Method and system for preparing calcium carbide

A calcium carbide and quicklime technology, applied in the direction of carbide, calcium carbide, etc., can solve the problems of unstable production process of calcium carbide furnace, too many pellets in calcium carbide furnace, etc. The effect of improving pellet strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

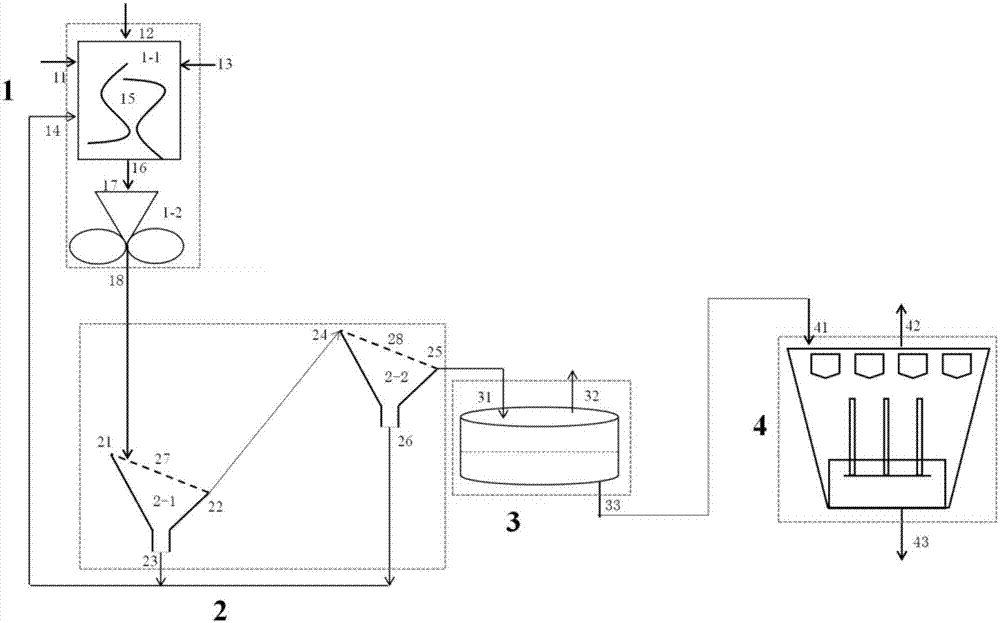

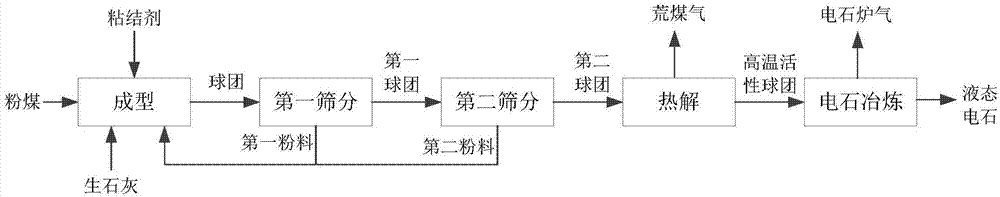

[0071] In this example, the figure 1 The system shown and figure 2 The shown method prepares calcium carbide, and concrete process is as follows:

[0072] The particle sizes of powdery medium-low rank coal and quicklime are shown in Table 2:

[0073] The raw material particle diameter of table 2 embodiment 1

[0074] raw material

-0.125mm

0.125-0.5mm

0.5-1.0mm

1.0-3.0mm

pulverized coal

45.7%

53.6

0.7%

-

quicklime

0.8%

39.7%

43.3%

16.2%

[0075] Mix the powdery medium-low rank coal, quicklime and binder uniformly in the intensive mixer (mixing device 1-1) and then place it in the pressure molding machine (ball pressing device 1-2) for extrusion molding, in which the hydraulic cylinder The pressure is 19MPa. The mass ratio of powdery medium-low rank coal, quicklime, and binder is 1.03:1:0.032.

[0076] The obtained pellets are first sieved by a 5×5mm first sieving device 2-1 and then conveyed by a belt, an...

Embodiment 2

[0080] In this example, the figure 1 The system shown and figure 2 The shown method prepares calcium carbide, and concrete process is as follows:

[0081] The particle sizes of powdery medium-low rank coal and quicklime are shown in Table 3:

[0082] The raw material particle diameter of table 3 embodiment 2

[0083] raw material

-0.125mm

0.125-0.5mm

0.5-1.0mm

1.0-3.0mm

pulverized coal

54.3%

45.1

0.6%

-

quicklime

2.0%

31.0%

47.5%

19.5%

[0084] The particle size of the powdery medium-low rank coal is ≤1mm, and the particle size of the quicklime is ≤3mm. The powdery medium-low rank coal, quicklime and binder are mixed uniformly in the intensive mixer (mixing device 1-1) and placed in the Extrusion molding in the pressure molding machine (ball pressing device 1-2), wherein the pressure of the hydraulic cylinder is 19MPa. The mass ratio of powdery medium-low rank coal, quicklime, and binder is 0.8:1:0.024. ...

Embodiment 3

[0089] In this example, the figure 1 The system shown and figure 2 The shown method prepares calcium carbide, and concrete process is as follows:

[0090] The particle sizes of powdery medium-low rank coal and quicklime are shown in Table 4:

[0091] The raw material particle diameter of table 4 embodiment 3

[0092] raw material

-0.125mm

0.125-0.5mm

0.5-1.0mm

1.0-3.0mm

pulverized coal

54.3%

45.1

0.6%

-

quicklime

2.0%

31.0%

47.5%

19.5%

[0093] The particle size of powdery medium-low rank coal is ≤0.5mm, and the particle size of quicklime is ≤1mm. Mix powdery medium-low rank coal, quicklime and binder in a strong mixer (mixing device 1-1) and place Extruded in a pressure molding machine (ball pressing device 1-2), wherein the pressure of the hydraulic cylinder is 19MPa. The mass ratio of powdery medium-low rank coal, quicklime, and binder is 1.2:1:0.029.

[0094] The obtained pellets are first sieved by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com