Linear permanent-magnet generator

A permanent magnet generator and linear technology, applied in the direction of synchronous machines, electrical components, electromechanical devices, etc., can solve the problems of energy loss of intermediate mechanisms, complex generator structure, low power generation efficiency, etc., to reduce harmonic components, Simplified structure and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

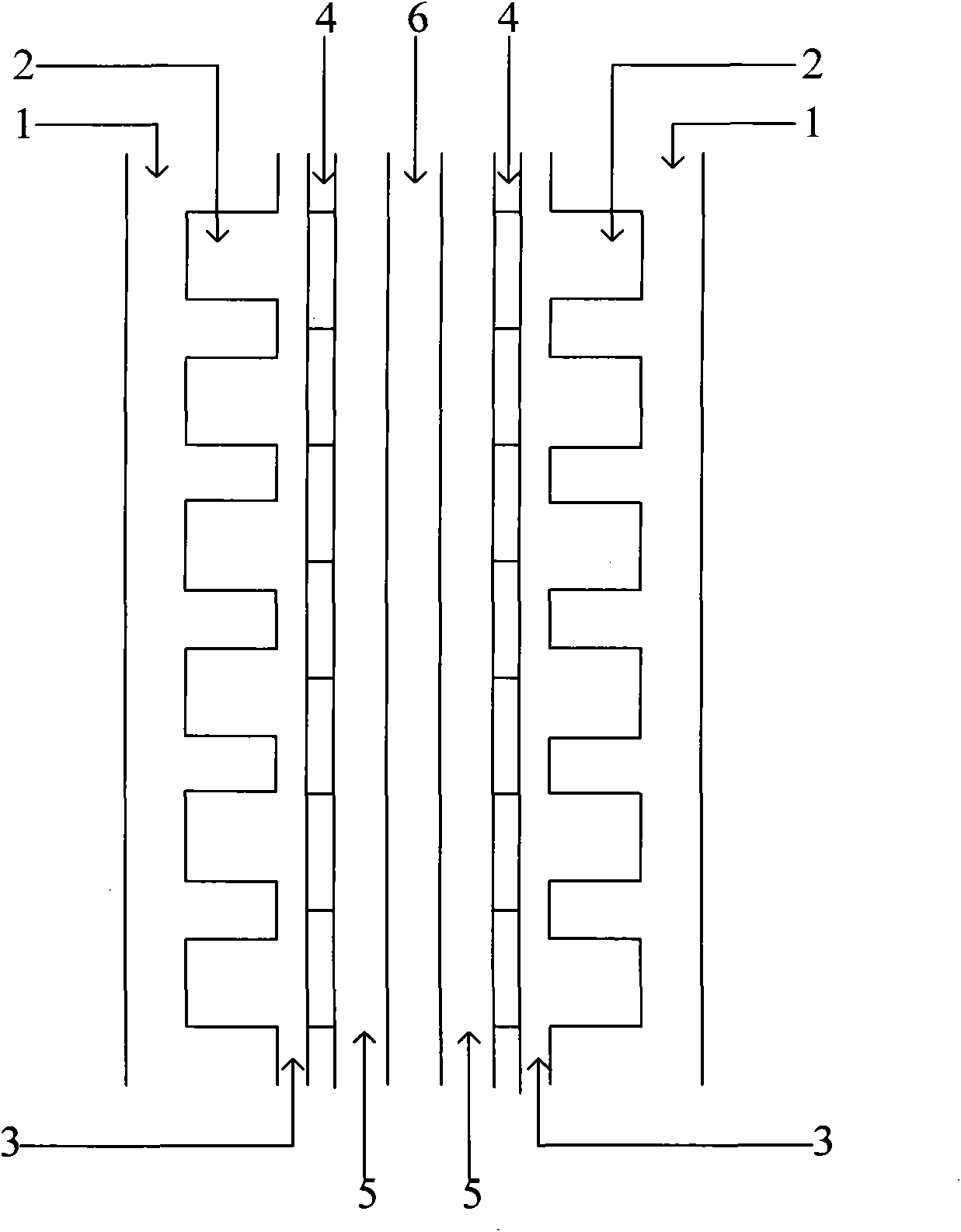

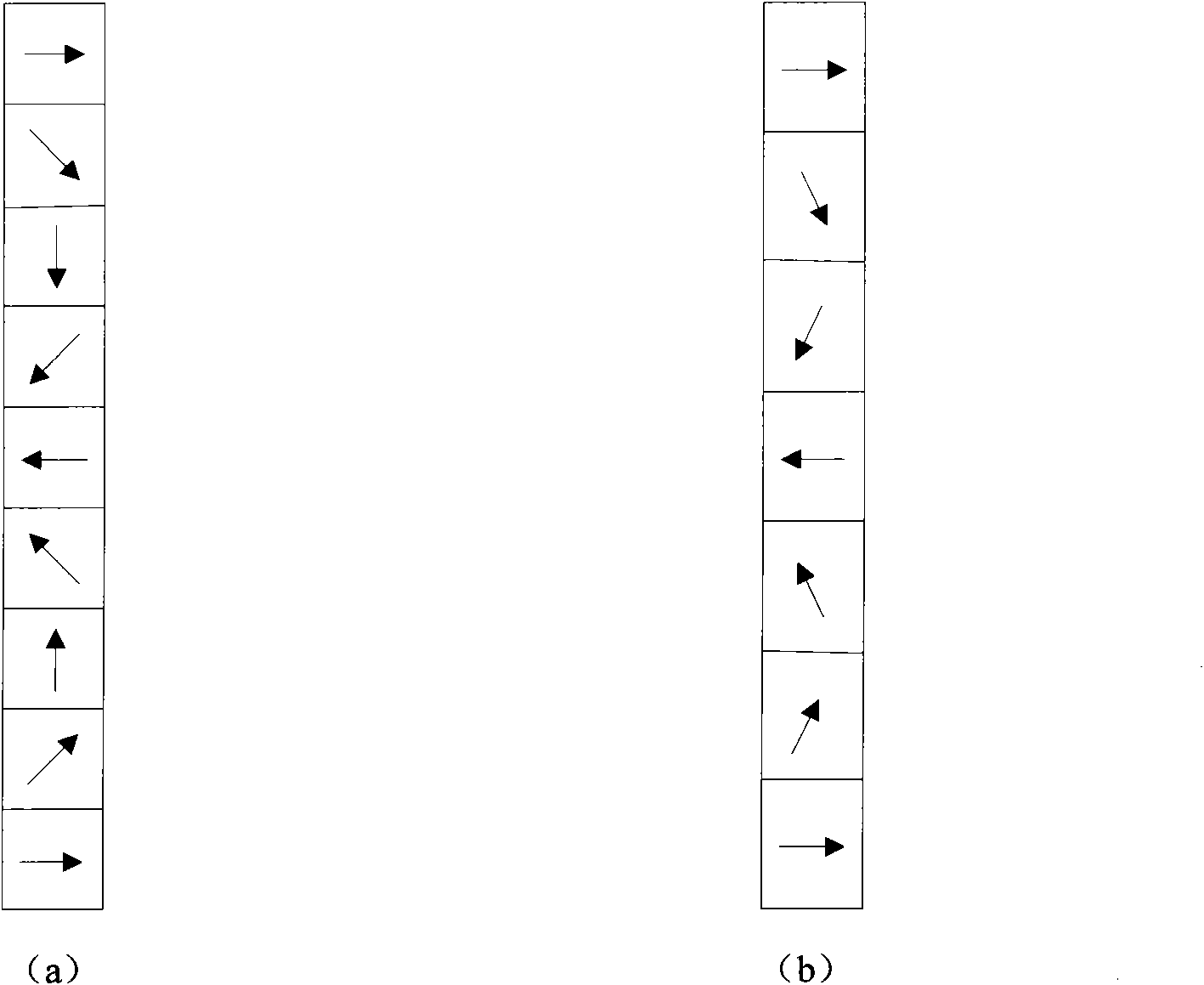

[0017] The present invention makes the secondary inner layer of the cylindrical linear generator use non-magnetic material, then surrounds it with ferromagnetic material on the non-magnetic material, and then installs the Halbach permanent magnet array on the surface of the ferromagnetic material, such as figure 1 shown. Among them, 1 is the primary core, 2 is the primary winding, 3 is the air gap between the permanent magnet array and the primary winding, 4 is the Halbach permanent magnet array, 5 is the secondary core, and 6 is the axis of the secondary non-magnetic material.

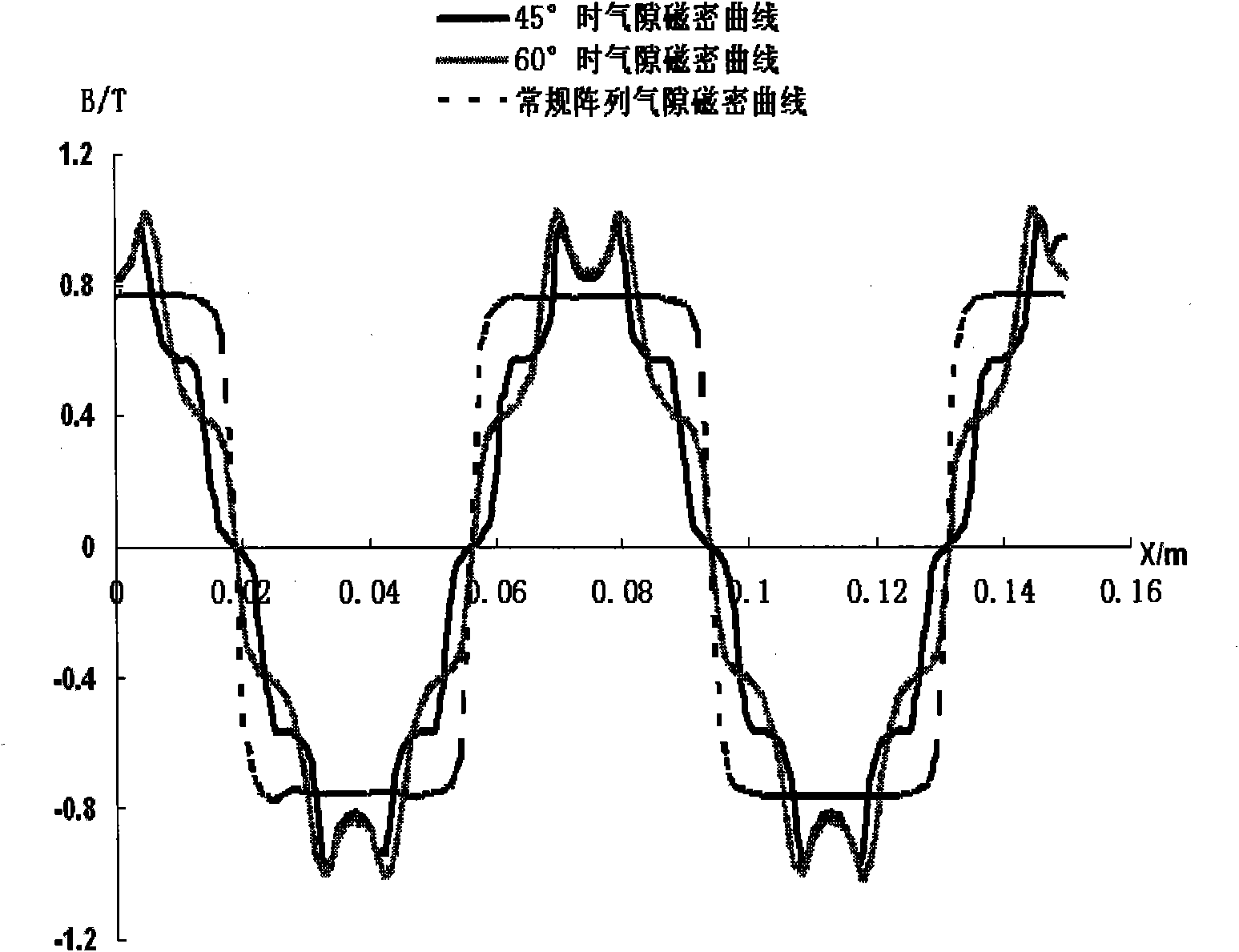

[0018] Since the magnetic field generated by the Halbach permanent magnet array is unilateral, the magnetic induction B of the secondary iron core is very small, so the eddy current loss caused in the secondary iron core is very small; and a strong magnetic field is generated in the air gap, Therefore, the induced electromotive force generated under the same permanent magnet material is large, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com