Efficient straightening unit for small-bore thick-wall metal tubes

A metal pipe and small-diameter technology, which is applied in metal processing, metal processing equipment, forming tools, etc., can solve problems such as poor roundness straightening effect, high investment cost, damage to pipes and rolls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further illustrate the technical solution of the present invention, the present invention will be further described below through examples.

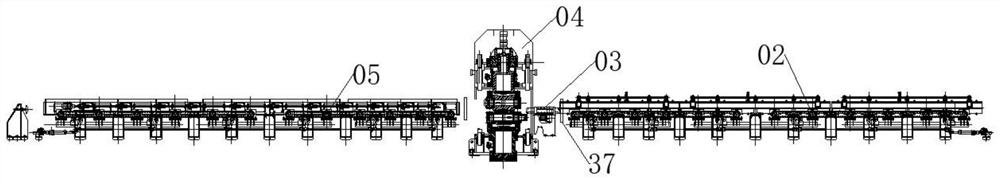

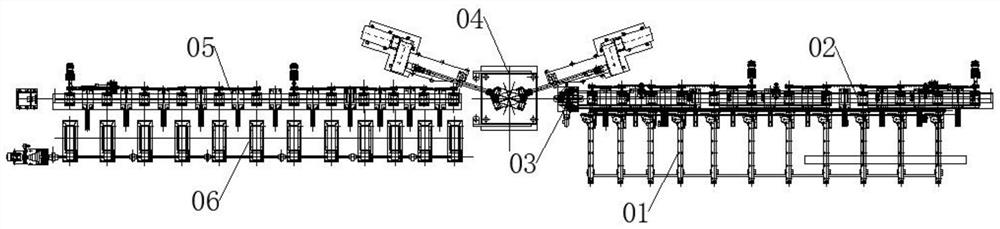

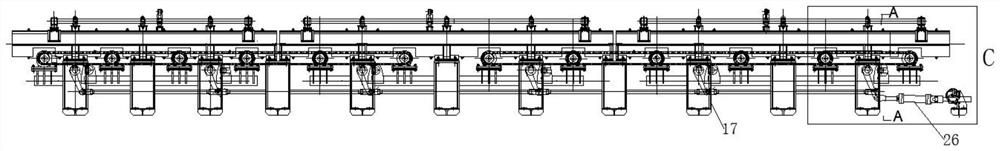

[0037] like figure 1 , figure 2 As shown, a high-efficiency straightening unit for small-diameter thick-walled metal pipes includes a feeding device 01, a feeding device 02, an inlet limit device 03, a straightening main machine 04, a discharging device 05, and a collecting device 06. The device 01 is arranged on one side of the feeding device 02, and is used to transport the unbundled pipes to be straightened to the feeding device 02, the feeding device 02, the inlet limiting device 03, the straightening main machine 04, and the discharging device 05 in sequence Arranged in a row, the feeding device 02 is used to deliver pipes to the straightening main machine 04, and the entrance limit device 03 arranged at the entrance of the straightening main machine 04 is used to guide the pipes entering the straightening main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com