End-thickened steel-tube straightening device

A straightening machine and steel pipe technology, which is applied in the field of metal pipe finishing machinery and equipment, can solve technical difficulties and other problems, and achieve the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

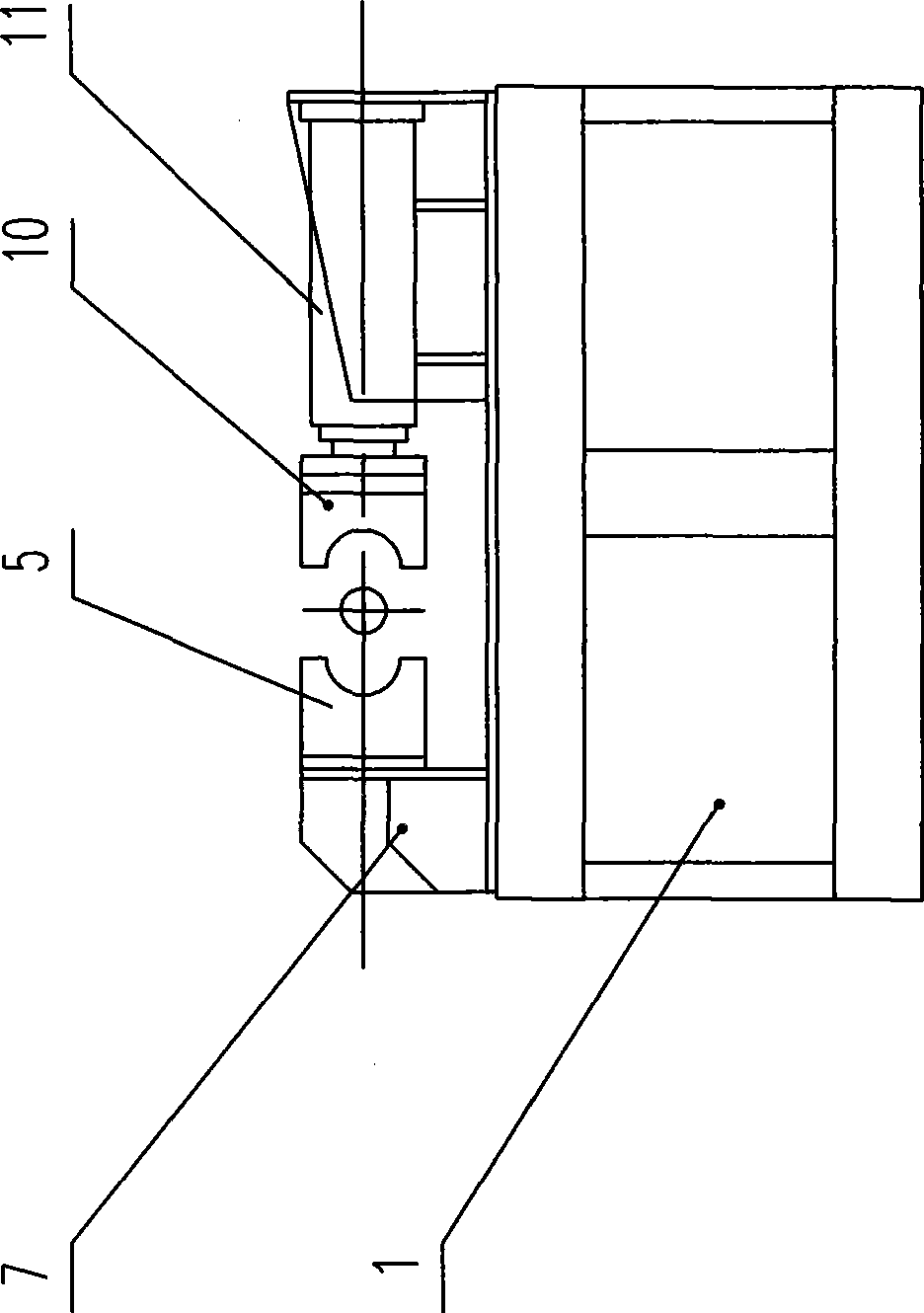

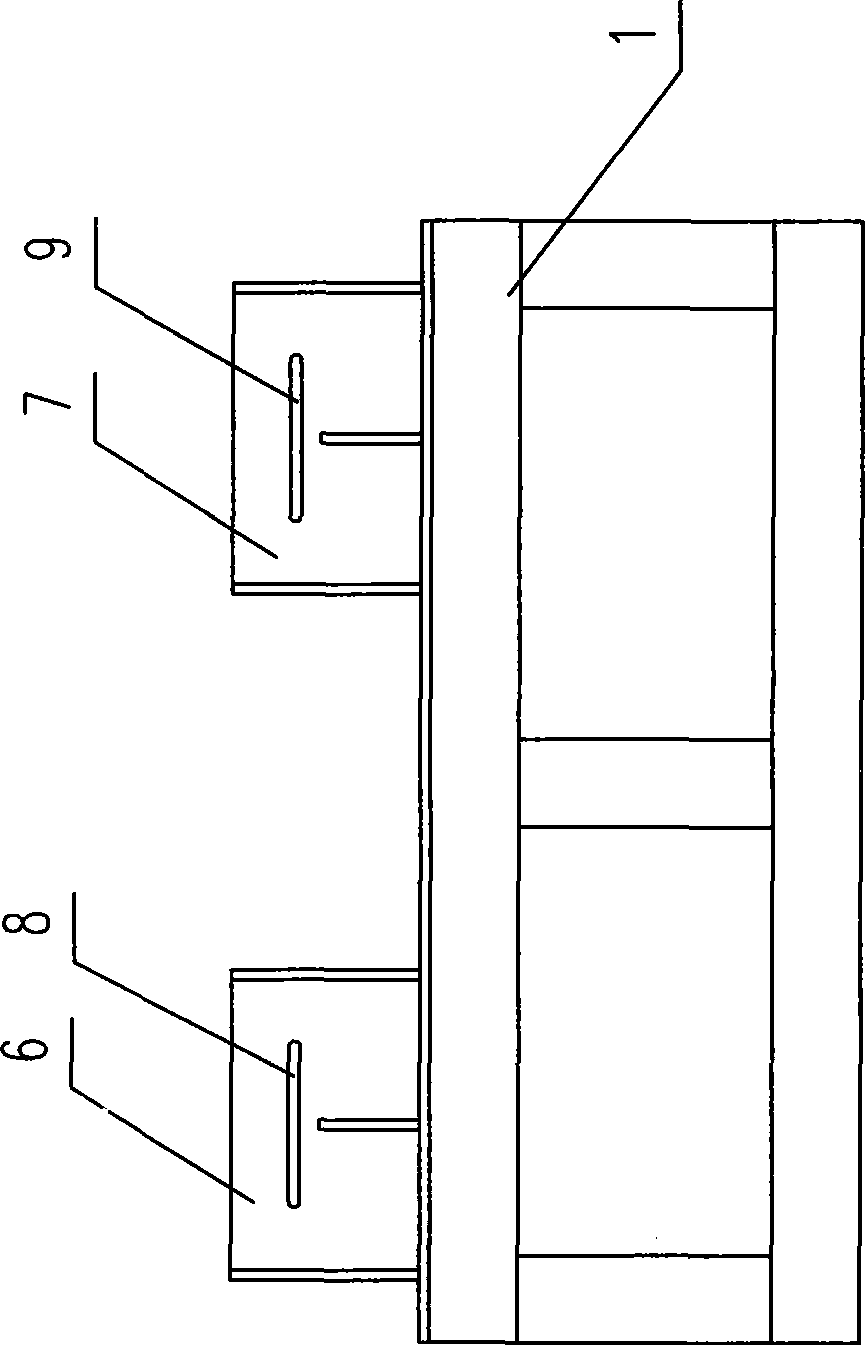

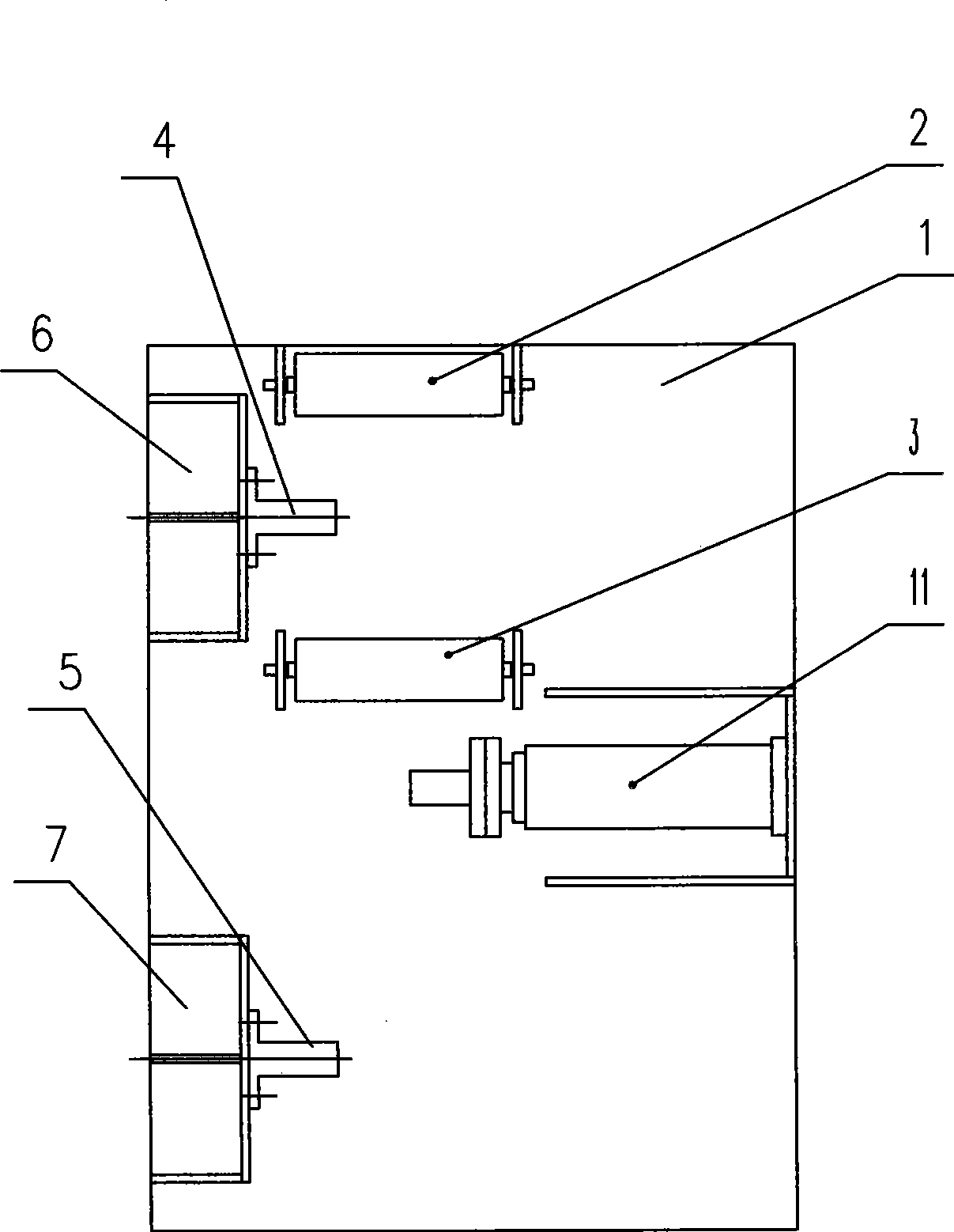

[0015] Such as figure 1 , 2 As shown in Figure 3, on a rectangular base 1, two sets of rollers 2, 3 are arranged along the length direction.

[0016] Two steel pipe fulcrum seats 4, 5 that can slide along the length of the pedestal 1 are respectively arranged on the same side along the length direction of the base 1, and a semicircular concave arc surface is provided on one side of each steel pipe fulcrum seat 4, 5. The specific method can be as follows: Weld and fix two transition blocks 6, 7 on the base 1, and respectively open long grooves 8, 9 on the same horizontal line on the two transition blocks 6, 7, and each of the long grooves 8, 9 is connected to the base. 1 The length direction is parallel. The steel pipe fulcrum seats 4 and 5 are respectively arranged on the inner side of the corresponding transition blocks 6 and 7, and the semi-circular concave arc backs of the steel pipe fulcrum seats 4 and 5 are fixed with connecting bolts. The bolts are connected to the long gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com