Full-automatic seam buckling device

A fully automatic, buckle seam technology, applied in the field of sheet metal joints, can solve the problems of high proportion of defective products, difficulty in ensuring surface quality, and low work efficiency, so as to achieve good appearance quality of finished products, reduce processing costs, and once The effect of high molding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

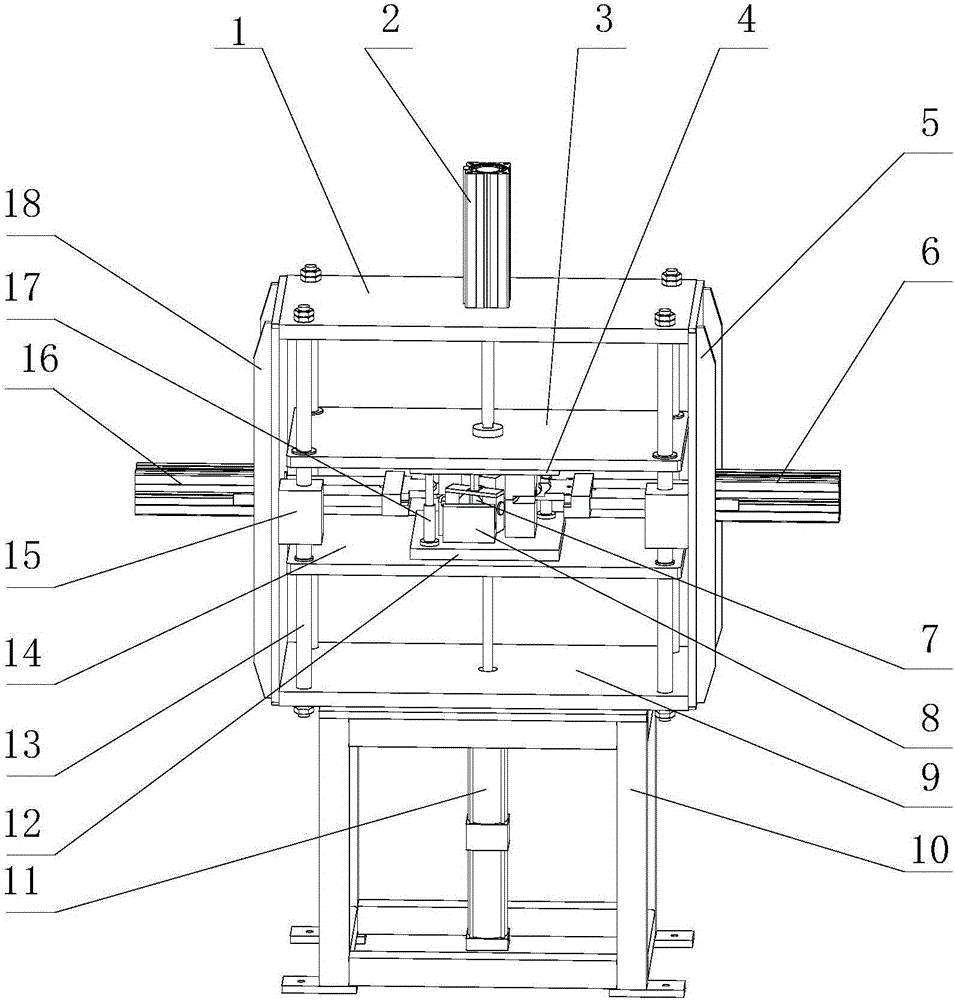

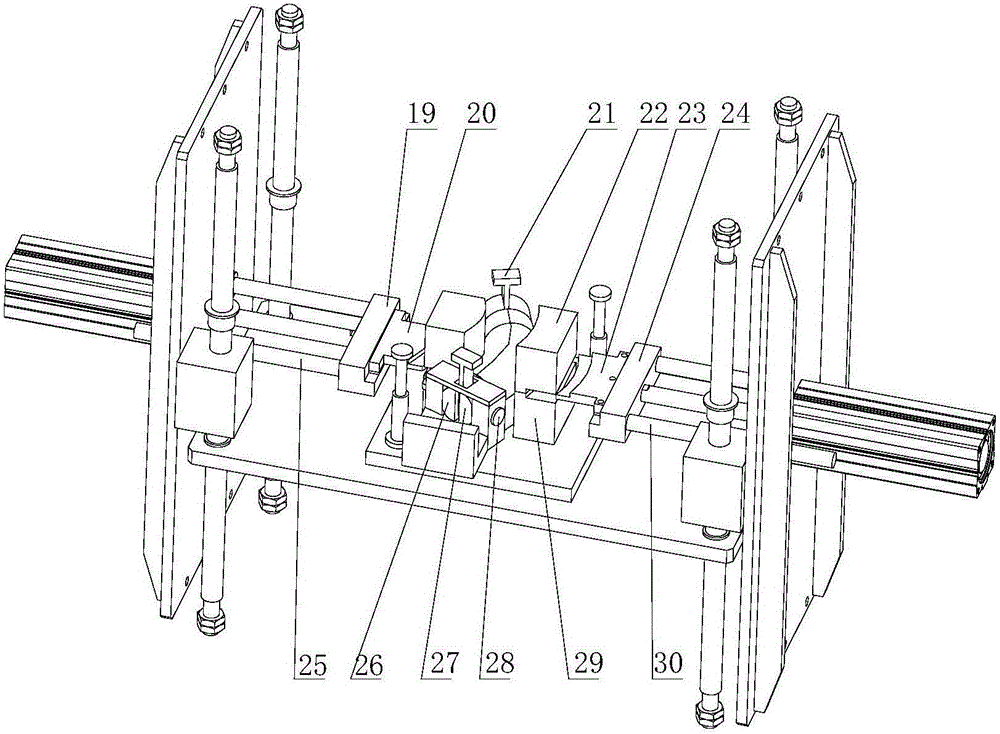

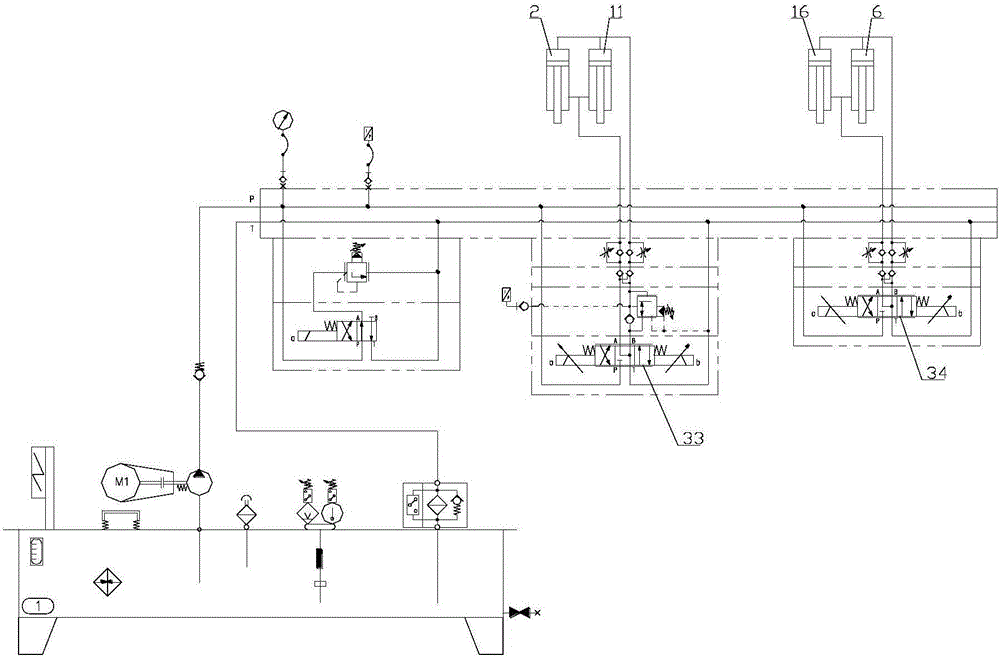

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0025] See Figure 1-Figure 2 , is a structural representation of the present invention. A fully automatic buckle seam device of the present invention comprises an upper mold mechanism, a lower mold mechanism, a left push mechanism, a right push mechanism, a mandrel and a control system, the upper mold 22 of the upper mold mechanism and the lower mold 29 of the lower mold mechanism They are arranged oppositely, and can be driven by the corresponding hydraulic cylinders 2 and 11 to realize the clamping action to bend the edge of the workpiece; 6 is driven to advance inwardly; the upper mold 22 and the lower mold 29 are split structures, and the shape of the split part is adapted to the shape of the core mold 7 placed therein, and the shape of the core mold 7 is adapted to the shape of the workpiece 31; Both sides of mold 22 and lower mold 29 clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com