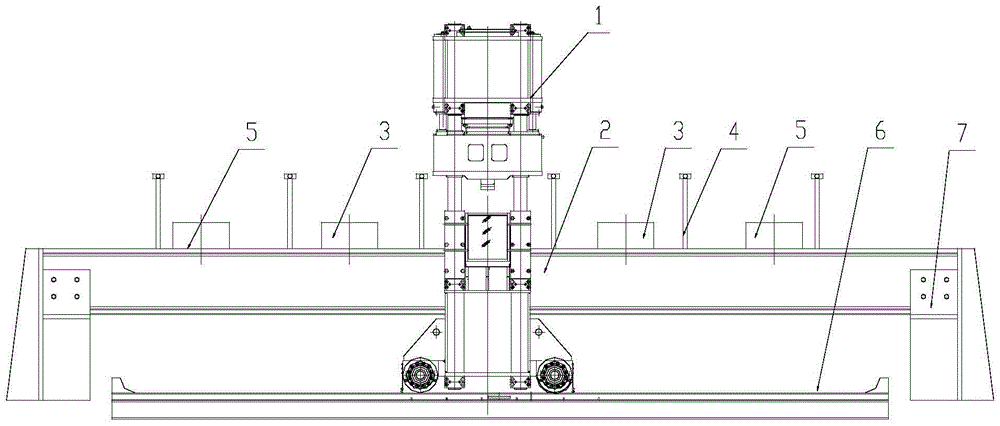

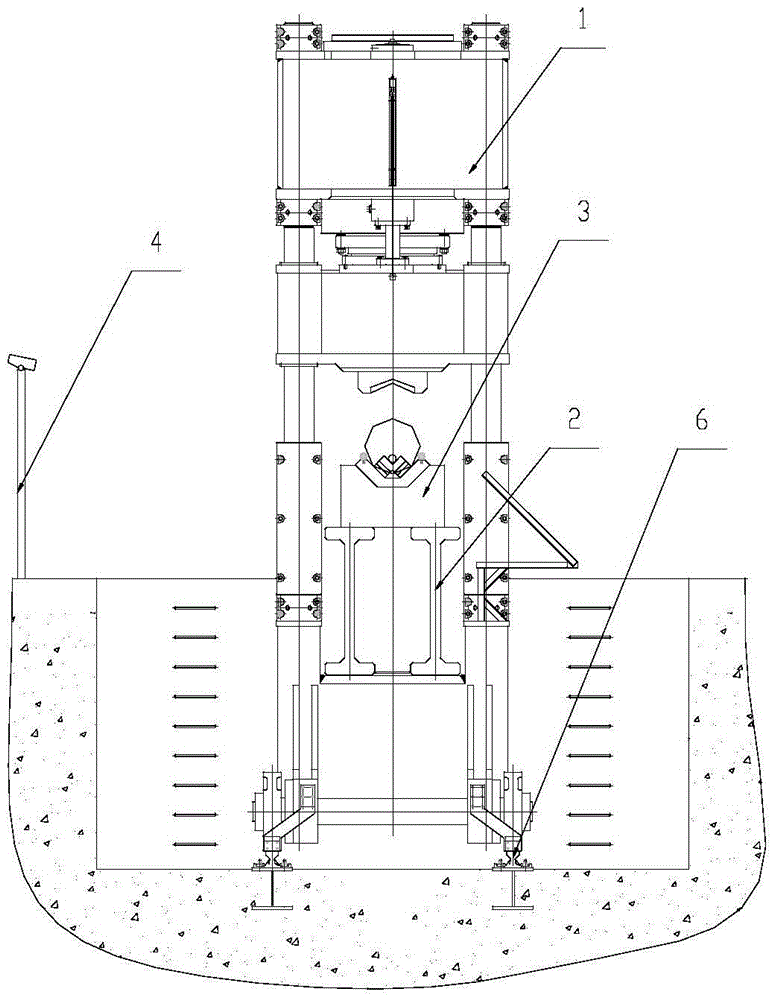

[0022] refer to figure 1 and figure 2 , a gantry self-propelled automatic pressure straightening machine, comprising a rail steel beam 2, the two ends of the rail steel beam 2 are installed on the base 7, the rail steel beam 2 passes through the gantry frame of the main machine 1 as a whole, and two moving anvils 3 and two moving steel turning devices 5 are all arranged on the track steel beam 2, and move in the track steel beam 2; The main engine 1 walks on the rail 6, the rail 6 is laid on the foundation, and the straightness detection system 4 is arranged beside the rail 6.

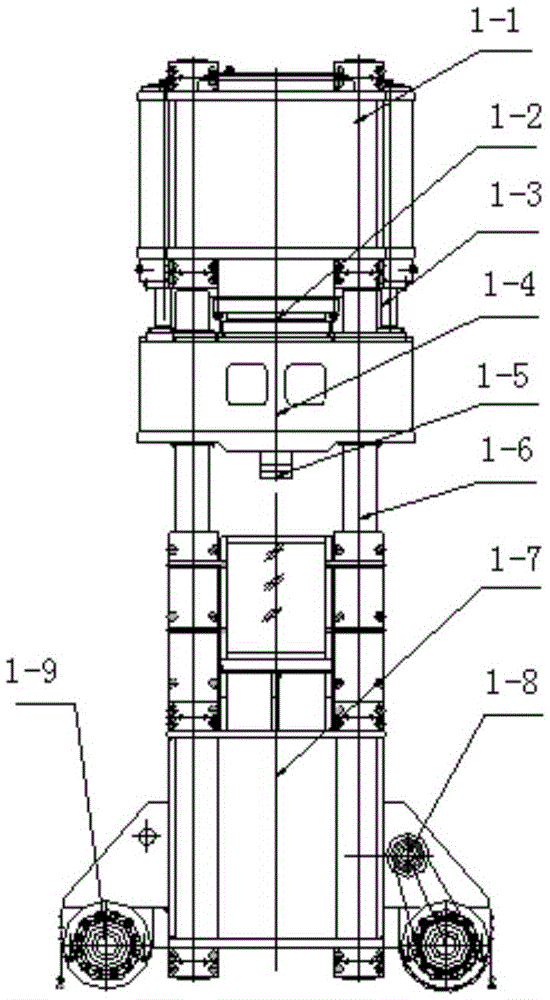

[0023] refer to image 3 , the main engine 1 is a gantry-type three-beam and four-column structure, the upper beam 1-1 and the lower beam 1-7 are tensioned as a whole by the column 1-6, and the main oil cylinder 1-2 and the auxiliary oil cylinder 1-3 are installed on the upper In the beam 1-1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com