High-yield-strength aluminum alloy formula and smelting key device thereof

An aluminum alloy, high-yield technology, applied in the field of aluminum alloy, can solve the problems that limit the development of high-speed and high-power automobiles, and the yield strength performance is not ideal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The formula of the high-yield-strength aluminum alloy provided in this embodiment is by weight percentage:

[0031] Si: 0.3%~9%; Fe: 0.6~1.3%; Cu: 0.1~2.5%; Mn: 0~1.8%; Mg: 0~1.5%; Ni: 0~0.7%; Ti: 0~0.1%; Sb: 0-0.1%; Zn: 2-19%; Pb: 0-0.01%; the balance is Al.

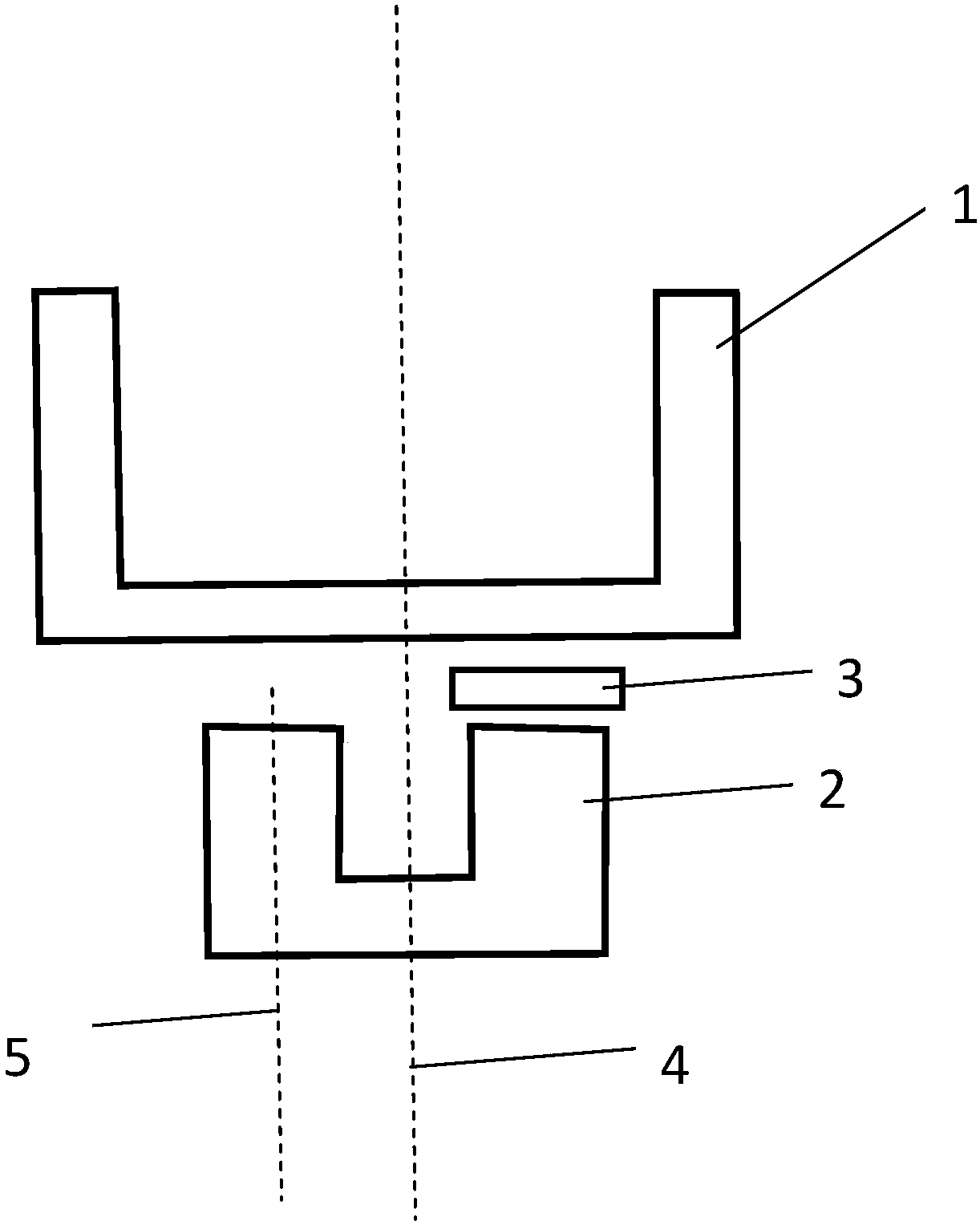

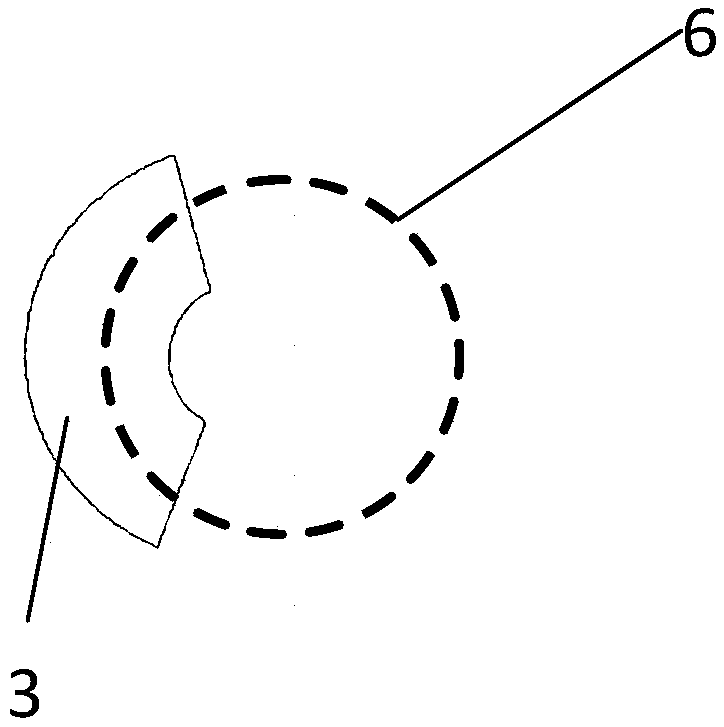

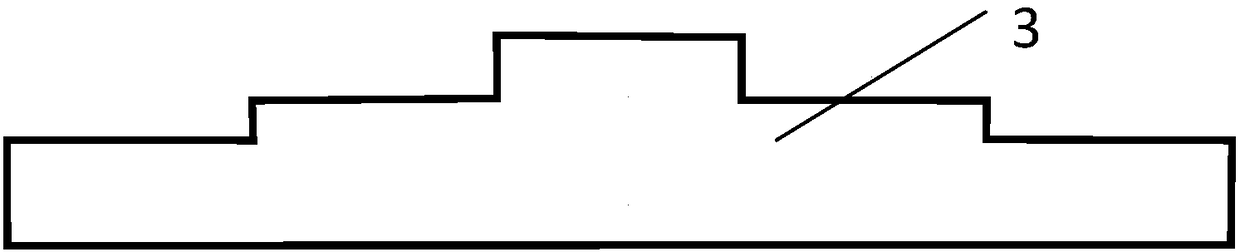

[0032] The key smelting technology of this embodiment includes a surge-type permanent magnetic stirring device, including a melting furnace 1, a permanent magnetic stirring magnet 2, and a permanent magnetic partition 3. The permanent magnetic partition 3 is located near the bottom of the melting furnace 1 and is located at the permanent magnetic stirring magnet 2. Above, the magnetization direction of the permanent magnet separator 3 is perpendicular to the plane of the permanent magnet separator 3, the area of the permanent magnet separator 3 is less than the area of the bottom of the smelting furnace 1, and the magnetic field strength of the permanent magnet separator 3 is less than that of the permanent m...

Embodiment 2

[0034] Figure 4 The permanent magnet separator shown is square, and other parameters are the same as in Embodiment 1.

Embodiment 3

[0036] Figure 5 The permanent magnet separator shown is in rhombus shape, and other parameters are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com