A heating device for powder paste filling and a powder paste production process using the device

A production process and heating device technology, applied in the field of powder paste production process and powder paste filling heating device, can solve the problems of easy generation of pits, powder paste cracks on the shrinking surface of the paste body, affecting the appearance and sales of the powder paste, and the like. Improve one-time forming rate, reduce thermal fatigue, smooth and beautiful surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

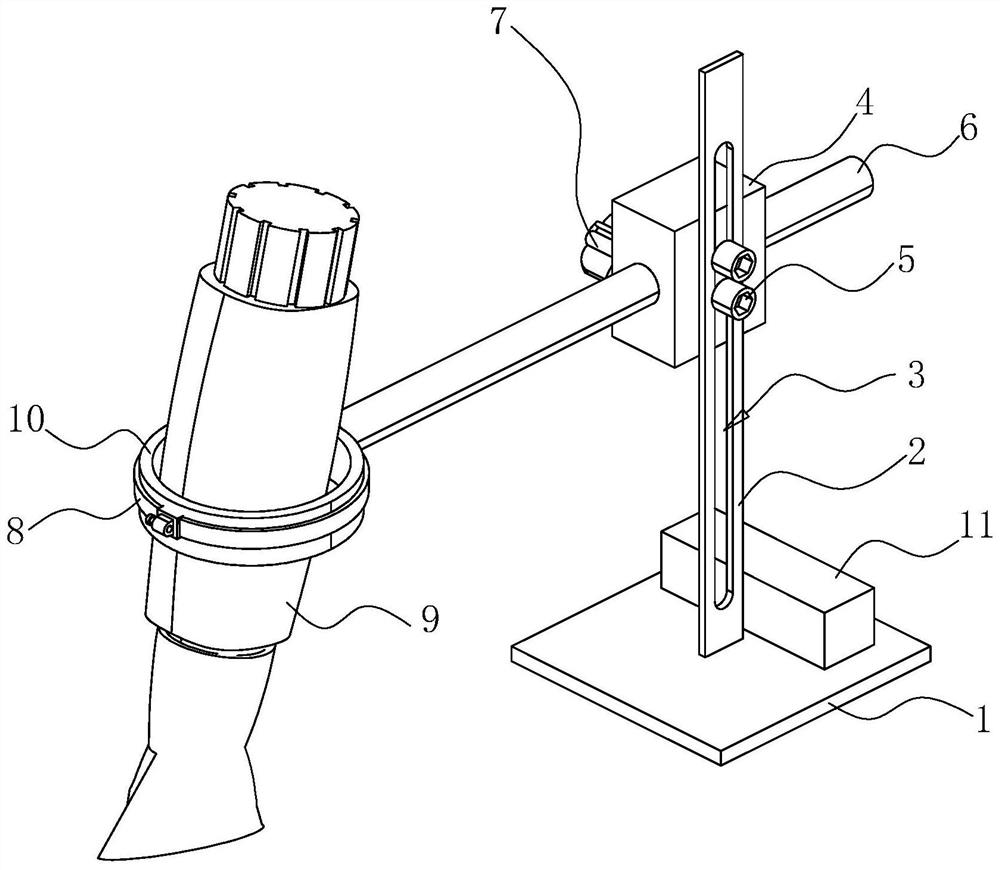

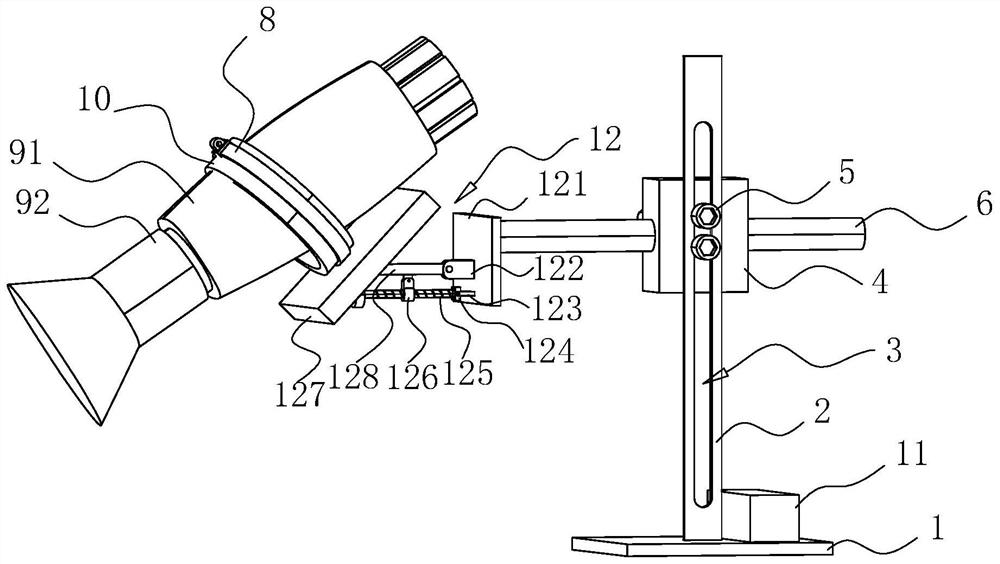

[0036] The implementation principle of Example 1 is: during the filling process of the powder paste, the container is heated by the heating device, so as to reduce the temperature difference between the container and the powder paste during the powder paste filling process, and improve the saturation of the powder paste in the container. At the same time, the cooperation between the positioning bolt 5 and the lifting block 4 can be used to adjust the installation height of the heating gun 9; the space between the positioning screw 7 and the sliding rod 6 can be used. The horizontal position of the heating gun 9 can be adjusted with a wide range of adjustment, and different containers can be heated.

[0037] A powder paste production process includes:

[0038] S1: Place the container on the fixture, apply oil to the container, and then preheat the container at a heating temperature of 80°C;

[0039] S2: Fill the container. The temperature of the powder paste is controlled at 85°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com