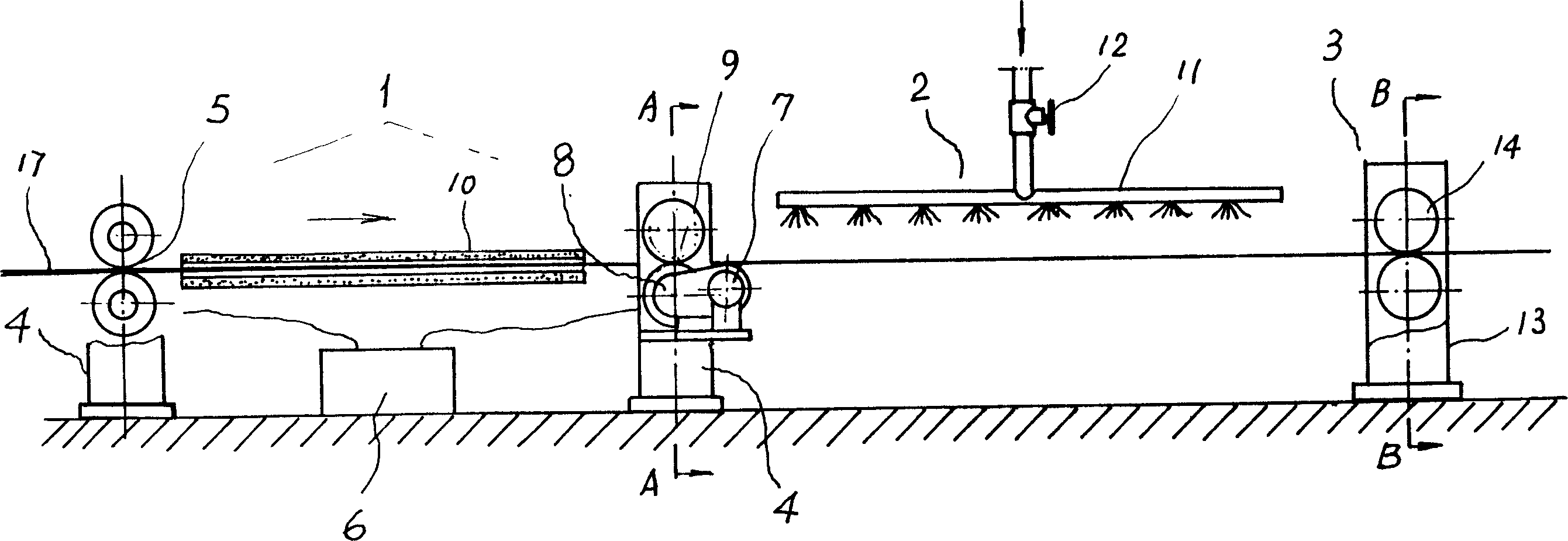

Composite working technology of steel wire heat treatment and straigthening and device thereof

A composite processing and electric heating device technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of difficulty in straightening steel wires with special-shaped cross-sections, difficulty in achieving consistency, and easy damage to the surface of steel wires. Improvement of physical properties and ease of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

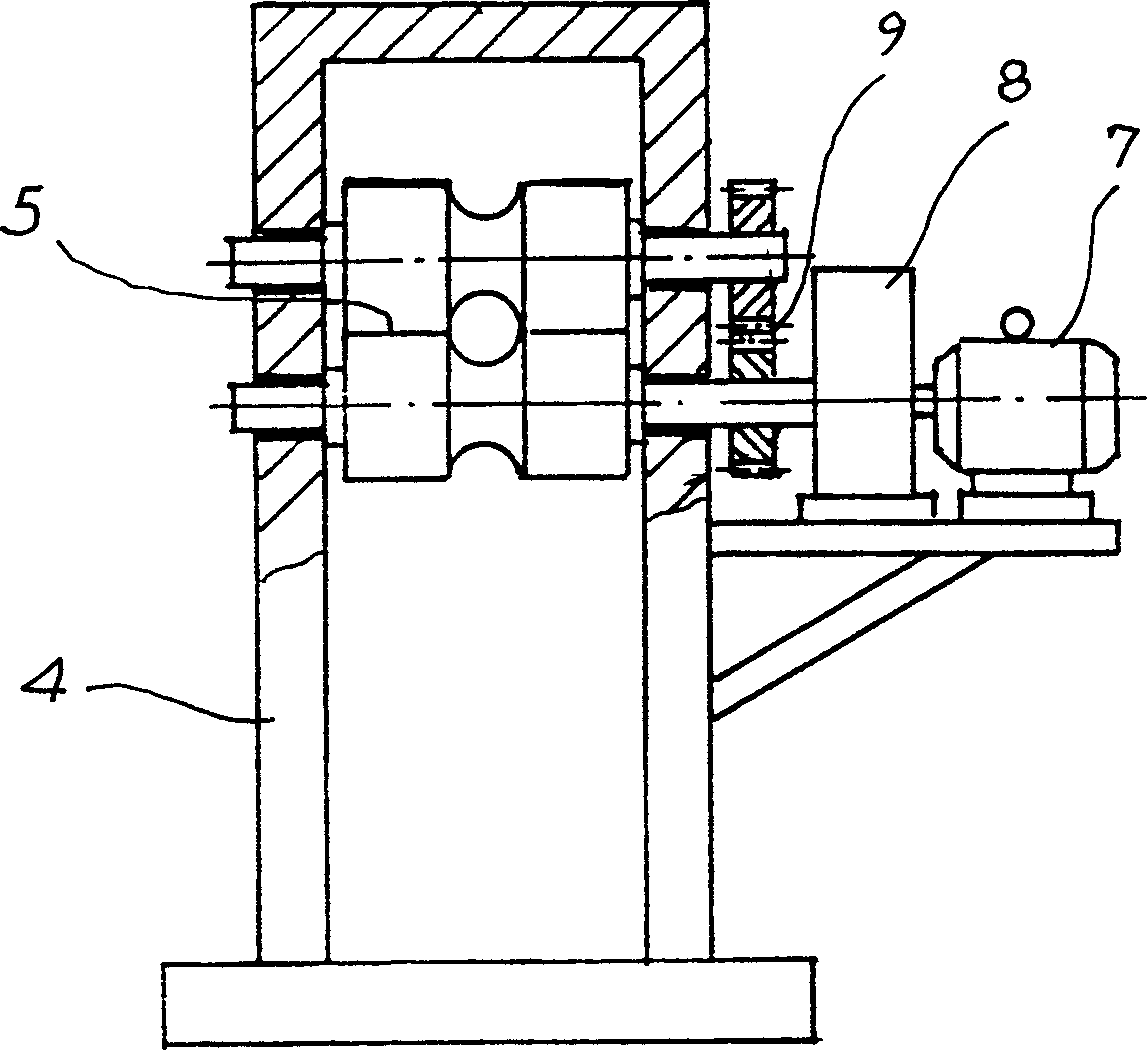

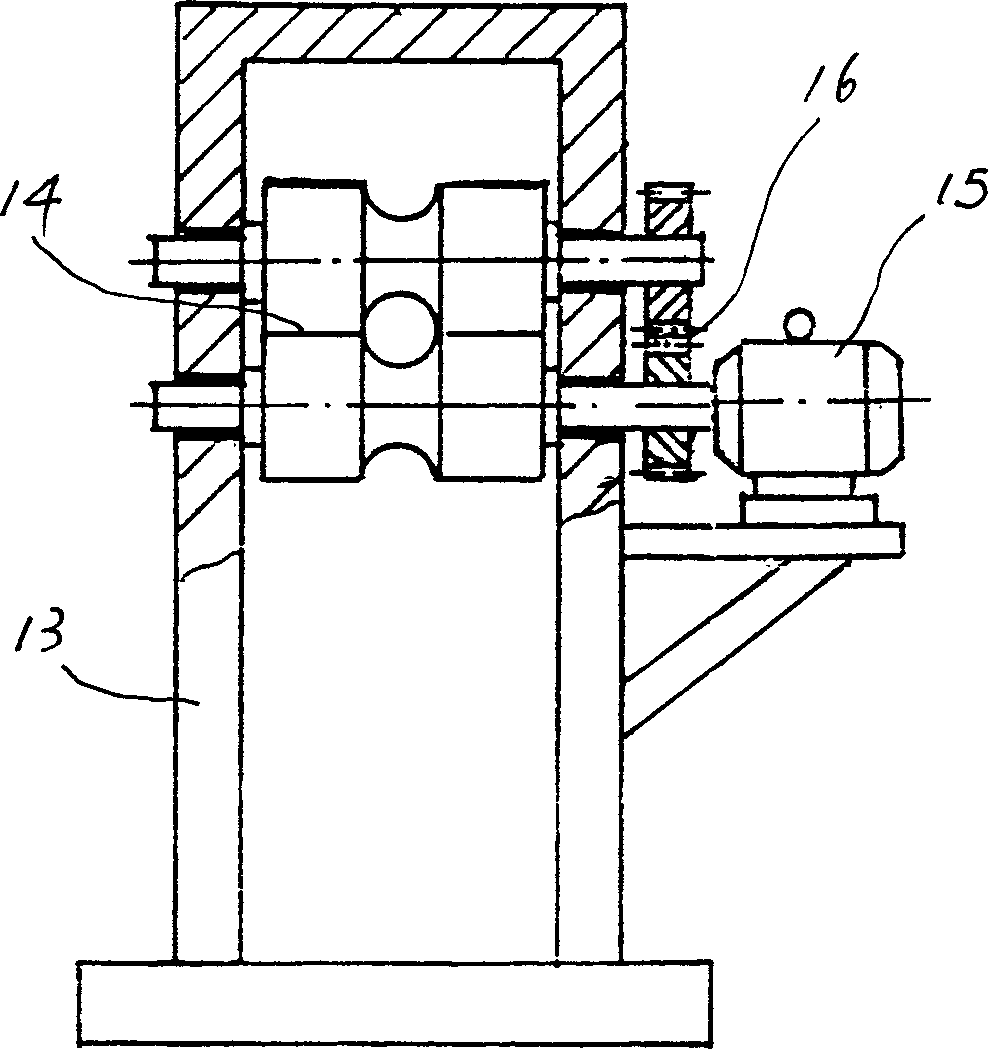

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Production of solid solution state φ5 mm SUS304 stainless steel wire straight strips: voltage is 50V, current is 500A, heating section length is 4 meters, maximum heating temperature is 1050°C, water cooling is used, tension is 20-50 kg, and wire speed is 8 m / min.

Embodiment 2

[0032] Embodiment 2: Production of hard φ6 mm GCr15 bearing steel straight strips: voltage 50V, current 800A, heating section length 4 meters, heating temperature 860°C, compressed air cooling, tension 40-70 kg, line speed 8 m / point. The cut steel wire is sent to the furnace for tempering.

Embodiment 3

[0033] Embodiment 3: Production of straight strips of SVS304 stainless steel wire with an elliptical cross-section of 4×705 mm in solid solution: voltage 40V, current 450A, length of heating section, heating temperature 1050°C, water cooling, tension of 20-50 kg, wire speed 8 m / min. After cutting, send it back to the stove for tempering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com