Fully automatic pipe fitting flanging equipment and flanging processing technology

A fully automatic, pipe fitting technology, applied in safety equipment, metal processing equipment, manufacturing tools, etc., can solve the problems that the appearance quality cannot be effectively improved, automation cannot be realized, and the proportion of defective products is high, so as to achieve outstanding quality and appearance, The effect of high one-shot molding rate and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

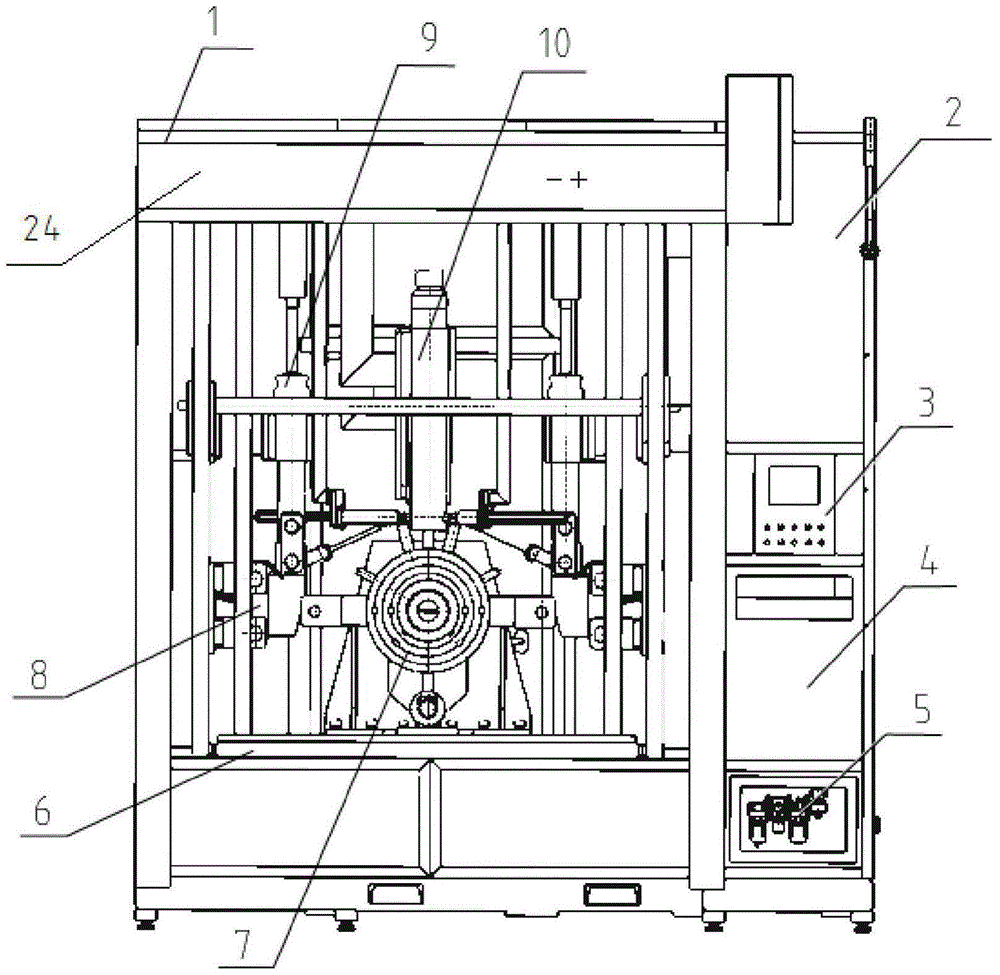

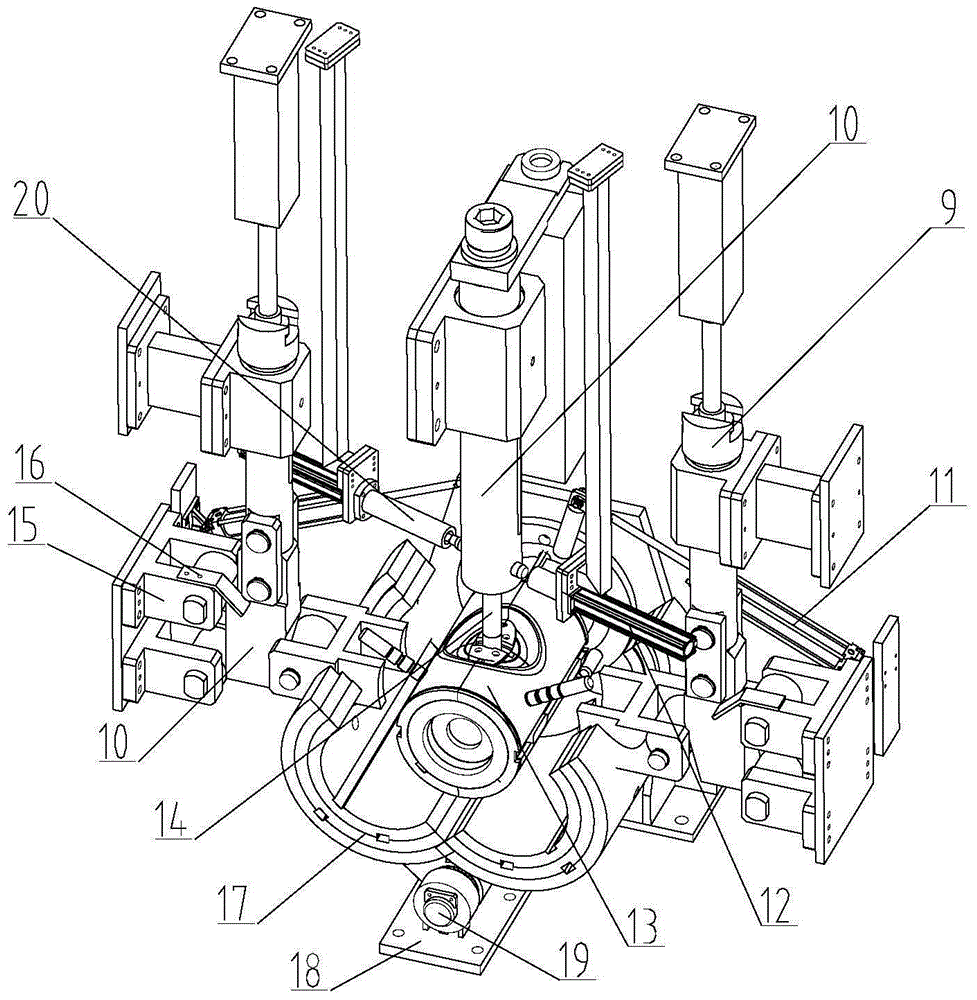

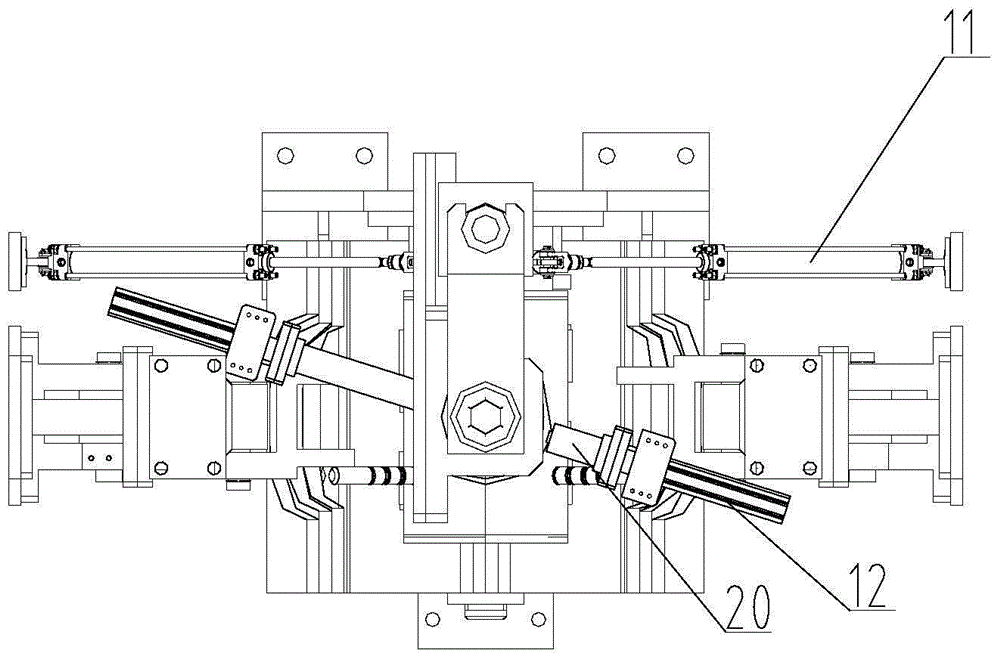

[0036] Such as Figure 1-4 As shown, the fully automatic pipe fitting flanging equipment includes a safety protection system, a hydraulic station 4, a pneumatic triple piece 5, a PLC controller 2, a power device, a pneumatic device, a dead point mechanism 8, a pressing device 7, a flange mechanism 14 and The workpiece positioning inner mold 13, the safety protection system includes a safety room 1, the safety room 1 is provided with a rolling door 24, the PLC controller 2, the hydraulic station 4 and the pneumatic triple unit 5 are arranged on the right side of the safety room 1, and in the safety room 1 Set the workbench 6, set the pressing device 7 on the workbench 6, the pressing device 7 is connected with the dead point mechanism 8 on both sides, set the workpiece positioning inner mold 13 in the pressing device 7, and set the flanging above the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com