Injection mold for automobile door frame

A technology of injection molds and molds, which is applied in the field of injection molds for car door frames, can solve the problems of easy deformation of plastic parts, achieve the effects of preventing mold bubbles, reducing processing costs, and improving one-time molding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

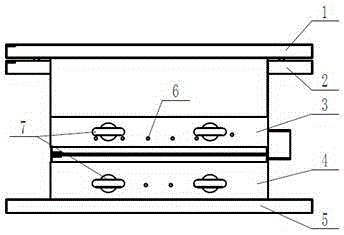

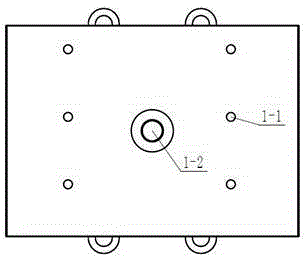

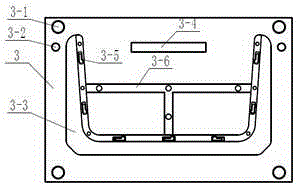

[0015] Depend on figure 1 , figure 2 Known, a kind of door frame injection mold of the present invention, by upper fixing plate 1, pouring hole 1-1, connection fixing hole 1-2, upper mold holder 2, upper mold 3, lower mold 4, lower mold holder 5, cooling water channel 6. Composed of lifting lugs 7, the lower mold 4 is fixed above the lower mold base 5, the upper fixing plate 1 is fixed above the upper mold base 2, the upper mold 3 is fixed below the upper mold base 2, and the upper mold 3 and the lower mold 4 are arranged There is a mold base guide column 3-1, through the mold base guide column 3-1, the upper mold 3 and the lower mold 4 can perform relatively stable mold opening and closing actions, and the upper mold 3 and the lower mold 4 are equipped with multi-circuit cooling water channels 6. An injection molding machine connection and fixing hole 1-2 is provided at the center of the upper fixing plate 1, with the longitudinal axis of the connection and fixing hole 1-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com