Elbow pressing-straight device

A tube bending and laser device technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems that affect production safety, cause safety hazards, and inaccurate results, so as to improve the accuracy of straightening and improve work efficiency , high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

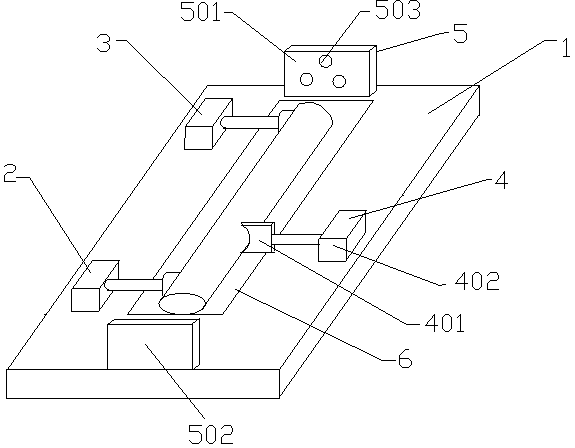

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, an elbow straightening device includes a base 1 , a left straightening support 2 , a right straightening support 3 , a straightening support 4 , a laser device 5 and a liner 6 . The liner 6 is arranged in the middle of the base 1 , the left straightening support 2 and the right straightening support 3 are arranged at both ends of one side of the liner 6 , and the straightening support 4 is arranged at the middle of the other side of the liner 6 .

[0014] The laser device 5 includes a laser emitting device 501 and a laser receiving device 502. The laser emitting device 501 is provided with three laser sources 503 facing the surface of the laser receiving device 502. The three laser sources 503 are distributed in a triangle and correspond to the inside of the cross section of the steel pipe respectively. Set close to the steel pipe wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com