High-directional-thermal-conductivity carbon/polymer composite material and preparation method

A composite material and polymer technology, applied in the field of carbon/polymer composite materials and preparation, can solve the problems of large interface thermal resistance, low thermal conductivity, limited thermal conductivity of composite materials, etc., to achieve excellent comprehensive performance, high thermal conductivity, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

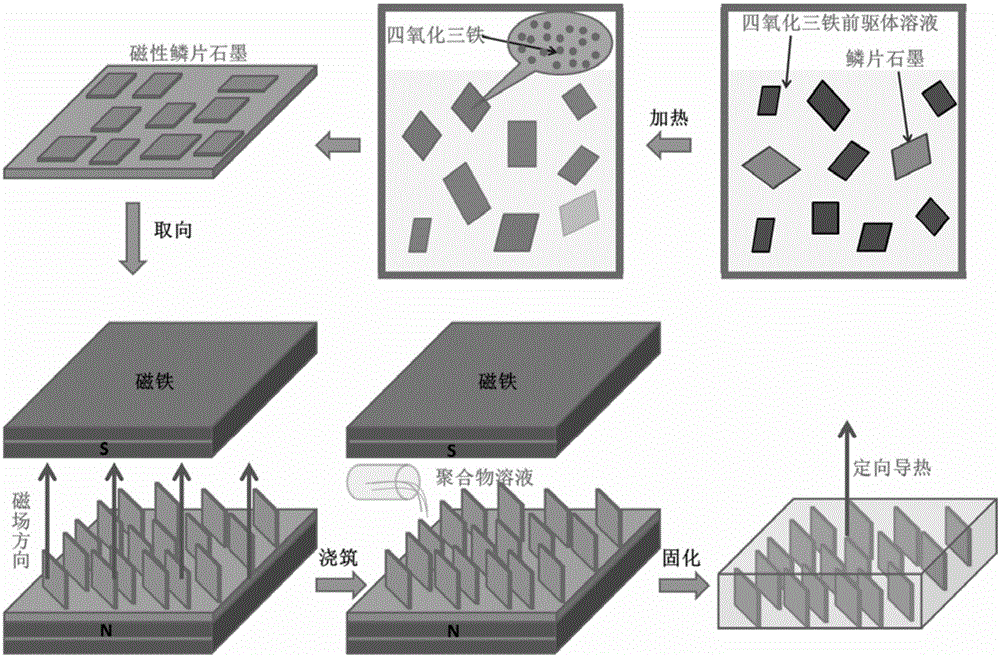

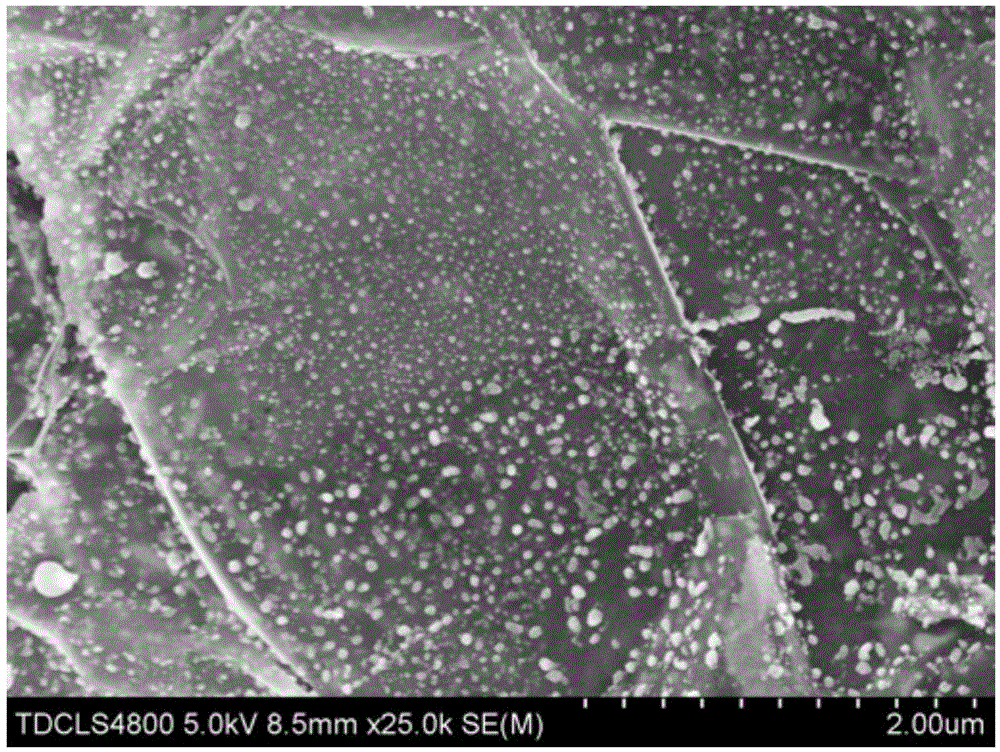

[0027] Prepare 100 g of iron ferric oxide precursor solution (ferric nitrate) with a mass fraction of 0.05% iron, weigh 0.05 g of flake graphite and add it to the above ferric nitrate solution and mix evenly, react at 20°C for 1 hour, filter, wash and dry Finally, the magnetic flake graphite in which ferric oxide is uniformly dispersed on the surface of the flake graphite is obtained. Place the above-mentioned magnetic flake graphite in a 1T magnetic field, wherein the direction from N to S poles of the magnetic field is perpendicular to the horizontal plane, and the magnetic flake graphite is oriented along the direction of the magnetic field, that is, the direction perpendicular to the horizontal plane to obtain a flake graphite array, and then pour polyester solution, after solidification A carbon / polymer composite material in which graphite flakes are oriented in polyester is obtained, wherein the mass fraction of graphite flakes is 15%. Test its directional thermal conduc...

Embodiment 2

[0029] The mass fraction of preparing iron is 100g of ferroferric oxide precursor solution (ferrous sulfate) of 0.05%, takes by weighing flake graphite 5g and adds above-mentioned ferrous sulfate solution and mixes, and reacts at 200 ℃ for 5 hours, filters, washes, After drying, the magnetic flake graphite in which ferric iron tetroxide is evenly dispersed on the surface of the flake graphite is obtained. Place the above-mentioned magnetic flake graphite in a magnetic field of 0.1T, wherein the direction from N to S poles of the magnetic field is parallel to the horizontal plane, and the magnetic flake graphite is oriented along the direction of the magnetic field, that is, the direction parallel to the horizontal plane to obtain a flake graphite array, and then pour polyamic acid solution. After curing, a carbon / polymer composite material in which graphite flakes are oriented in polyamide is obtained, wherein the mass fraction of graphite flakes is 40%. Test its directional t...

Embodiment 3

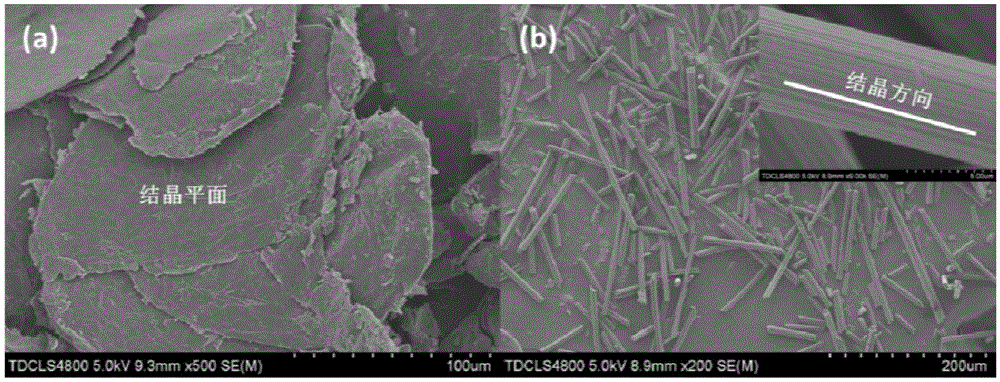

[0031] Prepare 100g of iron ferric oxide precursor solution (ferric sulfate) with a mass fraction of 5% iron, weigh 10g of carbon fiber, add the above ferric sulfate solution and mix evenly, react at 50°C for 12 hours, filter, wash and dry to obtain A magnetic carbon fiber in which Fe3O4 is evenly dispersed on the surface of the carbon fiber. Place the above-mentioned magnetic carbon fibers in a magnetic field of 0.3T, where the direction from N to S poles of the magnetic field is perpendicular to the horizontal plane, and the magnetic carbon fibers are oriented along the direction of the magnetic field, that is, the direction perpendicular to the horizontal plane to obtain a carbon fiber array, and then pour polyimide acid solution and cure Finally, a carbon / polymer composite material in which carbon fibers are aligned in polyimide is obtained, wherein the mass fraction of carbon fibers is 10%. Test its directional thermal conductivity, its thermal conductivity along the vert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com