Slight and flexible straightening device for small-diameter round tubes

A micro-quantity and small-diameter technology, applied in the field of metal material round pipe straightening equipment, can solve the problems of large straightening error, small pipe diameter, low production efficiency, etc., and achieve the effect of easy operation, low cost and high straightening accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

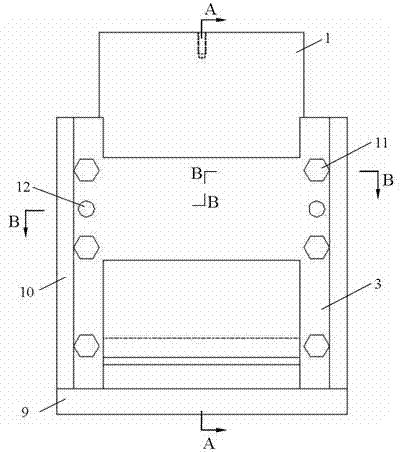

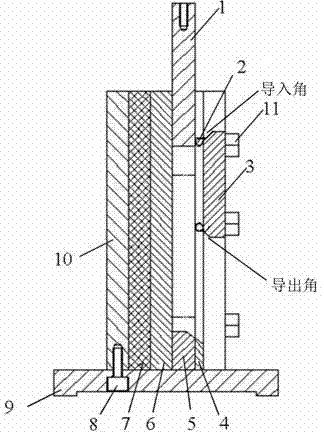

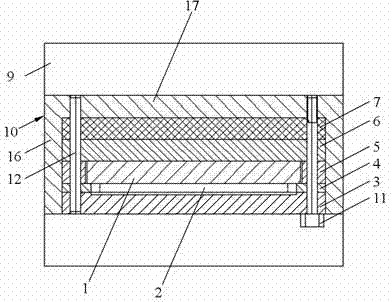

[0030] The following is a detailed description of the small-diameter circular tube micro-flexible straightening device of the present invention in combination with the accompanying drawings and examples:

[0031] Such as Figure 1~4 As shown, a small-diameter circular tube micro-flexible straightening device includes a base 9 and a limit frame 10 mounted on the base 9 through screws 8. The limit frame 10 has a U-shaped cross section and is composed of two side plates 16 Connected to the two sides of the backboard 17, the frame of the limit frame 10 is provided with an elastic pad 7, an intermediate pad 6 and a fixed washboard 3 in sequence, the elastic pad 7 is close to the backboard 17, and the longitudinal section of the fixed washboard 3 is H-shaped. A vertical plate 14 is connected to the two sides of the horizontal plate 13, and a partition plate 5 and a pipe diameter limit pad 4 are arranged between the two vertical plates 14 and the intermediary pad 6, and the partition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com