End face tooth bell-shaped shell and manufacturing method thereof

A manufacturing method and bell-shaped shell technology, applied in the field of metal forming, can solve the problems of difficult machining of the end face of the shell, affecting the life of the final product, destroying the streamline of parts, etc., so as to increase the one-time forming rate, improve the appearance quality, reduce the The effect of deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] Nowadays, milling is generally used in the industry to process the end tooth shape of the end tooth bell-shaped shell, which not only wastes materials, but also destroys the streamline of parts during milling, affecting the life of the final product. Therefore, the present invention provides a face gear bell case and its manufacturing method to solve the above problems.

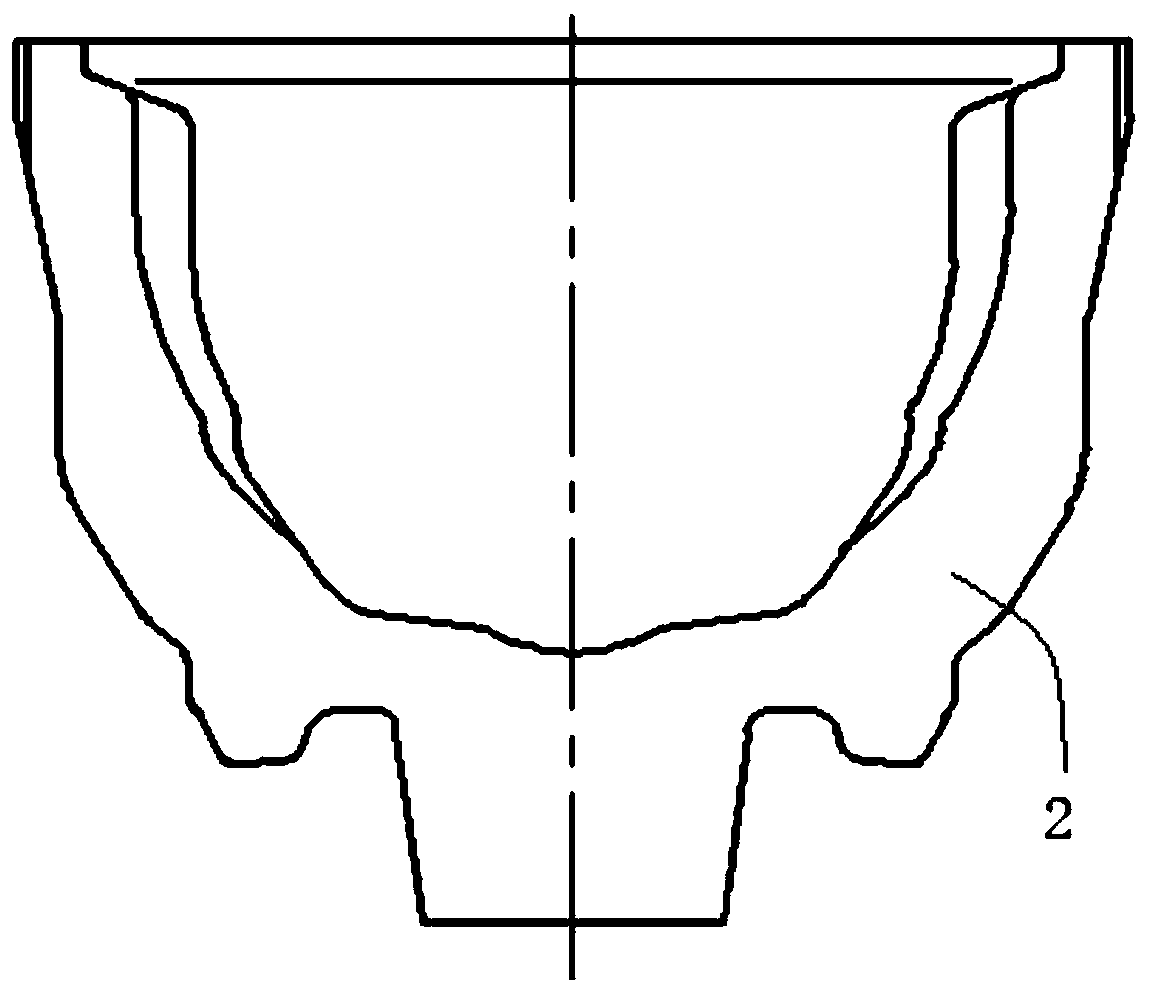

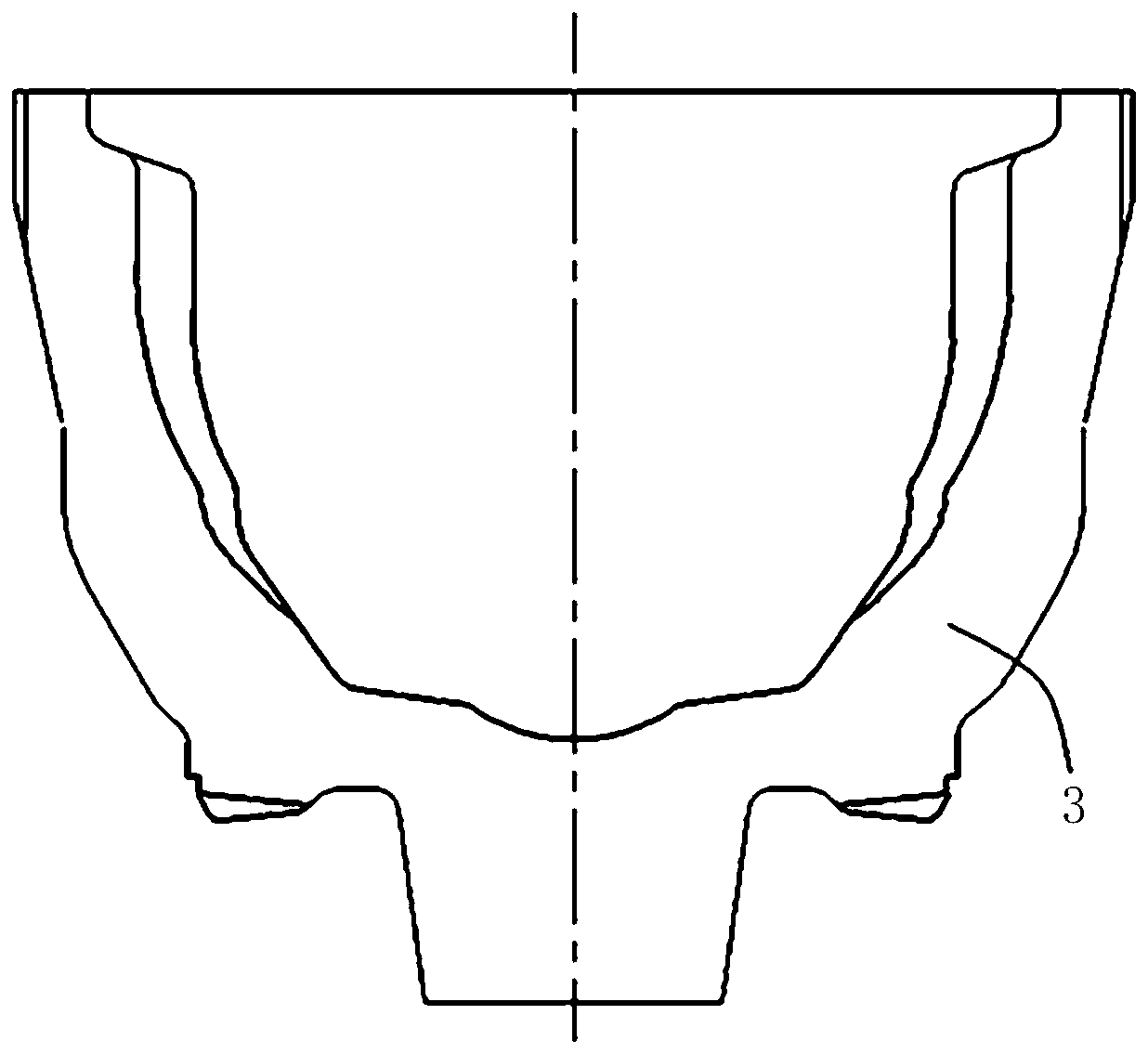

[0039] figure 1 It is a structural schematic diagram of the bar stock described in the present invention; figure 2 It is a schematic diagram of the end face of the blank described in the present invention; image 3 It is a schematic diagram of the end face of the blank with teeth according to the present invention; Figure 4 It is a schematic view of the end face of the bell-shaped shell of the end face gear in the present invention.

[0040] Please refer to Figure 1-4 , the present invention provides a kind of manufacturing method of face gear bell shell, comprises the following steps:

[0041]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com