Plasma processing equipment

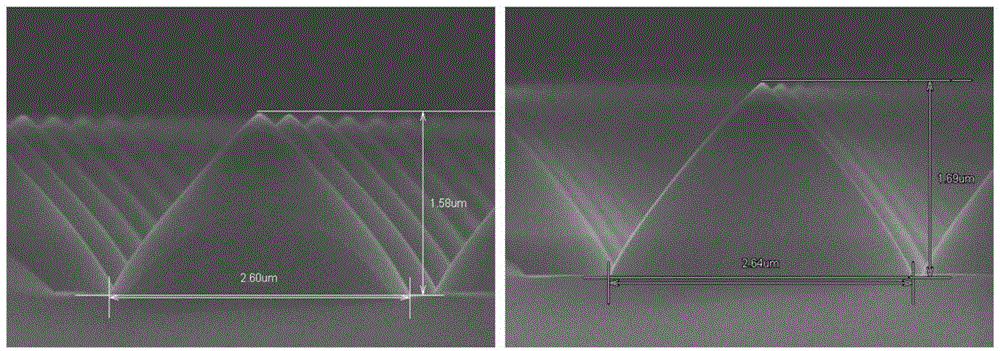

A processing equipment and plasma technology, applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problems of poor etching uniformity, residual corners or arc structures, and difficulty in forming triangular shapes, so as to reduce density and increase The thickness of the sheath, the effect of improving the uniformity of etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order for those skilled in the art to better understand the technical solutions of the present invention, the plasma processing equipment provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

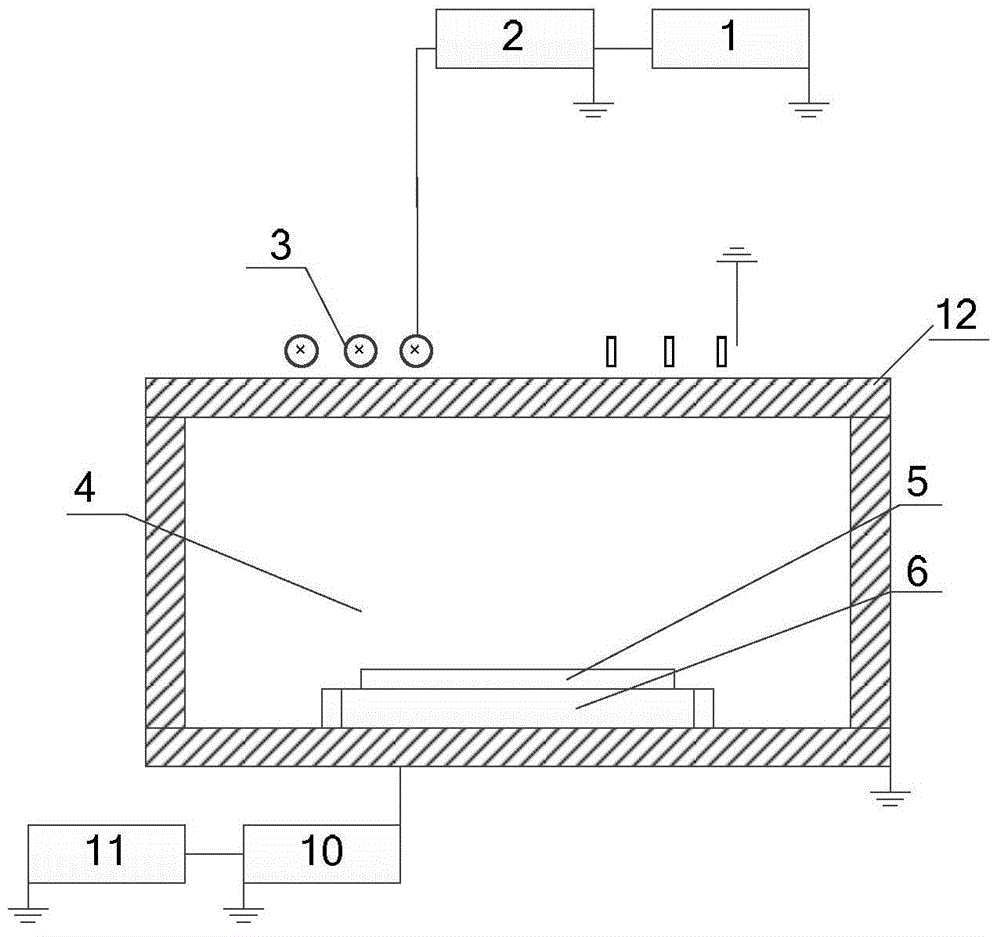

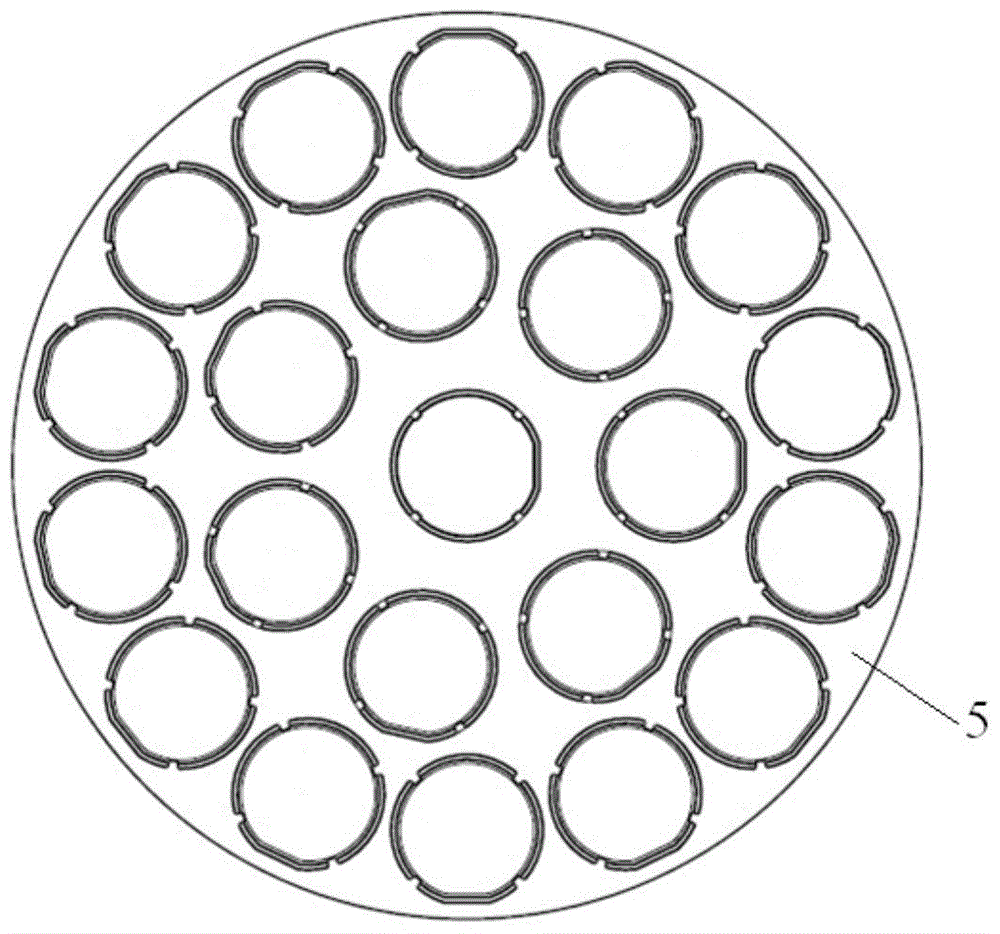

[0035] The plasma processing equipment provided by the present invention includes a reaction chamber, a base for carrying workpieces to be processed, and a radio frequency antenna device for exciting the reaction gas in the reaction chamber to form plasma. The radio frequency antenna device includes an inductance coil, an electrode The plate group and the radio frequency source, wherein the inductance coil and the electrode plate group are connected in parallel with each other and are electrically connected to the radio frequency source. When the radio frequency source is turned on, it simultaneously loads radio frequency power to the inductance coil and the electrode plate group, and the inductance coil adopts inducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com