A kind of preparation method of lithium-sulfur battery cathode material

A positive electrode material, lithium-sulfur battery technology, applied in the direction of battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of harsh process conditions, long load time, difficult to realize automatic process, etc., to achieve increased sulfur load, composite The effect of short time and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

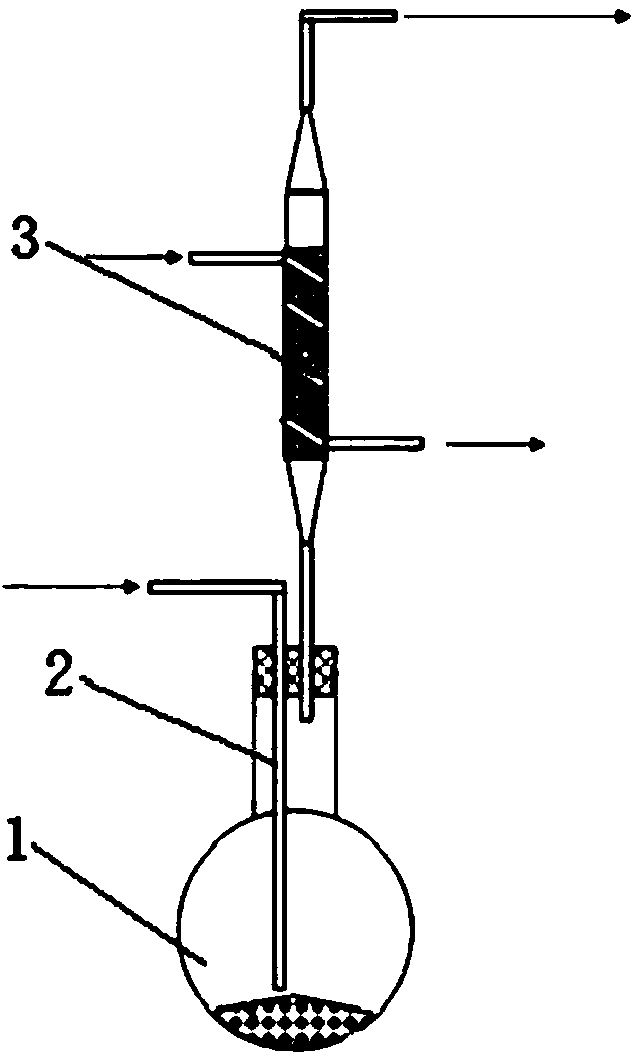

[0038] The preparation method of lithium-sulfur battery cathode material of the present invention, this method is based on evaporative cooling device, such as figure 1 As shown, the specific structure is: comprising a sealed container 1, the sealed container 1 is connected with a cooling device 3 and an inert gas pipe 2, and the cooling device 3 is connected with a vacuum pump; the cooling device 3 is a condensation pipe, a multi-tube cooler or a cooling tower;

[0039] The specific method is:

[0040] Step 1, add elemental sulfur into the sealed container 1, and load the pretreated porous carbon material in the cooling device 3; the pretreatment of the porous carbon material is to wash the porous carbon material with deionized water at 80-100 ° C Dry for 10-24 hours;

[0041] Step 2, feed an inert atmosphere into the sealed container 1 (the inert atmosphere is nitrogen, helium, neon, argon or xenon), and turn on the vacuum pump to keep the negative pressure -0.1~-10.0Mpa in ...

Embodiment 1

[0047] (1) Pretreatment of the acetylene black porous carbon material and the used container conduit: wash 1 g of the acetylene black porous carbon material and the used container and conduit with deionized water and put them in a blast drying oven to dry at 80°C 10h, remove surface moisture;

[0048] (2) 1g of elemental sulfur is put into a sealed container, and 1g of acetylene black porous carbon material is loaded inside the cooling device (condenser);

[0049] (3) Introduce nitrogen, and turn on the vacuum pump, adjust the gas cylinder and the vacuum pump valve to maintain -0.1Mpa in the sealed container, and keep it for 30s until the air in the entire device is completely eliminated;

[0050] (4) Heat the sealed container to a temperature of about 500°C, the elemental sulfur in the sealed container is heated and sublimated into sulfur vapor, and the sulfur vapor enters the cooling device driven by negative pressure, and keeps for 1 second to fill the cooling device with s...

Embodiment 2

[0056] (1) Pretreatment of the phenolic resin pyrolysis porous carbon material and the container conduit used: 100g of the phenolic resin pyrolysis porous carbon material and the container and conduit used were cleaned with deionized water and placed in a blast drying oven Dry at 100°C for 24 hours to remove surface moisture;

[0057] (2) 100g of elemental sulfur is put into a sealed container, and 100g of phenolic resin pyrolysis porous carbon material is loaded inside the cooling device (multi-tube cooler);

[0058] (3) Introduce helium, turn on the vacuum pump, adjust the gas cylinder and the vacuum pump valve to maintain -10.0Mpa in the sealed container, and keep it for 30 minutes until the air in the entire device is completely eliminated;

[0059] (4) Use an electric heating mantle to heat the sealed container, the heating temperature is about 300°C, the elemental sulfur in the sealed container is heated and sublimated into sulfur vapor, and the sulfur vapor enters the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com