Low-speed and high-torque motor with magnetic gear

A magnetic gear, high torque technology, applied in the direction of magnetic circuit rotating parts, synchronous motors with static armatures and rotating magnets, magnetic circuit static parts, etc., can solve the problem of increasing the cost of the motor and increasing the outer gas gap length, reducing the coupling degree between the magnetic field of the armature group and the permanent magnetic field of the inner rotor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0019] In this application document, unless otherwise specified, the orientation words used such as "upper and lower" usually refer to the upper and lower as shown in the drawings; The inside and outside of the silhouette.

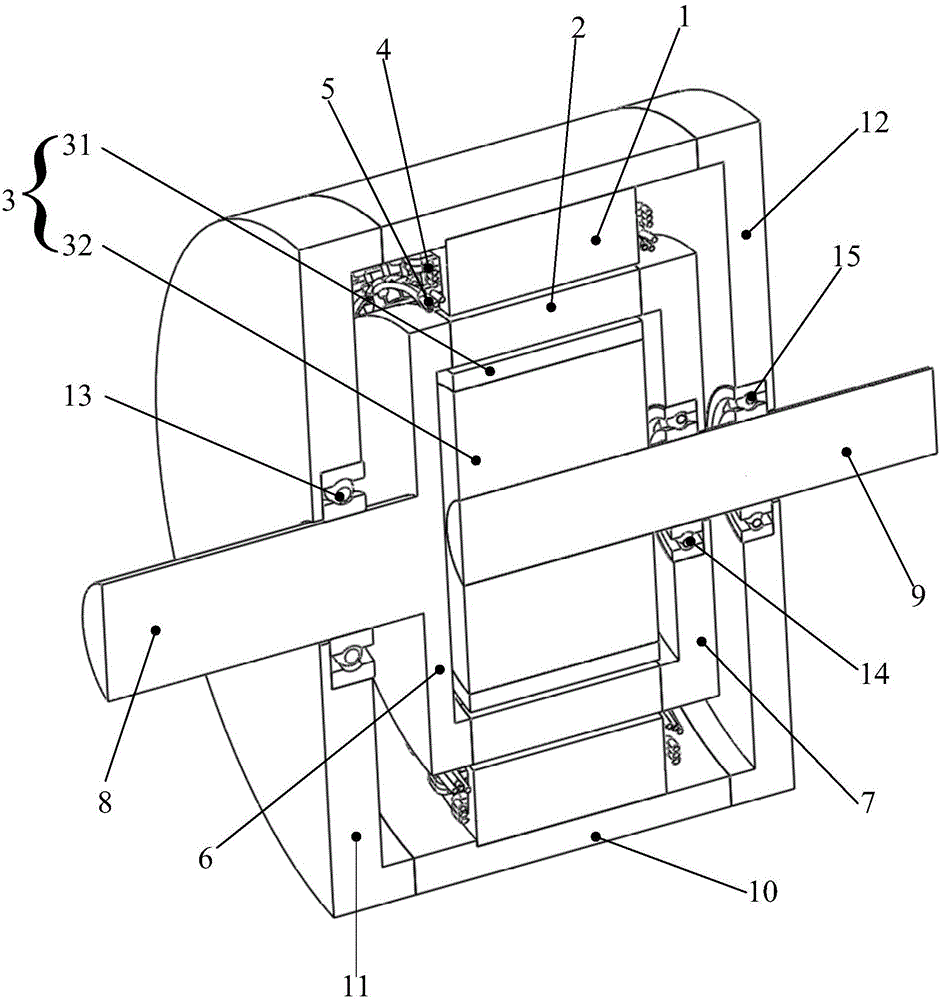

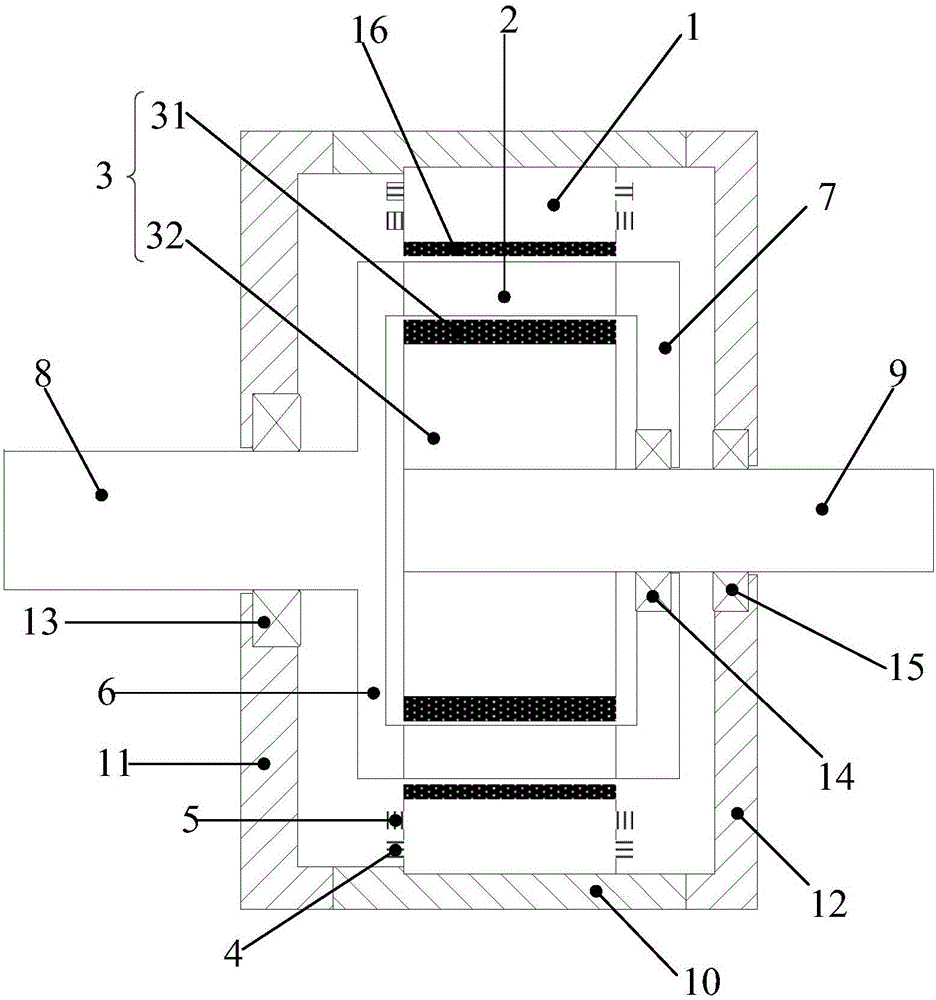

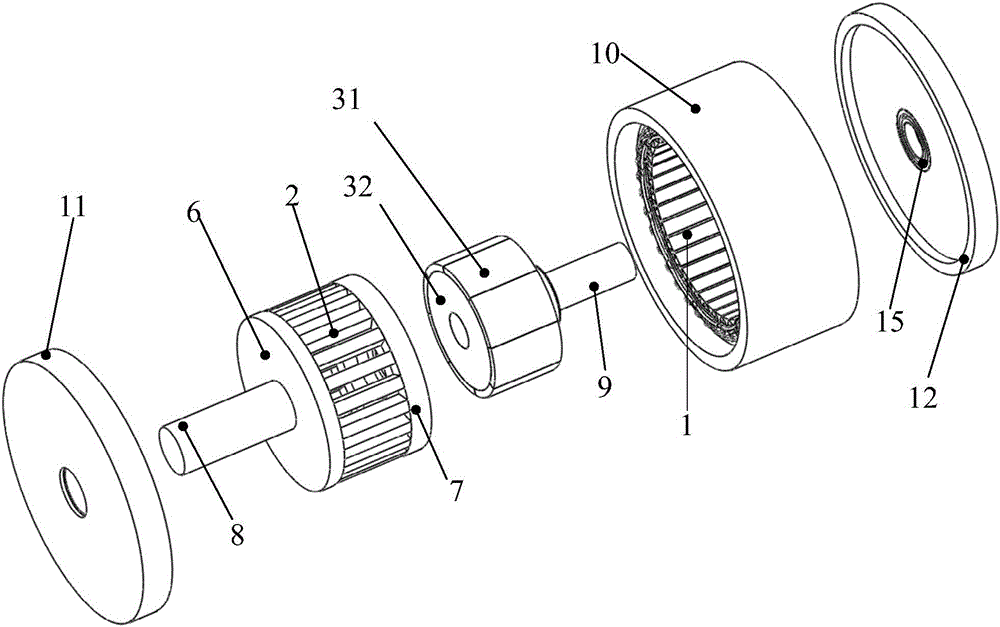

[0020] Please refer to Figure 1a and Figure 1b , is a planing structure schematic diagram and a plane structure schematic diagram of a magnetic gear low-speed high-torque motor disclosed in this embodiment. The magnetic gear low-speed high-torque motor includes: an inner rotor 3 arranged coaxially from the inside to the outside, and a magnetization ring 2 and stator 1. Wherein, the inner rotor 3 is provided with a permanent magnet; the stator 1 is provided with an armature winding 5 that generates a rotating magnetic field, and the stator 1 is also provided with an electromagnet 4 that generates a constant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com