A method of loading easily sublimable substances in porous materials

A technology of porous materials and substances, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems of harsh process conditions, long load time, difficult to realize automatic process, etc., to achieve high load, cooling Fast, easy to automate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Pretreatment of the acetylene black porous carbon material and the used container conduit: wash 1 g of the acetylene black porous carbon material and the used container and conduit with deionized water and put them in a blast drying oven to dry at 80°C 10h, remove surface moisture;

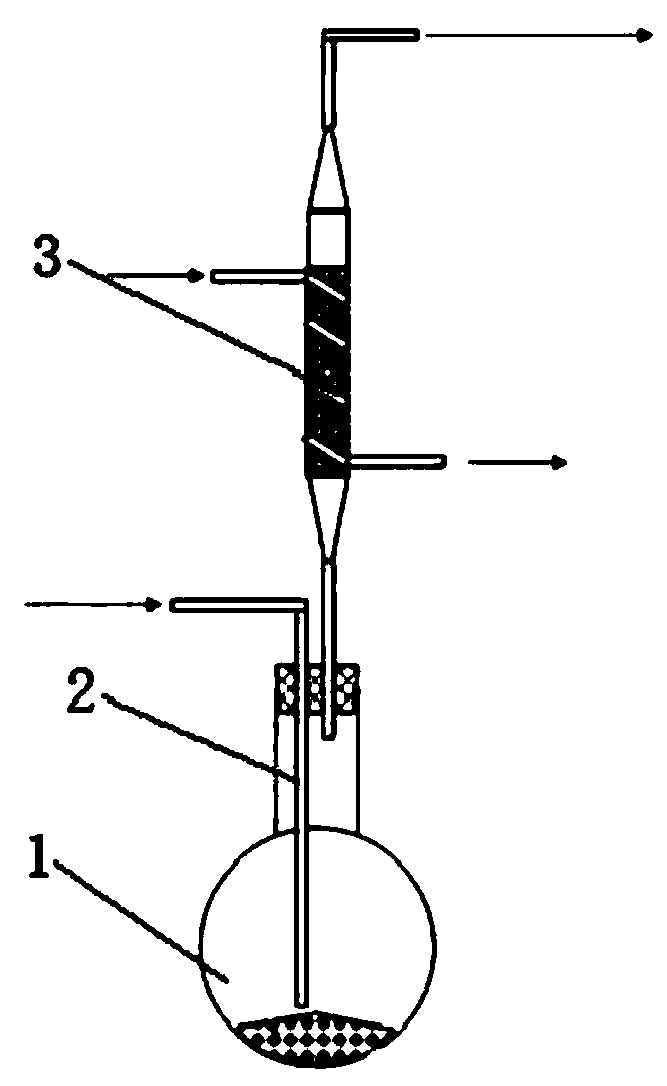

[0041] (2) 1g of elemental sulfur is put into a sealed container, and 1g of acetylene black porous carbon material is loaded inside the cooling device (condenser);

[0042] (3) Introduce nitrogen, and turn on the vacuum pump, adjust the gas cylinder and the vacuum pump valve to maintain -0.1Mpa in the sealed container, and keep it for 30s until the air in the entire device is completely eliminated;

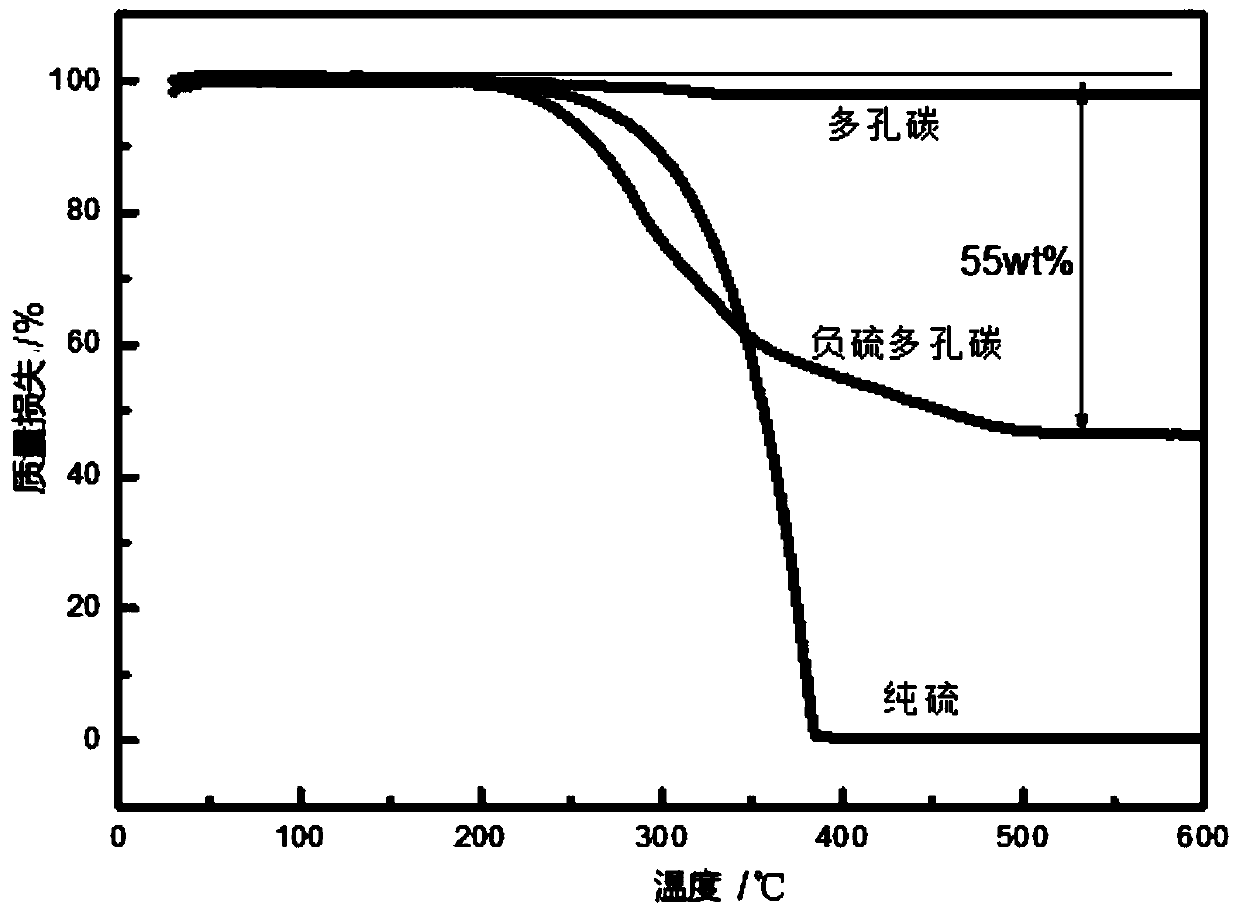

[0043] (4) Heat the sealed container to a temperature of about 500°C, the elemental sulfur in the sealed container is heated and sublimated into sulfur vapor, and the sulfur vapor enters the cooling device driven by negative pressure, and keeps for 1 second to fill the cooling device with s...

Embodiment 2

[0048] (1) Pretreatment of the mesoporous silicon material and the container conduit used: 100 g of the mesoporous silicon material, the container and the conduit used were cleaned with deionized water and put into a blast drying oven at 100°C for 24 hours. remove surface moisture;

[0049] (2) 100g of elemental iodine is put into a sealed container, and 100g of mesoporous silicon material is loaded inside the cooling device (multi-tube cooler);

[0050] (3) Introduce helium, turn on the vacuum pump, adjust the gas cylinder and the vacuum pump valve to maintain -10.0Mpa in the sealed container, and keep it for 30 minutes until the air in the entire device is completely eliminated;

[0051] (4) Use an electric heating mantle to heat the sealed container, the heating temperature is about 300°C, the elemental iodine in the sealed container is heated and sublimated into iodine vapor, and the iodine vapor enters the cooling device under negative pressure drive, and keeps for 10 min...

Embodiment 3

[0055] (1) Pretreatment of the zeolite molecular sieve and the used container conduit: wash the zeolite molecular sieve, the used container and the conduit with deionized water, and put them in a blast drying oven for 12 hours at 90°C to remove surface moisture;

[0056] (2) 10g elemental naphthalene is put into a sealed container, and 50g zeolite molecular sieve is loaded inside the cooling device (condenser);

[0057] (3) Introduce argon gas, turn on the vacuum pump, adjust the gas cylinder and the valve of the vacuum pump to maintain -1.0Mpa in the sealed container, and keep it for 10 minutes until the air in the entire device is completely eliminated;

[0058] (4) Use an alcohol lamp to heat the sealed container at a heating temperature of about 500°C. The elemental naphthalene in the container is heated and sublimated into naphthalene vapor, and the naphthalene vapor enters the cooling device under negative pressure drive, and keeps for 1 minute so that the naphthalene vap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com